Preparation method of multifunctional light-conversion thin film added with rare earth

A film preparation and multi-functional technology, which is applied in the fields of botany equipment and methods, greenhouse cultivation, climate change adaptation, etc., can solve the problems of few varieties of functional "agricultural film, narrow application area, etc., and achieve good light conversion and thermal insulation performance. , improve leaf area and development, and promote the effect of vegetative growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

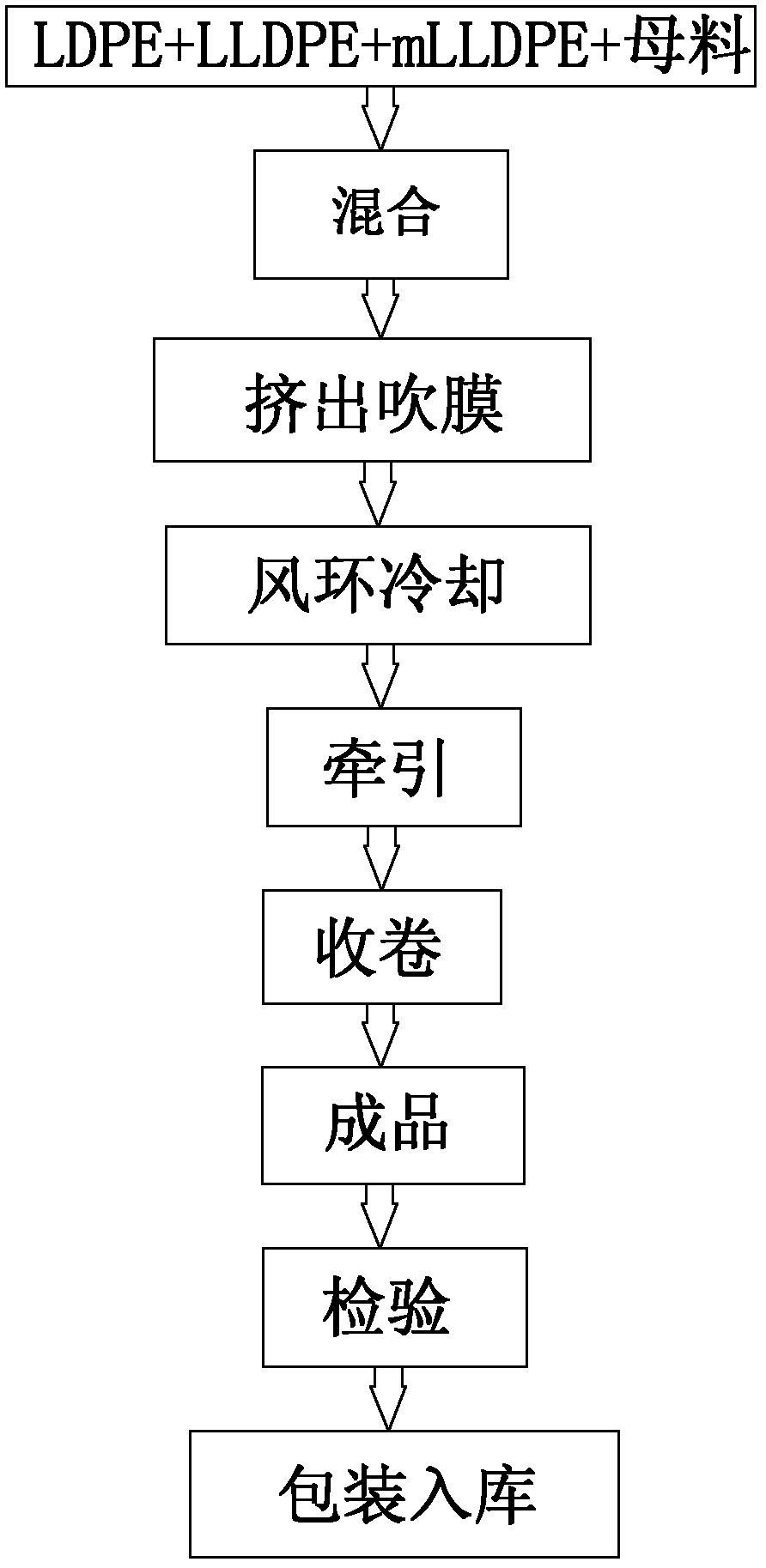

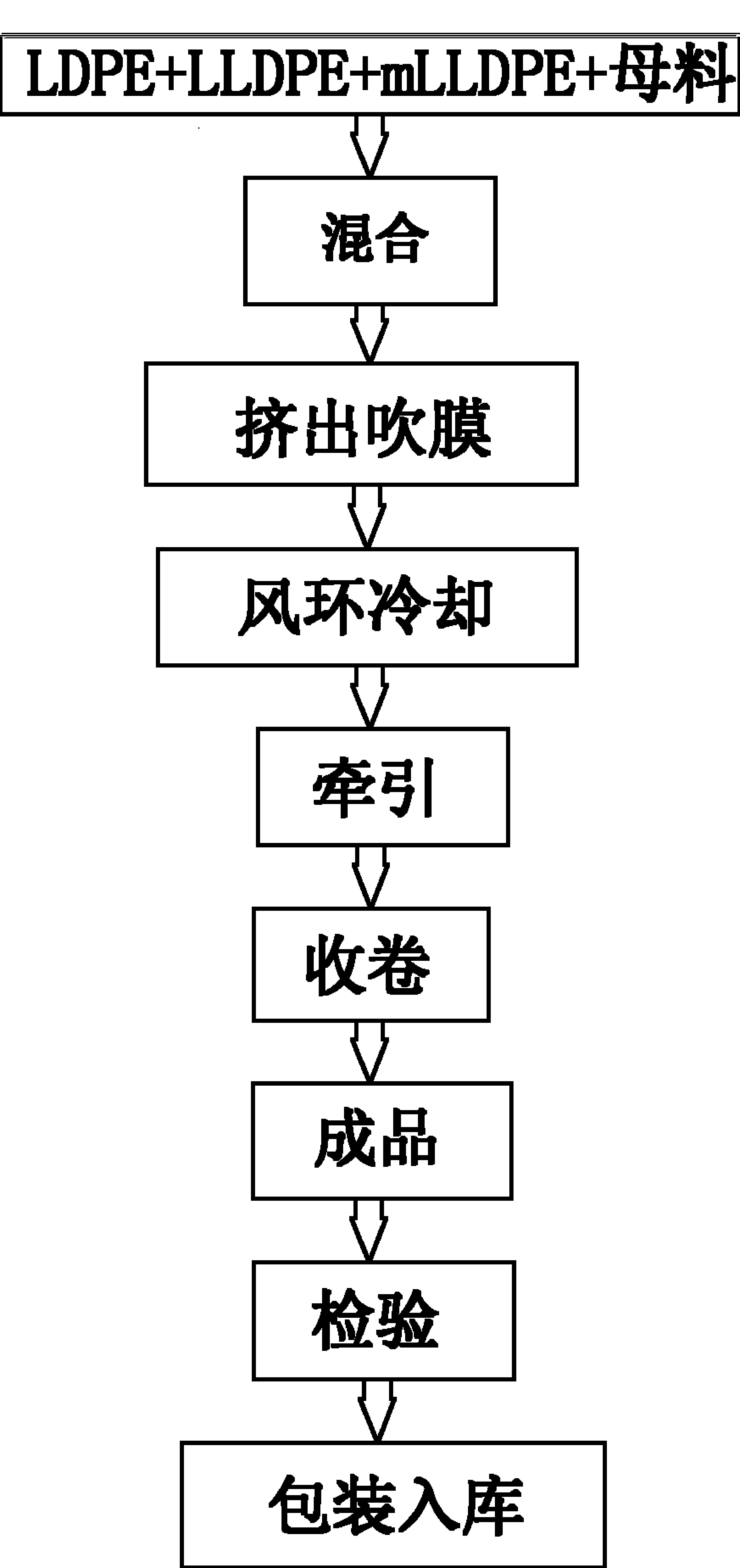

[0016] A method for preparing a multifunctional light-converting film with rare earth added, comprising low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), metallocene polyethylene (mLLDPE), rare earth light conversion agent, anti-aging agent, anti-fog The drop component constitutes, and the preparation method specifically includes the following steps, such as figure 1 as shown,

[0017] 1. Preparation of masterbatch:

[0018] First, mix LDPE, rare earth light conversion agent, anti-aging agent and anti-fogging agent and dry it. After drying, it is extruded and granulated by a granulator, and then the granules are dried and sieved to obtain the masterbatch;

[0019] 2. Mix LDPE, LLDPE, mLLDPE and masterbatch, extrude and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com