Low-density superfine silver-coated aluminum composite flexible wire and preparation method thereof

A silver-clad aluminum, low-density technology, applied in the direction of cable/conductor manufacturing, equipment for manufacturing conductive/semiconductive layers, root rod/rod/wire/strip conductor, etc., can solve the problem of damage to material processing performance and physical properties , thick wire diameter, high density, etc., to achieve the effect of easy control of film thickness, good adhesion, and uniform and dense silver plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

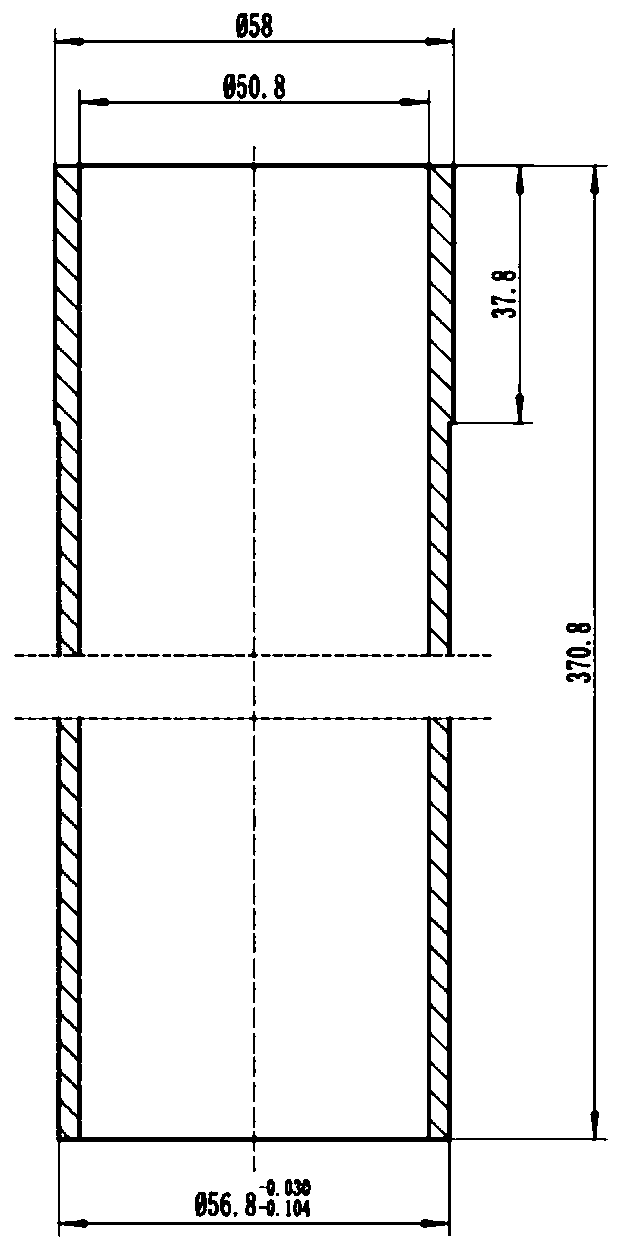

[0041] The outer diameter is Φ10μm, the inner diameter is Φ8.4μm, the cladding thickness is 0.8μm (the cladding thickness ratio is 8%), and the density is 5g / cm 3 Preparation of silver-clad aluminum composite soft wire:

[0042] The silver tube target is used as the cathode, the pure aluminum core material Φ15μm with continuous wiring (40mm / min) is used as the anode, and the vacuum degree is 0.6×10 -3 Pa, filled with high-purity argon gas 0.6MPa, working target current 5A, the average thickness of the film is controlled at 1.54μm, the silver-clad aluminum composite wire billet is prepared, and the composite wire billet is deformed by 3-4% per pass, the total deformation 70%, the uniform and dense silver composite layer is prepared with an outer diameter of Φ10μm, an inner diameter of Φ8.4μm, a layer thickness of 0.8μm (layer thickness ratio of 8%), and a density of 5g / cm 3 Silver-clad aluminum composite soft wire.

Embodiment 2

[0044] The outer diameter is Φ30μm, the inner diameter is Φ27.3μm, the thickness of the clad layer is 1.35μm (the thickness ratio of the clad layer is 4.5%), and the density is 4g / cm 3 Preparation of silver-clad aluminum composite soft wire:

[0045] The silver tube target is used as the cathode, the pure aluminum core material Φ45μm with continuous wiring (50mm / min) is used as the anode, and the vacuum degree is 0.8×10 -3 Pa, filled with high-purity argon gas 0.5MPa, working target current 4A, the average thickness of the film is controlled at 2.45μm, and the silver-clad aluminum composite wire billet is prepared, and the composite wire billet is deformed by 4-5% per pass, and the total deformation 64%, the uniform and dense silver composite layer is prepared with an outer diameter of Φ30μm, an inner diameter of Φ27.3μm, a layer thickness of 1.35μm (layer thickness ratio of 4.5%), and a density of 4g / cm 3 Silver-clad aluminum composite soft wire.

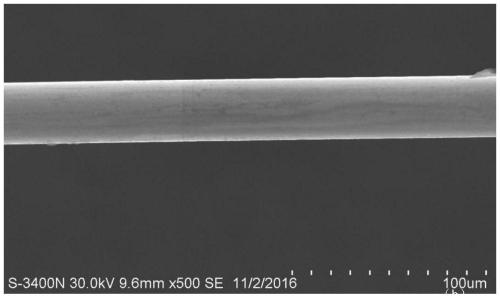

[0046] From figure 2 It...

Embodiment 3

[0048] Silver-clad aluminum composite soft wire, the outer diameter is Φ50μm, the inner diameter is Φ49μm, the thickness of the cladding layer is 0.5μm (thickness ratio of the cladding layer is 1%), and the density is 3g / cm 3 Preparation of silver-clad aluminum composite soft wire:

[0049] The silver tube target is used as the cathode, the pure aluminum core wire Φ75μm of continuous wiring (60mm / min) is used as the anode, and the vacuum degree is 1×10 -3 Pa, filled with high-purity argon gas 0.3MPa, working target current 3A, the average thickness of the film is controlled at 0.92μm, the silver-clad aluminum composite wire billet is prepared, and the composite wire billet is deformed by 5-6% per pass, the total deformation 58%, the uniform and dense silver composite layer is prepared with an outer diameter of Φ50μm, an inner diameter of Φ49μm, a layer thickness of 0.5μm (layer thickness ratio of 1%), and a density of 3g / cm 3 Silver-clad aluminum composite soft wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com