Five-drill air inlet and outlet type coal mining machine

A wind-in and out-flow, five-bit technology, which is applied in the direction of drill bits, earth square drilling, mechanical equipment, etc., can solve the problem of low cutting efficiency of three-bit drilling shearers, low adaptability to gas-containing coal seam mining, and limitations of shearer drilling. In order to improve the recovery rate of coal resources, reduce the energy consumption of mining, and achieve the effect of extensive practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

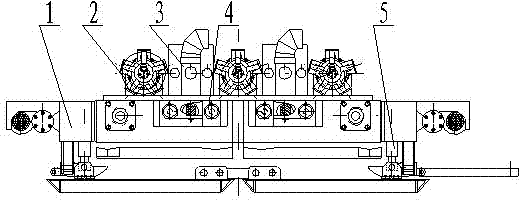

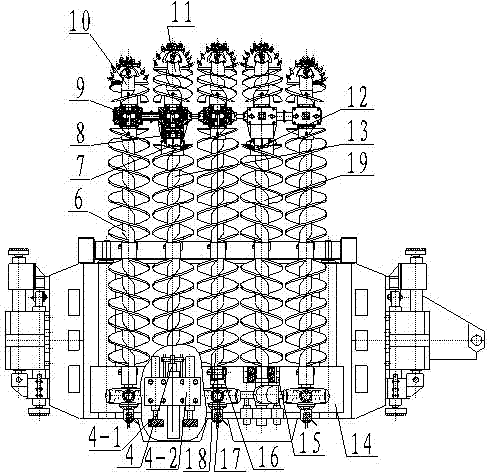

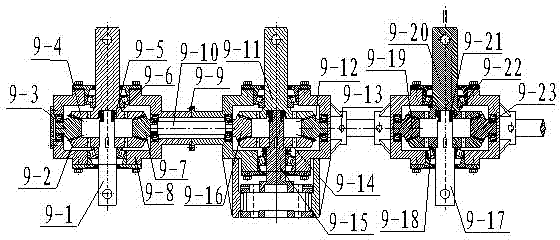

[0013] Such as figure 1 , figure 2 As shown, the five-bit in and out pneumatic coal mining machine of the present invention is mainly composed of a bracket 1, a first hydraulic motor 2, a ventilator 3, a hydraulic propulsion cylinder 4, a height adjustment device 5, a lateral transmission drill rod 6, and a blower fan 7. Planetary mechanism 8, bevel gear transmission box 9, short spiral drill bit 10, long spiral drill bit 11, exhaust fan 12, left ventilation drill rod 13, moving frame 14, bearing seat 15, coupling 16, second hydraulic motor 17 , The center transmission drill rod 18 and the right ventilation drill rod 19 are constituted. The lower part of the bracket 1 is provided with a height-adjusting device 5. The height-adjusting device 5 realizes the height adjustment of the bracket 1 through a hydraulic cylinder. The bracket 1 is provided with a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com