Water-in water type colorful thermal insulation coating and preparation method thereof

A thermal insulation coating, water-based technology, applied in the field of architectural coatings, to achieve excellent decorative performance and thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

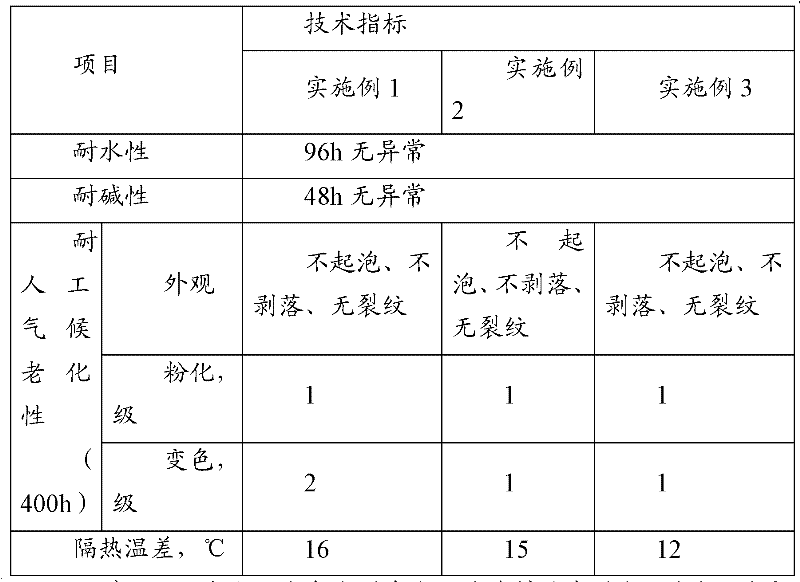

Embodiment 1

[0032] Dispersed phase (white): Add 32.4 parts of water, 0.1 part of sodium pyrophosphate, 2.0 parts of lithium magnesium silicate, 0.2 parts of dispersant, and 0.3 parts of defoamer to the dispersion tank in turn, stir at 500 rpm, and add each component disperse and stir for 3 minutes; increase the speed to 1200rpm, add 16 parts of pigments and fillers and 0 parts of heat-insulating pigments, and disperse for 15 minutes; adjust the speed to 600rpm, add 3 parts of film-forming aids, and slowly add 46 parts of silicon acrylic after stirring for 5 minutes Emulsion, stir well and set aside;

[0033] Dispersed phase (black): Add 26 parts of water, 0.1 part of sodium pyrophosphate, 2.2 parts of lithium magnesium silicate, 0.4 parts of lithium magnesium silicate, and 0.3 parts of defoamer to the dispersion tank in turn, and stir at 600 rpm. The components were dispersed and stirred for 3 minutes; the speed was increased to 1500 rpm, 13 parts of pigments and fillers and 5 parts of bl...

Embodiment 2

[0038] Dispersed phase (white), dispersed phase (black) and dispersed phase (yellow) are prepared by the method of Example 1, only the brown heat insulating pigment is replaced by a yellow heat insulating pigment; the continuous phase is also prepared by the method of Example 1;

[0039] Finished product: Add 46 parts of the continuous phase to the dispersion tank, stir at a low speed, slowly add 4 parts of the dispersed phase (white), 2 parts of the dispersed phase (black), and 26 parts of the dispersed phase (brown) during the stirring process, until the particle diameter reaches the requirement Finally, add 18 parts of silicone acrylic emulsion, and finally add 0.2 parts of pH adjuster and 3.8 parts of thickener aqueous solution to adjust to a suitable viscosity.

Embodiment 3

[0041] Dispersed phase (blue), dispersed phase (brown) and dispersed phase (yellow) are prepared by the method of Example 1, only need to replace the brown heat insulating pigment with brown heat insulating pigment, blue heat insulating pigment and yellow heat insulating pigment ; Continuous phase also adopts the method preparation of embodiment 1;

[0042] Finished product: Add 46 parts of the continuous phase to the dispersion tank, stir at a low speed, slowly add 5 parts of the dispersed phase (blue), 21 parts of the dispersed phase (brown), and 6 parts of the dispersed phase (yellow) during the stirring process until the particle diameter reaches After request, add 20 parts of silicone acrylic emulsion, and finally add 0.2 parts of pH adjuster and 3.8 parts of thickener aqueous solution to adjust to a suitable viscosity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com