Sintering mould

A mold and mold height technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of increasing equipment costs and use costs, poor pressure resistance of graphite molds, easy cracking of graphite molds, etc. The effect of increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

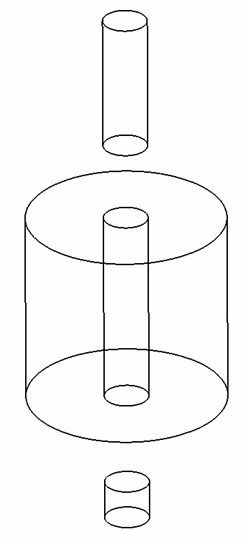

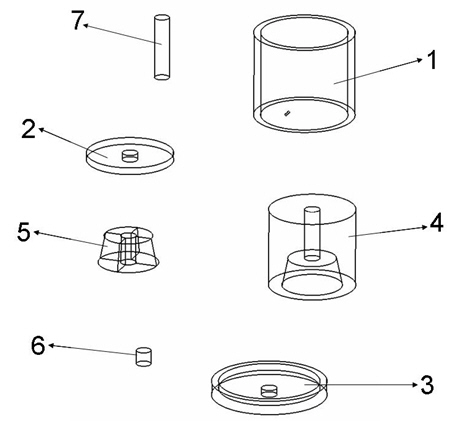

[0020] The structure diagram of the present invention is as figure 2 As shown, the sintering mold of the present invention includes an outer sleeve 1, a bottom cover 2, a top cover 3, an upper mold 4, a lower mold 5, a lower graphite rod 6, and an upper graphite rod 7, wherein the bottom cover 2 and the top cover 3 Installed on the bottom and top of the outer sleeve 1 respectively, the lower mold 5 is placed in the hollow cavity provided by the outer sleeve 1 and placed on the bottom cover 2, the lower part of the upper mold 4 is set on the outside of the lower mold 5, and the lower mold The rod 6 is inserted in the cavity provided by the lower die 5 , and the upper graphite rod 7 is inserted in the cavity provided on the top of the upper die 4 and placed on the top of the lower graphite rod 6 .

[0021] Above-mentioned lower die 5 is a conical circular frustum with a small upper part and a larger lower part.

[0022] Above-mentioned lower mold 5 is assembled into conical ci...

example 1

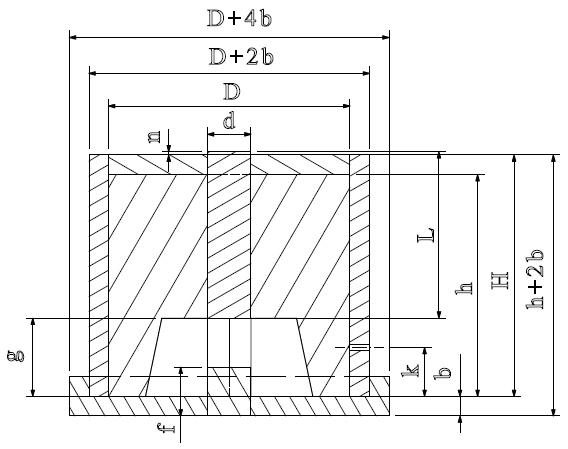

[0033] Example 1: The material of the outer sleeve 1 is corundum. If the sample diameter d is 5mm and the height is 2mm, figure 2 The diameter of middle and lower graphite rod 6 and upper graphite rod 7, the inner diameter of bottom cover 2, top cover 3 upper die 4, lower die 5 all get 5mm. The outer diameter D of the upper mold 4 is 50 mm. The outer diameter of the bottom of the lower mold 5 is 12.5mm. The thickness b of the outer sleeve 1, the bottom cover 2 and the top cover 3 is 4mm. The inner diameter of the outer sleeve 1 and the outer diameter of the top cover 3 are 50mm. The inner diameter of the wall of the bottom cover 2 is 58 mm and the outer diameter is 66 mm. The length f of the lower graphite rod 6 is 5mm. The height g of the lower mold 5 is 3 mm, and the angle between the side of the lower mold 5 and the vertical direction is 5 mm. o . The graphite mold height h is 30mm. The length L of the upper graphite rod 7 is 35 mm, and the length n of the graphite...

example 2

[0034] Example 2: The material of the outer sleeve 1 is zirconia. If the sample diameter d is 100mm and the height is 4mm, figure 2The diameter of middle and lower graphite rod 6 and upper graphite rod 7, the inner diameter of bottom cover 2, top cover 3 upper die 4, lower die 5 all get 100mm. The outer diameter D of the upper mold 4 is 200mm. The outer diameter of the bottom of the lower mold 5 is 100mm. The thickness b of the outer sleeve 1, the bottom cover 2 and the top cover 3 is 2 mm. The inner diameter of the outer sleeve 1 and the outer diameter of the top cover 3 are 200mm. The inner diameter of the wall of the bottom cover 2 is 204mm, and the outer diameter is 208mm. The length f of the lower graphite rod 6 is 8 mm. The height g of the lower die 5 is 10 mm, and the angle between the side of the lower die 5 and the vertical direction is 15 mm. o . The graphite mold height h is 40mm. The length L of the upper graphite rod 7 is 40 mm, and the length n of the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com