Oil-water-solid separation device for kitchen wastes

A technology of waste oil and oil-water separator, which is applied in the directions of liquid separation, separation method, grease/oily substance/floating matter removal device, etc., can solve the problem of unsatisfactory effect, deterioration and smell of kitchen waste, and consumption of a lot of energy. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

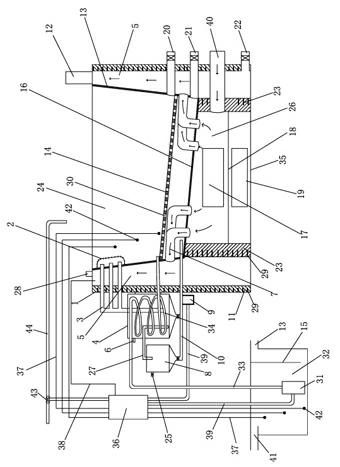

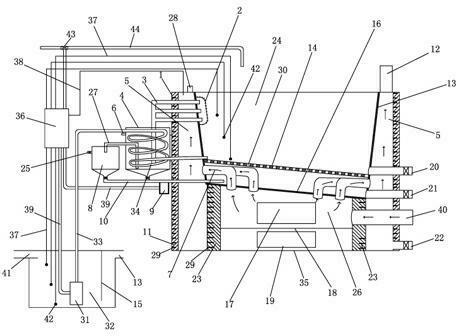

[0025] The present invention will be further described below in conjunction with accompanying drawing of description:

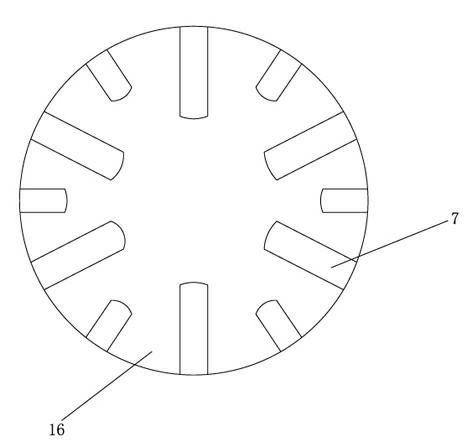

[0026] as attached figure 1 As shown, the kitchen waste oil-water-solid separation device of the present invention includes a heating furnace 35, an oil-water separator 4, a discharge port 20, a water outlet 21, a dust discharge port 22, an electric controller 36, and a grease trap 32. The heating furnace 35 is composed of a body of furnace 1 and a feed liquid container 24, the cavity between the body of furnace 1 and the feed liquid container 24 is a hot smoke chamber 5, and a chimney 12 is arranged on the top of the heat smoke chamber 5. The top of the liquid container 24 is provided with a spare water pipe 44, its bottom surface is a slope bottom 16, and its lower part is a high-temperature smoke chamber 26. A refractory support 23 is arranged around the high-temperature smoke chamber 26, and the middle part of the outer side is respectively provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com