Vibration monitoring system for transformer

A vibration monitoring system and transformer technology, applied in vibration testing, signal transmission systems, non-electrical signal transmission systems, etc., can solve the problems of difficulty in determining the precise time of detection sensors, poor anti-interference performance, and inability to synchronize data acquisition of all channels, etc. Achieve the effects of high dynamic range, high SNR, and enhanced anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited by this.

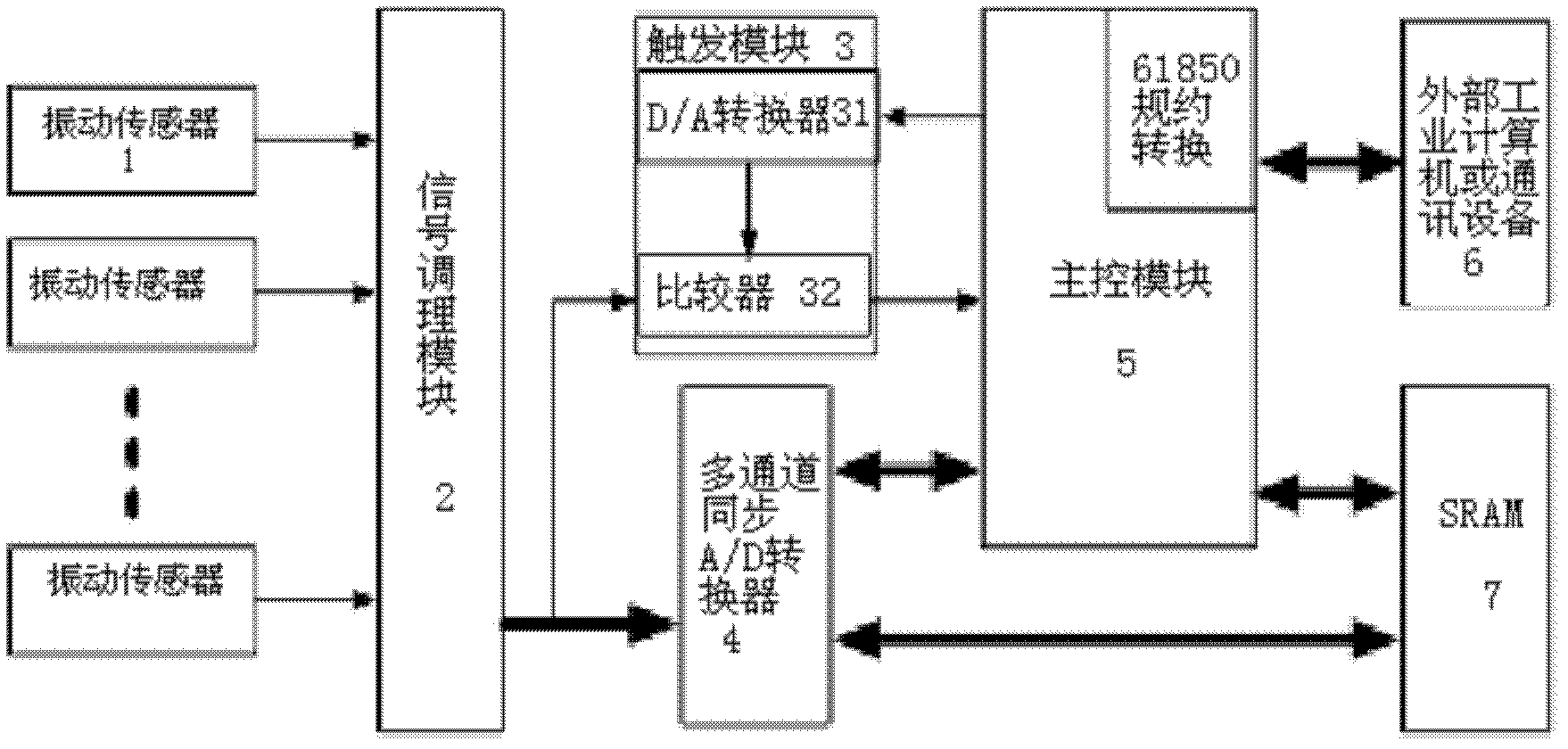

[0028] see first figure 1 , figure 1 It is a schematic structural diagram of the transformer vibration monitoring system of the present invention. As shown in the figure, the transformer vibration monitoring system of the present invention includes: six vibration sensors 1, a signal conditioning module 2, a trigger module 3, a multi-channel A / D converter 4, The main control module 5, the external industrial computer 6 and the high-speed static cache module 7; the connection relationship of the above components is as follows:

[0029] The six vibration sensors 1 are respectively arranged on the six vibration test points of the transformer to be tested, and the output signal connectors of the six vibration sensors 1 are respectively connected with the six input signal connecto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency range | aaaaa | aaaaa |

| Resolution | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com