Optical and thermal-oxidative dual-degradation plastic thin film and manufacturing method thereof

A plastic film, double degradation technology, applied in the field of chemical industry, to achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

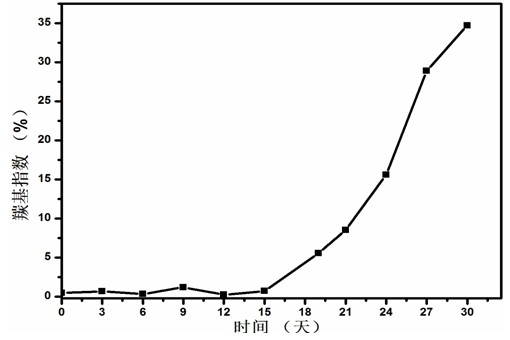

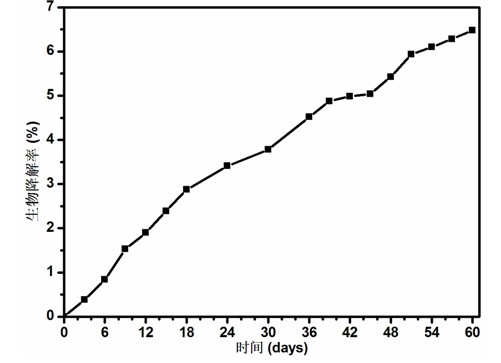

[0035] Preparation and performance test of photo-thermal-oxygen double-degradable plastic film.

[0036] 1. Preparation of photo-thermal-oxygen dual degradation masterbatch: nano-TiO 2 (P25 imported from Germany, domestic sub-packaging), iron carboxylate (Shandong Gaomi Youhe Additives Co., Ltd.), polyethylene micropowder (Jiangyin Ideal Plastic Technology Co., Ltd., Jiangsu Province), oxidized polyethylene wax (Gu Shandong Fengshen Chemical Co., Ltd.) according to the mass ratio of 1:1:1:4 to mix evenly, and then melt extrusion granulation.

[0037] 2. Preparation of light-thermo-oxygen double-degradable plastic film: Mix the degradation masterbatch obtained in 1 with linear low-density polyethylene particles (Sinopec Zhongyuan Petrochemical Co., Ltd.) at a mass ratio of 7:93. At this time, the catalyst The mass content in the film is 1%, and then blown into a film. The thickness of the resulting film was 25±5 μm.

[0038] The mechanical properties of the film prepared above...

Embodiment 2

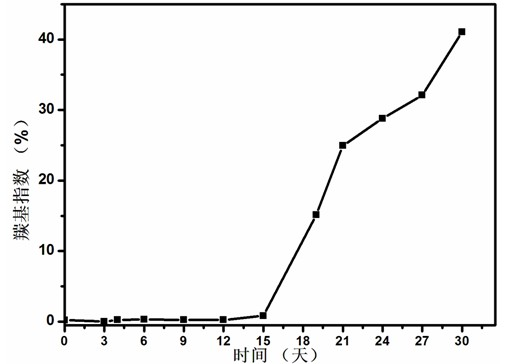

[0046] Preparation and performance test of photo-thermal-oxygen double-degradable plastic film.

[0047] 1. Preparation of photo-thermal-oxygen dual degradation masterbatch: TiO 2 (P25 imported from Germany, subpackaged in China), manganese carboxylate (Shandong Gaomi Youhe Additives Co., Ltd.), polyethylene micropowder (Jiangyin Ideal Plastic Technology Co., Ltd., Jiangsu Province), oxidized polyethylene wax (Gu Shandong Fengshen Chemical Co., Ltd.) according to the mass ratio of 1:1:1:4 to mix evenly, and then melt extrusion granulation.

[0048] 2. Preparation of light-thermo-oxygen double-degradable plastic film: The method is the same as that in Example 1 (linear low-density polyethylene is also used).

[0049] 3. The mechanical properties of the film prepared above were tested according to the method of GBT 1040.3-2006, and its elongation at break and tensile strength were slightly lower than those of pure polyethylene film, which were 311% and 142MPa, respectively. The re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com