Hanging rammer type lunar soil section simulated preparation device

A preparation device and profile technology, which is applied in the field of lunar soil profile simulation preparation devices, can solve problems such as the inability to ensure the distribution gradient of lunar soil density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

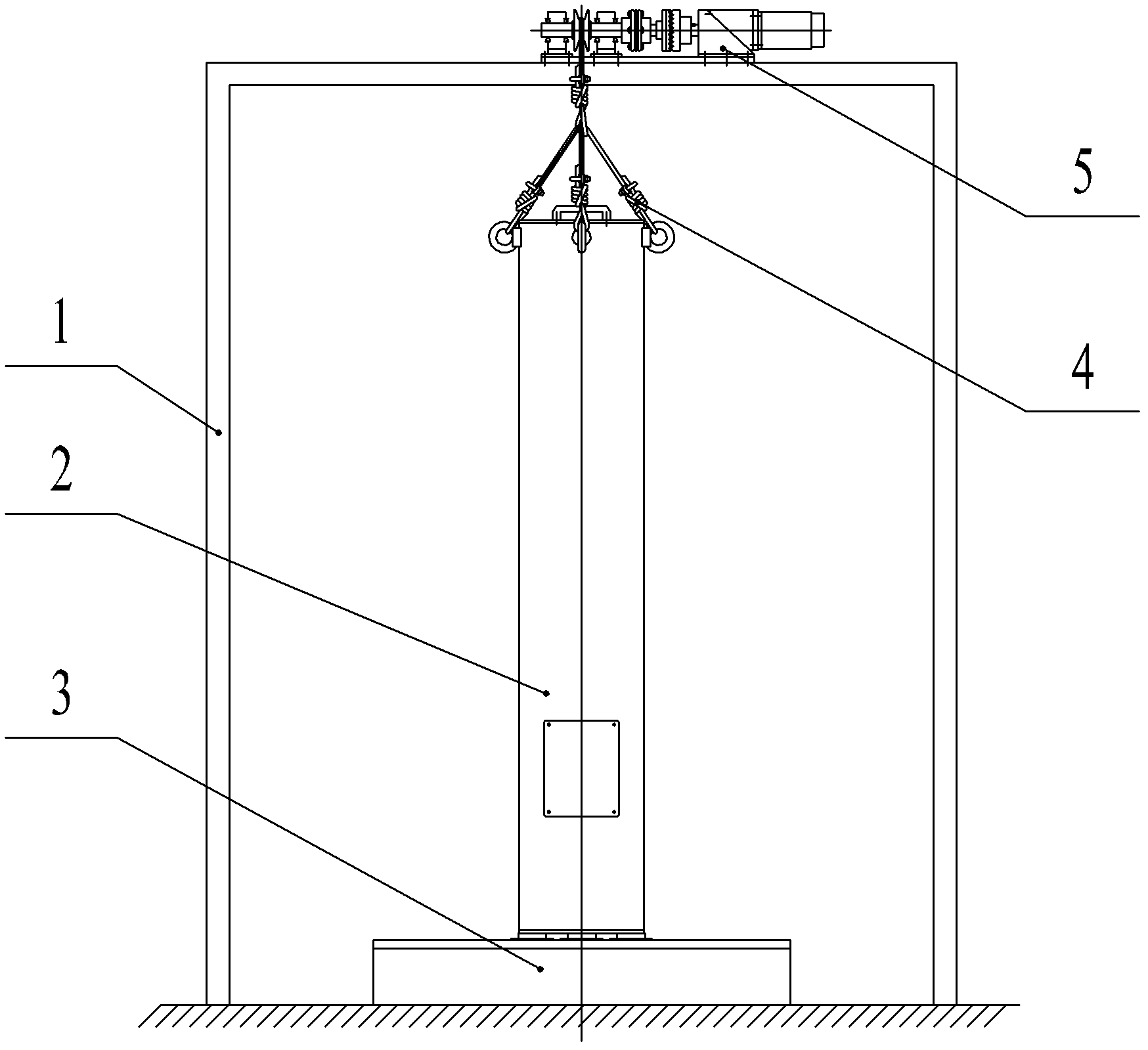

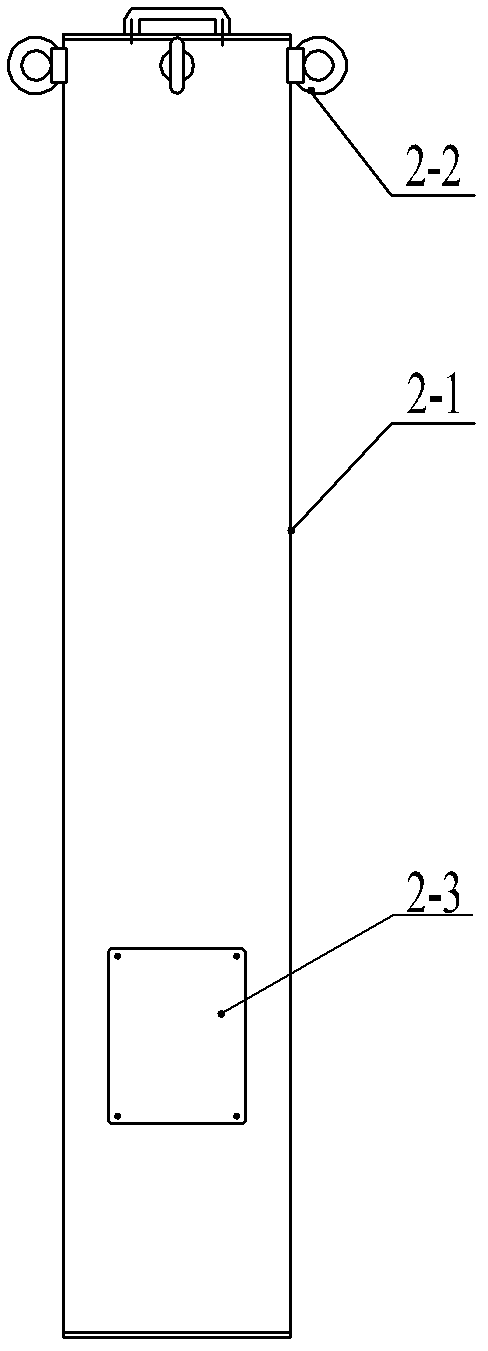

[0007] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, the device of this embodiment includes portal support 1, simulated lunar soil bucket 2, chopping board 3, hoisting rope 4 and hanging rammer mechanism 5, simulated lunar soil bucket 2 and chopping board 3 are arranged in portal bracket 1 , the simulated lunar soil bucket 2 includes a bucket body 2-1, a soil unloading cover 2-3 and two lifting lugs 2-2. At the soil unloading port of the barrel body 2-1 and detachably connected with the barrel body 2-1, two lifting lugs 2-2 are installed on the upper part of the barrel body 2-1, and the simulated lunar soil barrel 2 is installed above the cutting board 3 , the hanging rammer mechanism 5 consists of encoder 5-1, servo motor 5-2, planetary gear reducer 5-3, reducer support seat 5-4, electromagnetic clutch 5-5, elastic coupling 5-6, from right The heavy shaft support seat 5-7, the lifting pulley shaft 5-8, the hanging rammer mounting plat...

specific Embodiment approach 2

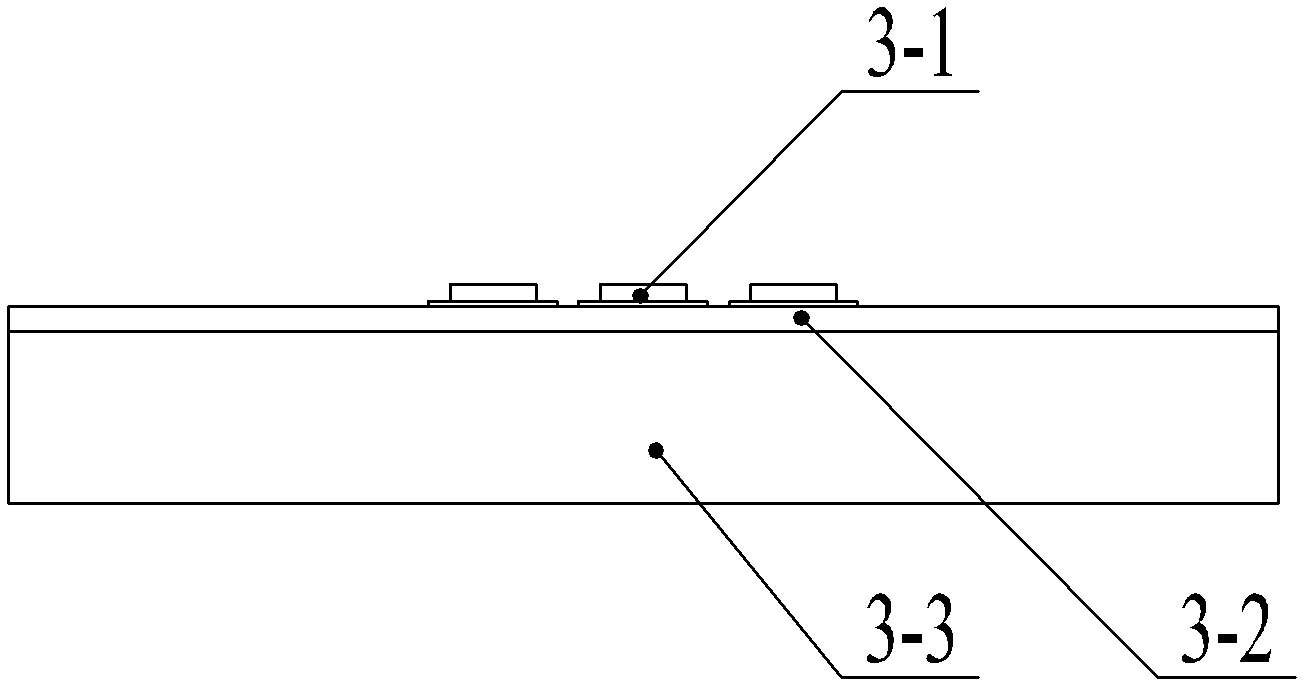

[0008] Specific implementation mode two: combination image 3 Describe this embodiment, the chopping block 3 of this embodiment is made up of striker connecting plate 3-2, soft skid 3-3 and a plurality of metal striker 3-1, and a plurality of metal striker 3-1 is evenly installed on striker connecting plate 3 -2, the soft skid 3-3 is inlaid on the lower end of the striker connecting plate 3-2, when the simulated lunar soil bucket 2 impacts downward, since the metal striker 3-1 and the bottom of the simulated lunar soil bucket 2 are both rigid Parts can make the simulated lunar soil achieve a better compaction effect under the action of rigid impact, and inlaying the soft skid 3-3 under the striker connecting plate 3-2 can reduce the damage to the simulated lunar soil bucket 2 during multiple impacts. ground damage. Other implementation manners are the same as the specific implementation manner 1.

[0009] Working principle: energize the electromagnetic clutch 5-5, then start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com