Conical centrifugal liquid ring dynamic seal device for super-gravity rotating bed

A high-gravity rotating bed and sealing device technology, applied in chemical/physical/physical-chemical mobile reactors, fractionation, etc., can solve problems such as poor sealing performance, serious air leakage, and inconvenient manufacturing, and achieve good structural sealing performance, The effect of convenient installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

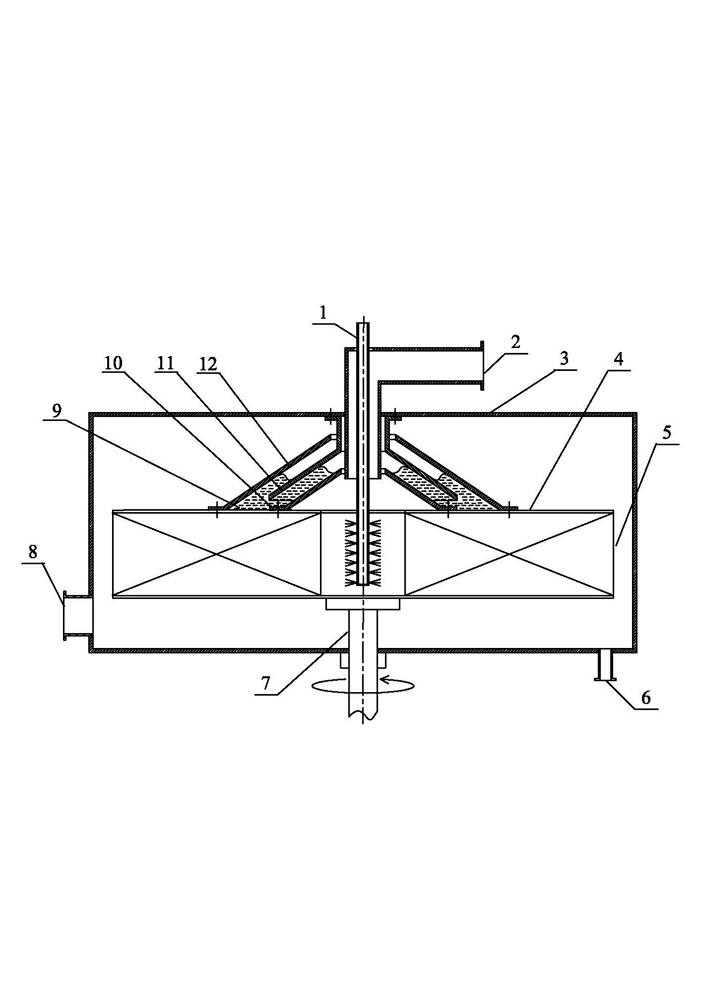

[0018] Embodiment 1: as figure 1 As shown, this conical centrifugal fluid ring dynamic sealing device for a supergravity rotating bed mainly includes a housing 3, a rotor 5, a rotating shaft 7, and a sealing device 17. The rotor 5 is fixed on the rotating shaft 7, and the housing 3 is sleeved on the rotor. 5 Externally, the upper part of the sealing device 17 is fixed on the inner wall of the upper part of the housing 3, and the lower part is fixed on the upper end surface 4 of the rotor 5, and is fixed by welding or fastening with bolts. The lower side of the housing 3 is provided with a gas phase inlet 8. The other side is provided with a liquid phase outlet 6, and the upper part of the housing 3 is provided with a liquid phase inlet 1 and a gas outlet 2.

[0019] The sealing device 17 mainly includes a movable outer conical disk 12, a static conical disk 11, a dynamic inner conical disk 10, a movable inner conical disk 10, a movable outer conical disk 12, a static conical d...

Embodiment 2

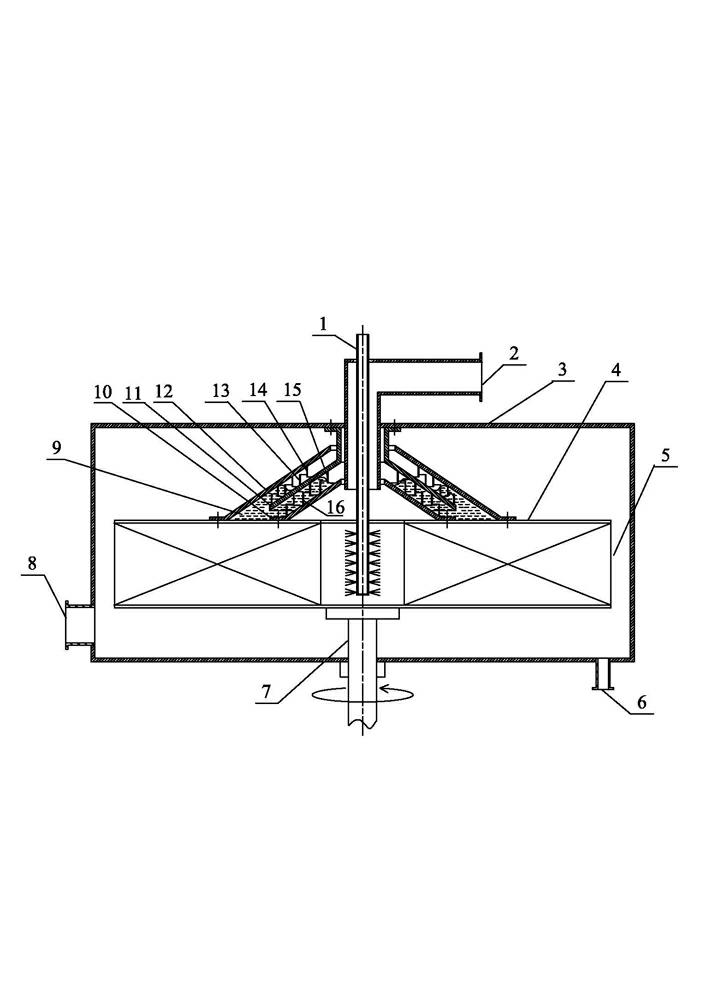

[0024] Embodiment 2: as figure 2 As shown, the difference with Embodiment 1 is that the upper and lower surfaces of the static conical ring 11 are provided with upper fins 13 and lower fins 15, and the upper surface of the movable inner conical ring 10 is provided with movable inner fins 16, and the movable inner conical ring 10 is provided with movable inner fins 16, The lower surface of the outer conical ring 12 is provided with movable outer fins 14, and the upper fins 13, lower fins 15, movable inner fins 16 and movable outer fins 14 are embedded with each other to reduce the dynamic sealing of the conical centrifugal fluid ring. Air leakage of device 17. The fins are welded vertical low circles, and the fins can be of various shapes and sizes.

Embodiment 3

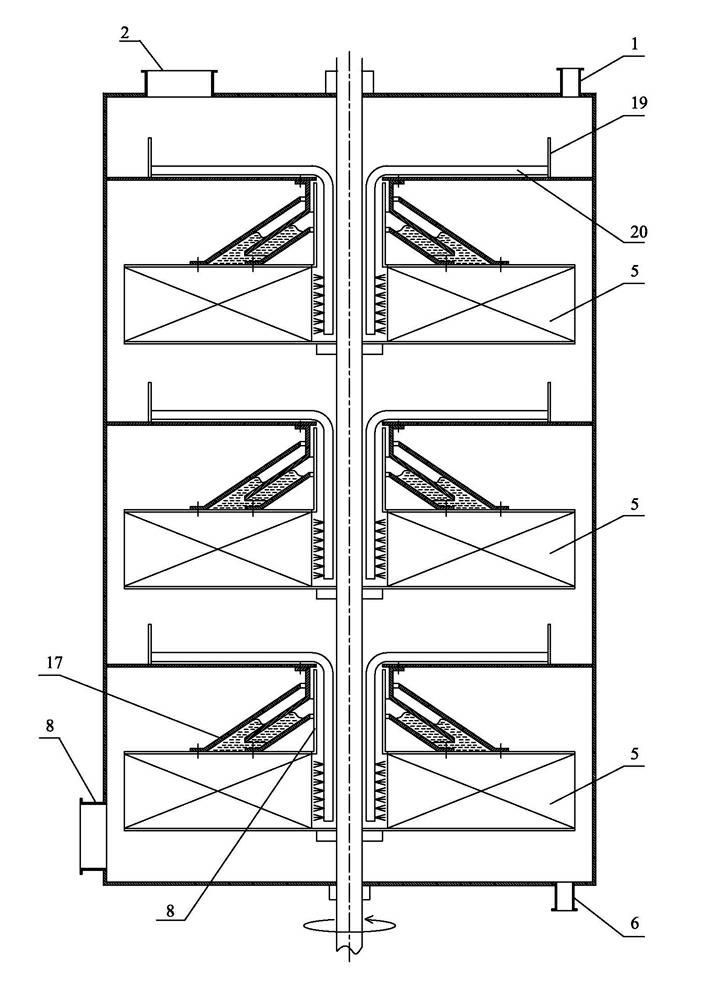

[0025] Embodiment 3: as image 3 As shown, there are multiple sets of rotors 5 and sealing devices 17 similar to Embodiment 1 or 2 connected in series on the rotating shaft 7. The center of the rotor 5 is provided with a riser pipe 18, and a drainage pipe 20 is provided near the rotating shaft 7. The upper port of the drainage pipe 20 is A cofferdam 19 is provided at the place.

[0026] Taking three rotors connected in series as an example, a sealing device 17 is installed on each of the upper end surfaces of the three rotors 5 . The gas enters the inner cavity of the rotating bed shell from the gas phase inlet 8, flows radially through the bottom rotor 5, enters the air riser 18 in the center of the rotor, flows upward, passes through the upper two rotors 5 in turn, and finally discharges from the gas outlet 2. The liquid enters from the liquid phase inlet 1, enters the uppermost rotor 5 through the cofferdam 19 and the drainage pipe 20, is thrown out under the action of cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com