Alkaline development plate punching waste water treating method and development treating method of planographic plate material

A lithography, wastewater treatment technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of increased conductivity of wastewater, unsatisfactory precipitation effect, and unusable use. , to achieve the effect of long service life, good electrolysis effect and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

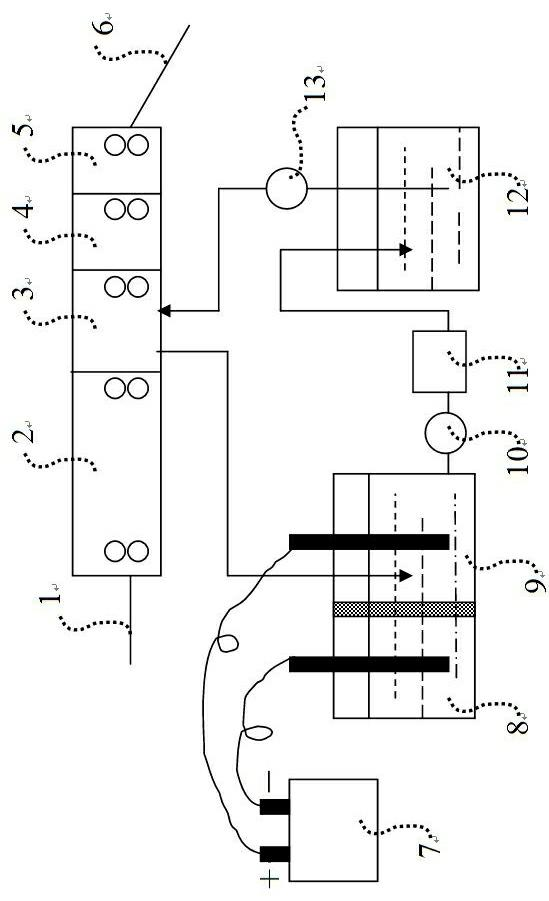

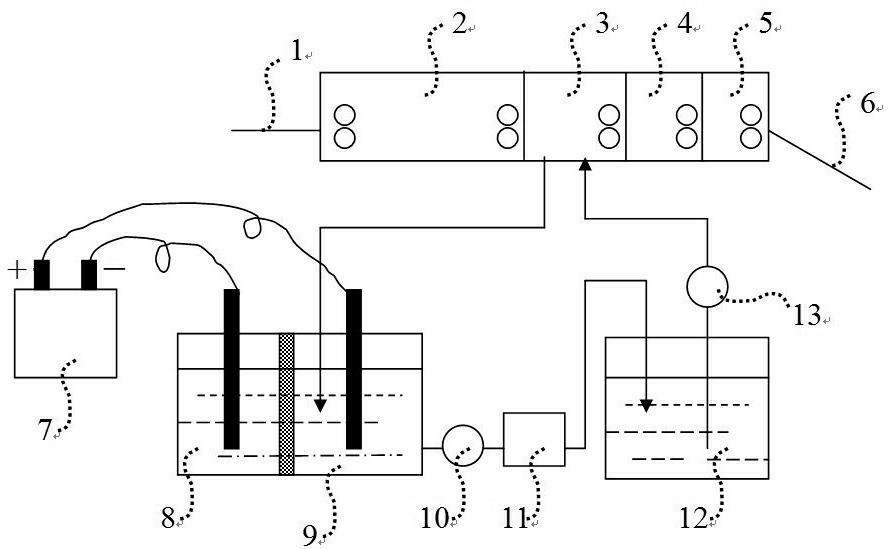

[0064] As a preferred embodiment of the present invention, the present invention discloses a method for treating alkaline developing plate-washing wastewater of lithographic printing plates, comprising the following steps:

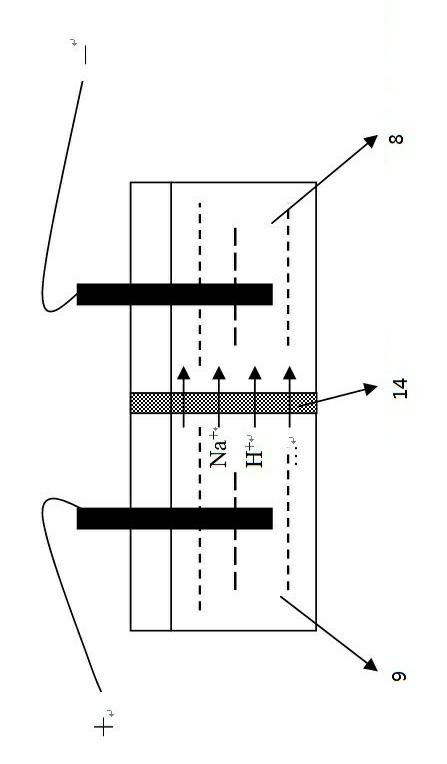

[0065] (1) In the electrolytic cell separated by the cationic membrane 14, through the effect of direct current, the alkaline developing plate-washing wastewater is electrolyzed at the anode of the electrolytic cell to produce acid or metal ions to neutralize the alkaline developing plate-washing wastewater Alkali or basic salt, so that the basic salt forms a precipitate together with the organic resin and colored dye dissolved in the alkaline developing plate wastewater;

[0066] (2) filter the precipitate formed;

[0067] (3) The filtered clean water is returned to the developing and flushing unit 3 for recycling.

Embodiment 2

[0069] As another preferred embodiment of the present invention, the present invention discloses a method for developing and treating lithographic printing plates, including the step of developing and treating the offset lithographic printing plates, and performing the rinsing process on the developed printing plates. step, the step of carrying out glue preservation and drying treatment on the washed printing plate, and also includes a method for treating alkaline developing plate-washing wastewater, the method comprising:

[0070] (1) In the electrolytic cell separated by the cationic membrane 14, through the effect of direct current, the alkaline developing plate-washing wastewater is electrolyzed at the anode of the electrolytic cell to produce acid or metal ions to neutralize the alkaline developing plate-washing wastewater Alkali or basic salt, so that the basic salt forms a precipitate together with the organic resin and colored dye dissolved in the alkaline developing pl...

Embodiment 3

[0074] As another preferred embodiment of the present invention, the present invention discloses a wastewater treatment device for alkaline development of lithographic printing plates, including an electrolytic cell separated by a cationic membrane 14, an anode electrode, a cathode electrode, and a direct current generator 7. Filtration pump 10 and filter device 11; wherein, in the electrolytic cell separated by cationic membrane 14, cationic membrane 14 divides the electrolytic cell into two electrolytic cells of negative and positive, and the positive electrode is arranged in the positive electrolytic cell 9, and the positive electrode is arranged in the positive electrolytic cell 9. The electrode is arranged in the negative electrolytic cell 8, the anode of the direct current generator 7 is connected to the positive electrode, the negative electrode of the direct current generator 7 is connected to the negative electrode, one end of the filter pump 10 is connected to the nega...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com