Method for fixing a mounting element to a photovoltaic module

A technology for installing components and photovoltaic modules, applied to the support structure of photovoltaic modules, photovoltaic modules, photovoltaic power generation, etc., can solve the problems of manual steps that cannot be reproduced, complicated installation process, and increased labor costs, and achieve rapid single-piece product production Time, high throughput, and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

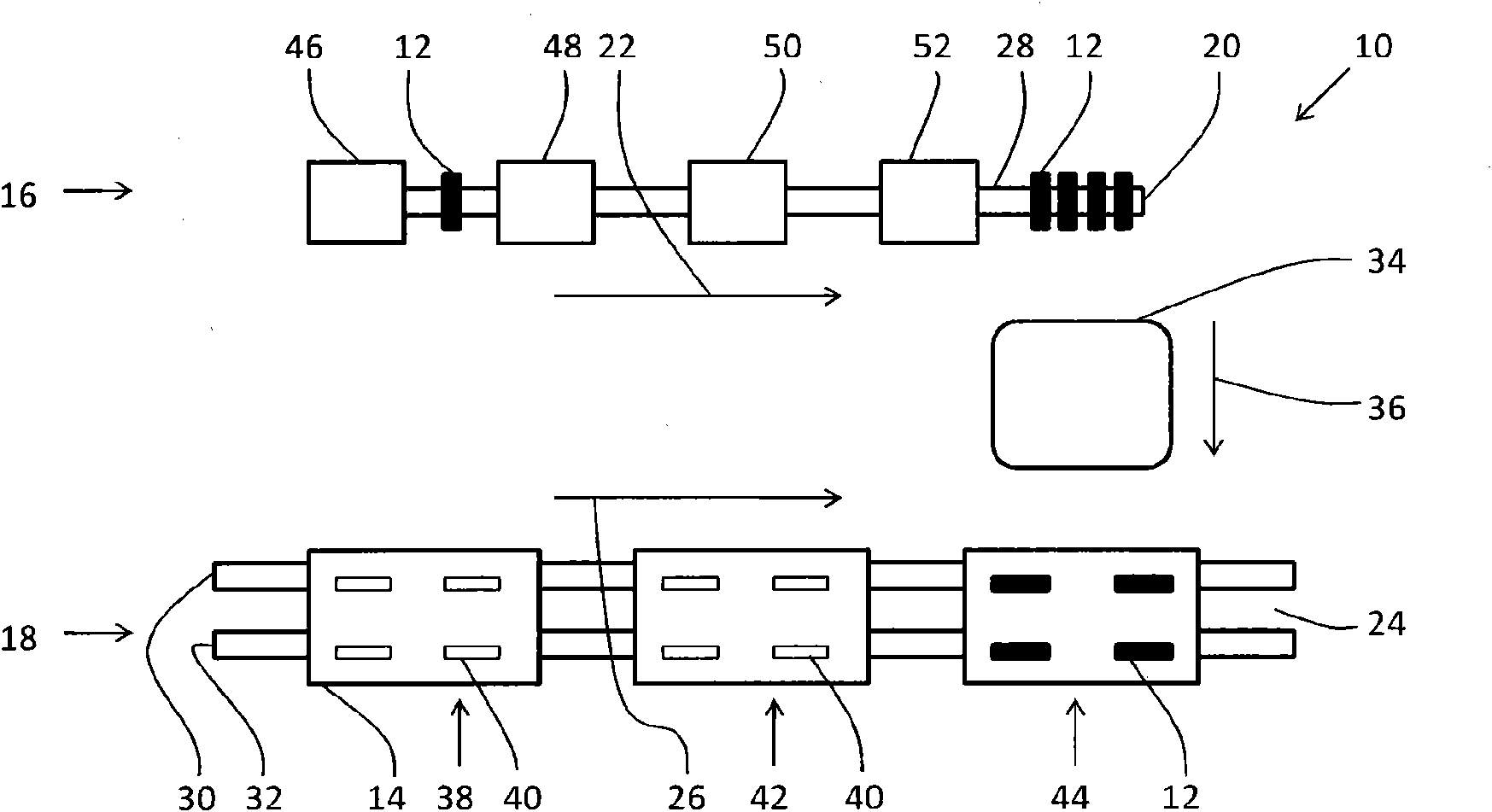

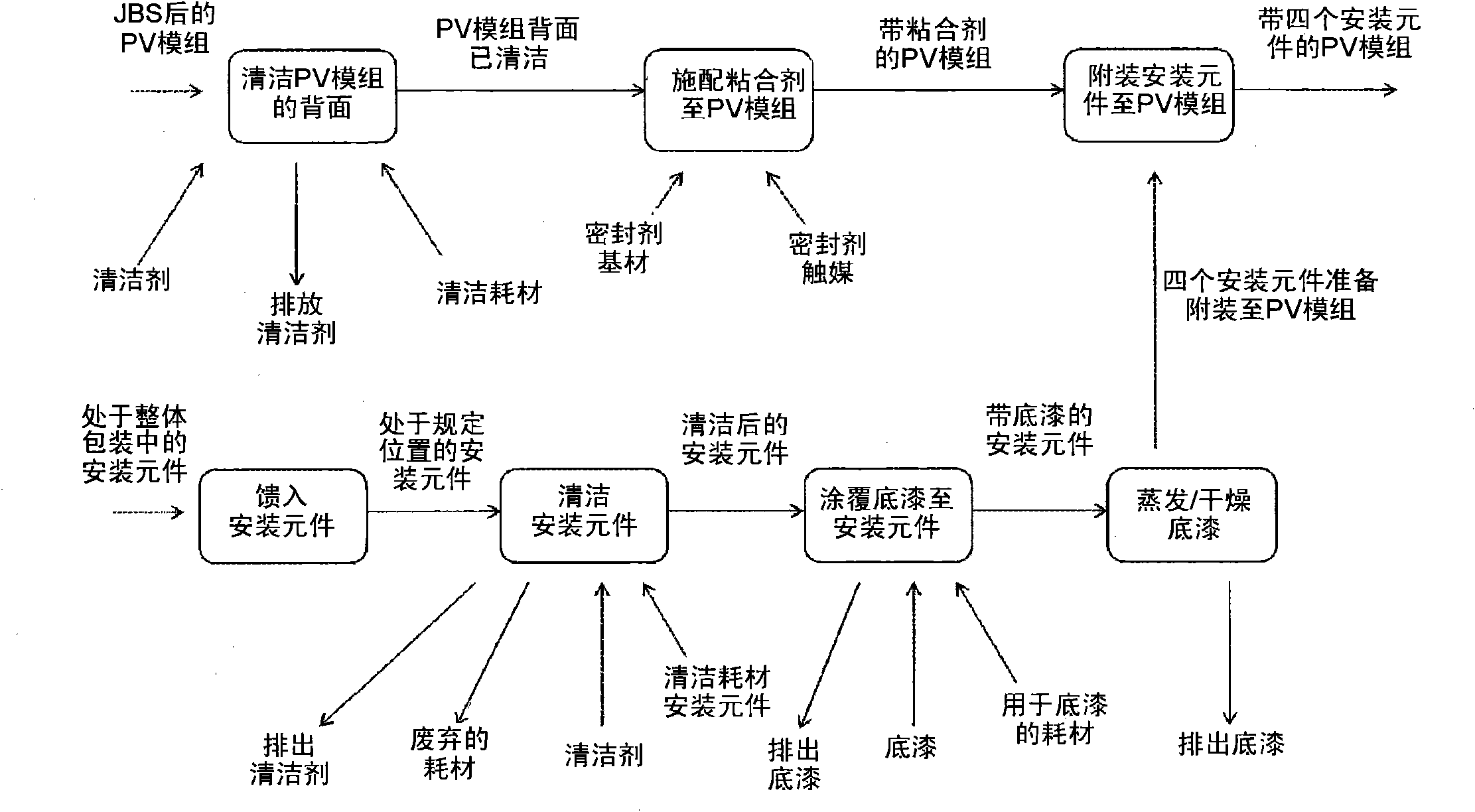

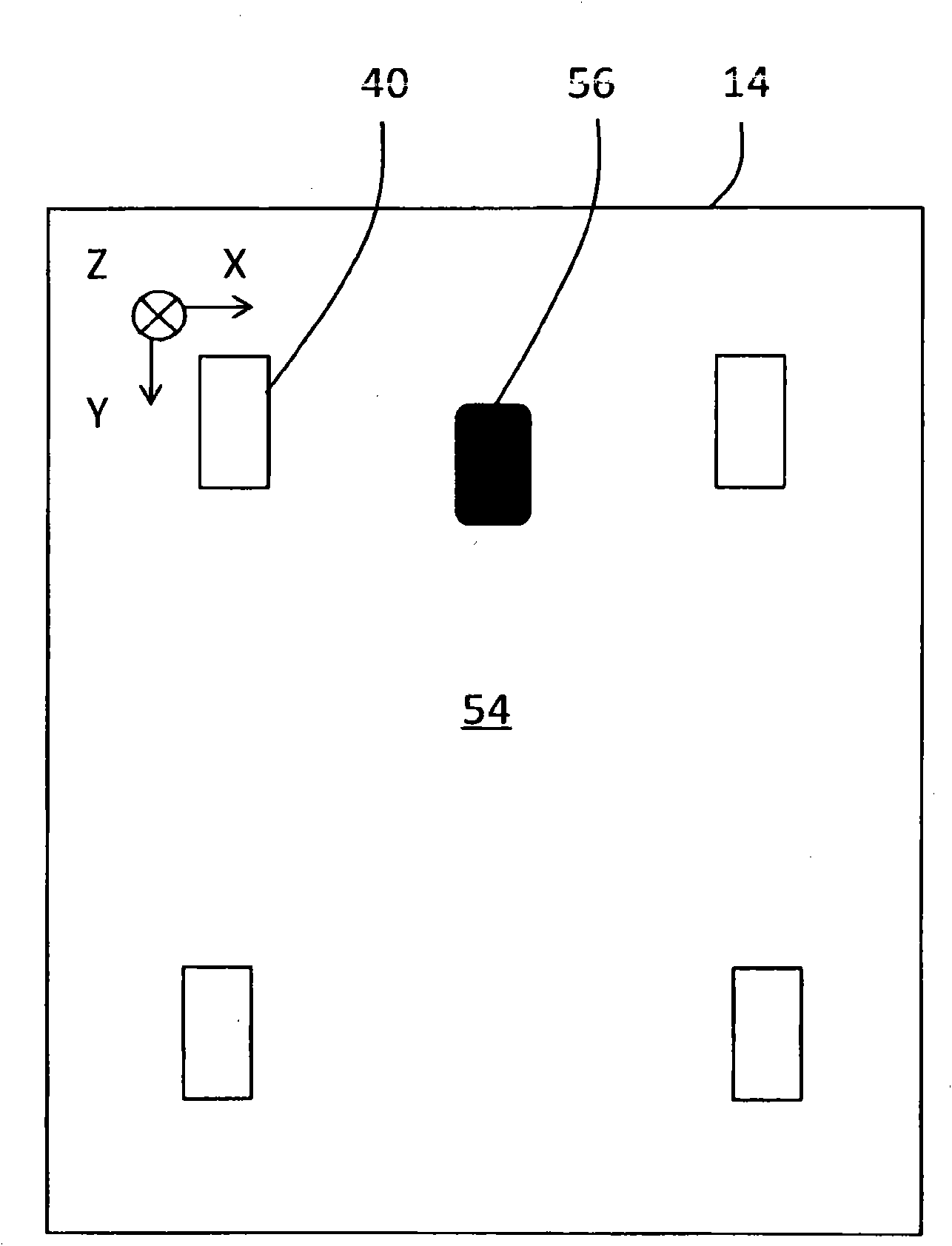

[0043] figure 1 A schematic diagram of a system 10 is shown for carrying out the method for fixing a mounting element 12 to a photovoltaic module 14 according to the present invention. The system 10 and methods performed on the system 10 improve the overall manufacturing process for forming the photovoltaic module 14 and are not limited to a particular type of photovoltaic module. The photovoltaic module 14 to which the mounting element 12 is secured can be used, for example, in building applications.

[0044] Preparation of photovoltaic modules 14 and mounting components 12 are performed in parallel in order to optimize layout, cycle time and process steps. The individual process steps are described below. It can be a semi-automatic process or a fully automatic process, preferably integrated in an industrial process. Critical process steps are controlled and the use of production materials is minimized.

[0045] The system 10 according to the present invention includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com