Double-faced parallel symmetric silicon beam mass block structure and method for preparing same

A parallel symmetry, mass block technology, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of difficult symmetrical beam structure size, complex process, poor control symmetry, etc., to reduce cross-sensitivity, process The effect of simple, improved resistance to lateral and torsional shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

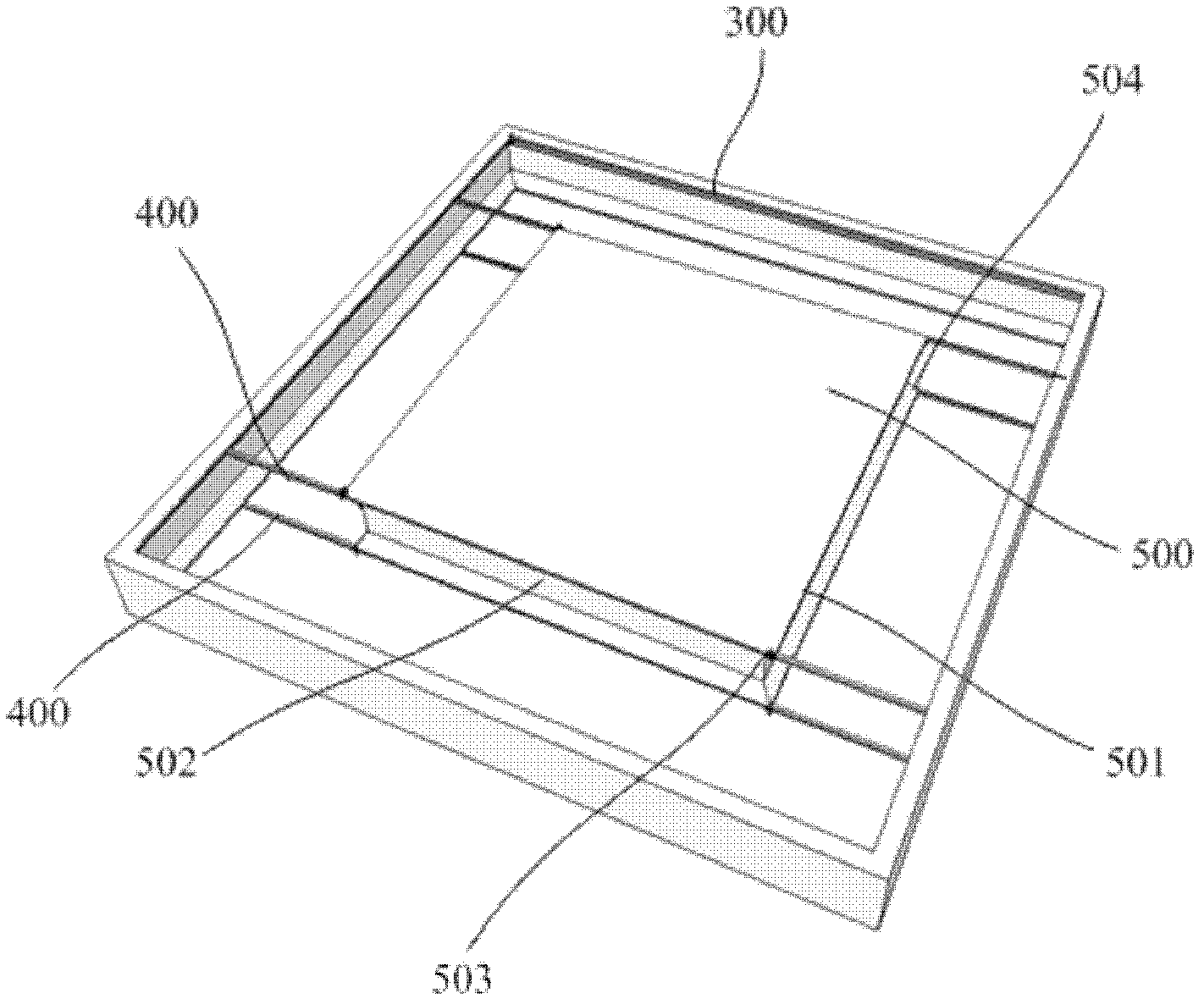

[0066] Such as figure 1 As shown, the present invention provides a double-sided parallel symmetrical silicon beam-mass structure, comprising:

[0067] A support frame 300 , a mass block 500 and a plurality of cantilever beams 400 .

[0068] The support frame 300 is arranged in the acceleration sensor, and its frame body is in a rectangular structure. The mass block 500 conforms to the frame to form a rectangular cubic structure and is arranged in the support frame 300 , and each side of the mass block 500 has trapezoidal grooves 502 .

[0069] The cross-section of the cantilever beam 400 is pentagonal, the cantilever beam 400 extends along the horizontal edge 501 of the mass block 500 and is connected to the support frame 300, each of the cantilever beams 400 is symmetrically distributed on the The four top corners 503 and four bottom corners 504 of the mass block 500, and the cantilever beam 400 distributed at one top corner 503 of the mass block 500 and the cantilever beam...

Embodiment 2

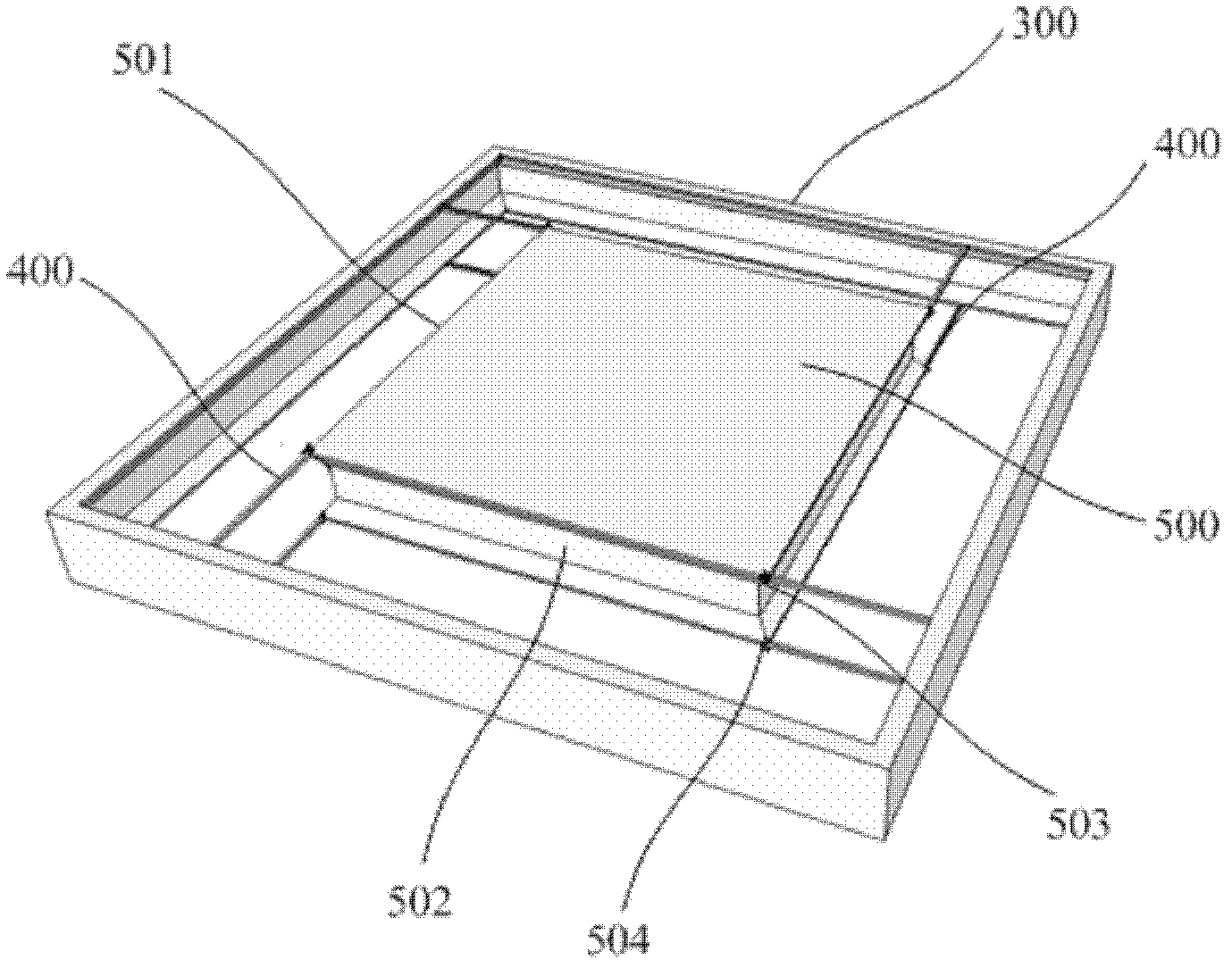

[0074] Such as figure 2 As shown, the present invention provides a double-sided parallel symmetrical silicon beam-mass structure, the difference between this structure and the structure in Embodiment 1 is:

[0075] A pair of parallel cantilever beams 400 are respectively distributed on the top corners 503 of the mass block 500 and the corresponding bottom corners 504, and a pair of cantilever beams 400 extend from each horizontal edge 501 of each side of the mass block 500. , there are 8 cantilever beams 400 in this case, which are parallel and symmetrically distributed on the upper and lower surfaces of the proof mass 500 .

[0076] Other structures are the same as those in Embodiment 1, and will not be repeated in this embodiment.

Embodiment 3

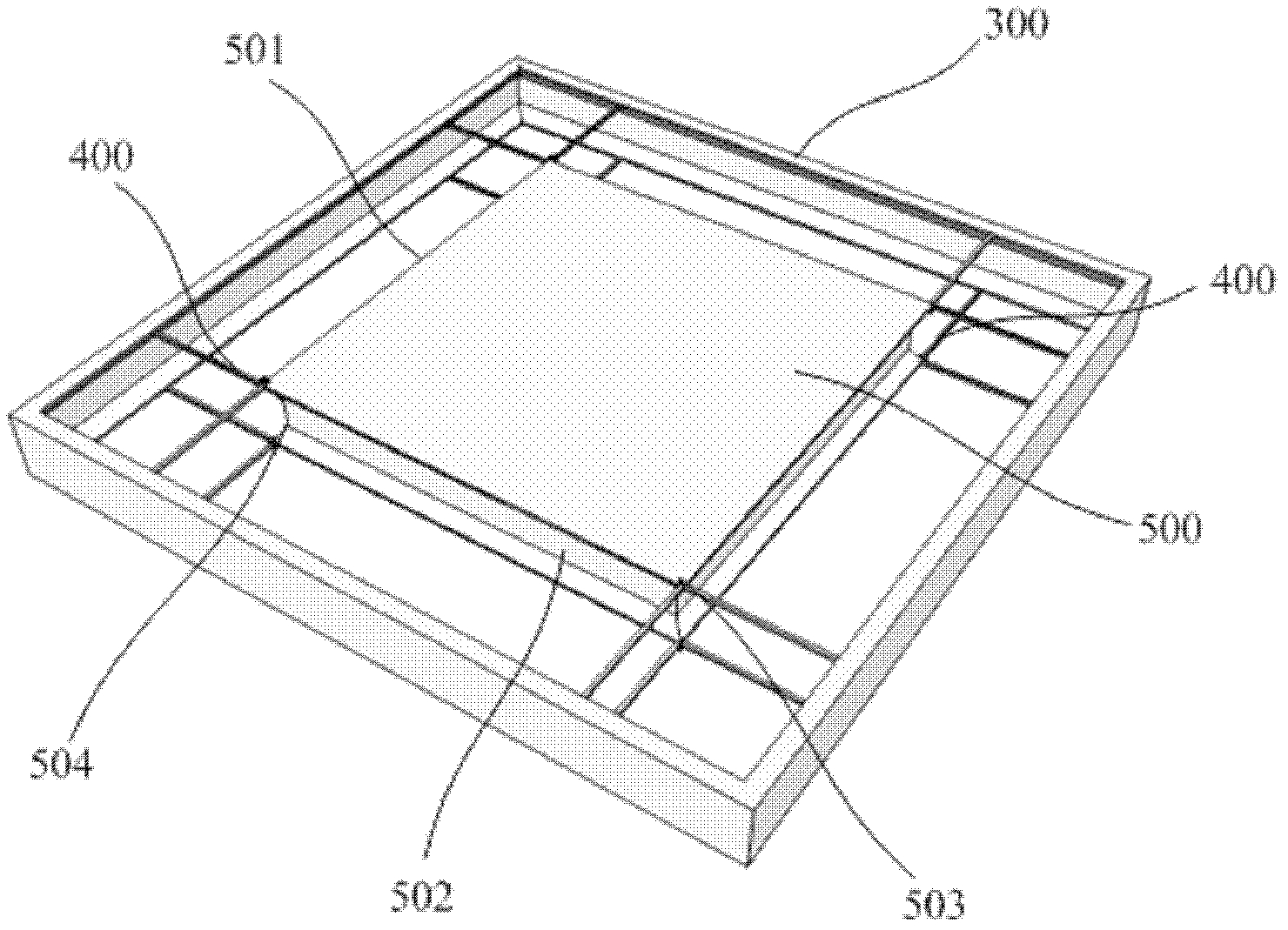

[0078] Such as image 3 As shown, the present invention provides a double-sided parallel symmetrical silicon beam-mass structure, the difference between this structure and the structure in Embodiment 1 is:

[0079] Each top corner 503 of the mass block 500 and its corresponding bottom corner 504 are respectively intersected with two pairs of parallel cantilever beams 400 , and the horizontal edge 501 of each side of the mass block 500 extends with two For the cantilever beams 400 , there are 16 cantilever beams 400 in this case, which are parallel and symmetrically distributed on the upper and lower surfaces of the proof mass 500 .

[0080] Other structures are the same as those in Embodiment 1, and will not be repeated in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com