Preparation method of trioxymethylene

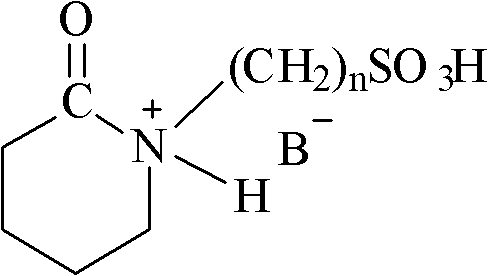

A technology of paraformaldehyde and formaldehyde aqueous solution, which is applied in the direction of organic chemistry, can solve the problems of complex ionic liquid synthesis process and high cost, and achieve the effects of short reaction time, low equipment corrosion and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

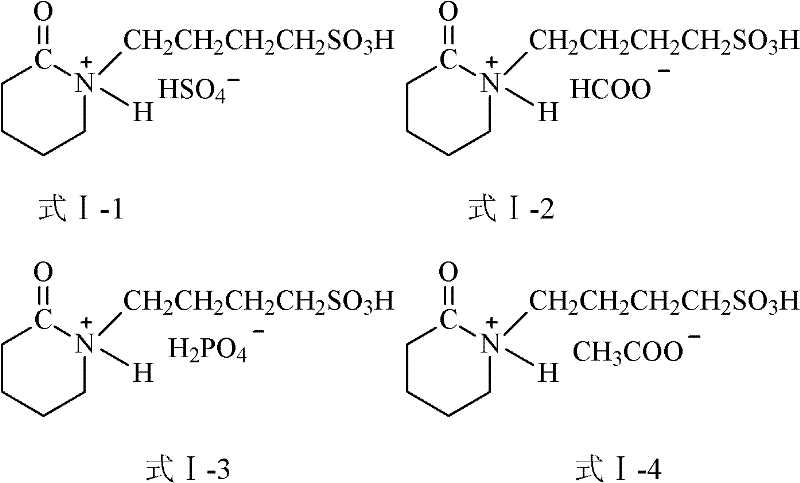

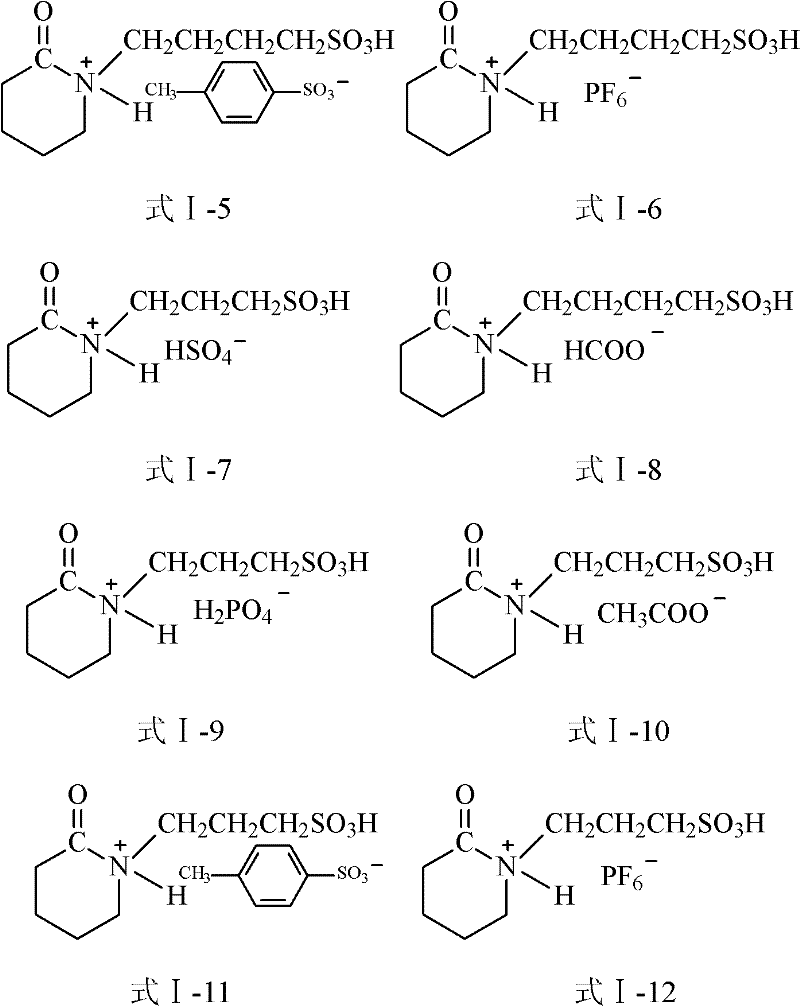

[0030] The preparation of embodiment 1, paraformaldehyde

[0031] Add 60g of formaldehyde aqueous solution (formaldehyde content 60.0%) in reaction vessel, then add 2% (mass ratio with formaldehyde aqueous solution) Brφnsted acidic ionic liquid shown in formula I-1; Heat to 100 ℃, stirring reaction 1.5h, Through gas chromatographic analysis, the content of paraformaldehyde in the synthesis liquid is 2.44%, and the content of formic acid (in terms of acid value) is 3328ppm.

Embodiment 2

[0032] The preparation of embodiment 2, paraformaldehyde

[0033] Others are the same as in Example 1, using the Brφnsted acidic ionic liquid shown in formula I-2 as a catalyst, and the consumption is 5.0% (mass ratio with formaldehyde solution) of formaldehyde solution (formaldehyde content 48.0%); heated to 95 ° C, stirred for 1.5 h, the content of paraformaldehyde in the synthesis liquid is 1.35%, and the content of formic acid is 2433ppm.

Embodiment 3

[0034] The preparation of embodiment 3, paraformaldehyde

[0035] Others are the same as in Example 1, using the Brφnsted acidic ionic liquid shown in formula I-3 as a catalyst, and the dosage is 3.0% (mass ratio to the formaldehyde solution) of the formaldehyde solution (formaldehyde content 68.0%), heated to 100° C., and stirred for 2 hours , the content of paraformaldehyde in the synthetic liquid is 1.43%, and the content of formic acid is 2547ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com