Entrained flow gasifier and slag hole brick thereof

A technology of gasification furnace and entrained flow bed, which is applied in the field of coal gasification, can solve the problems affecting the stable long-term full-load operation of the gasification device, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

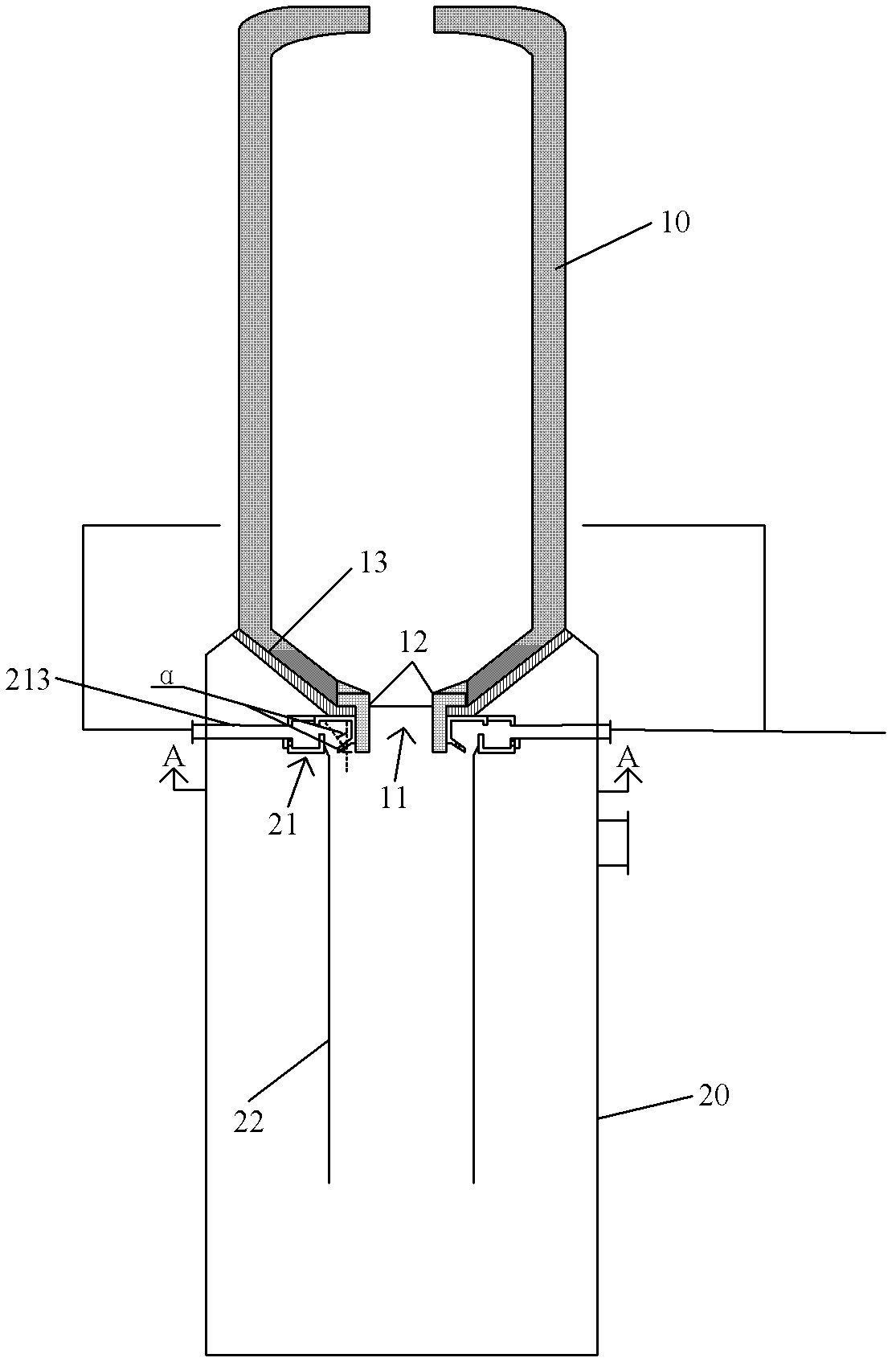

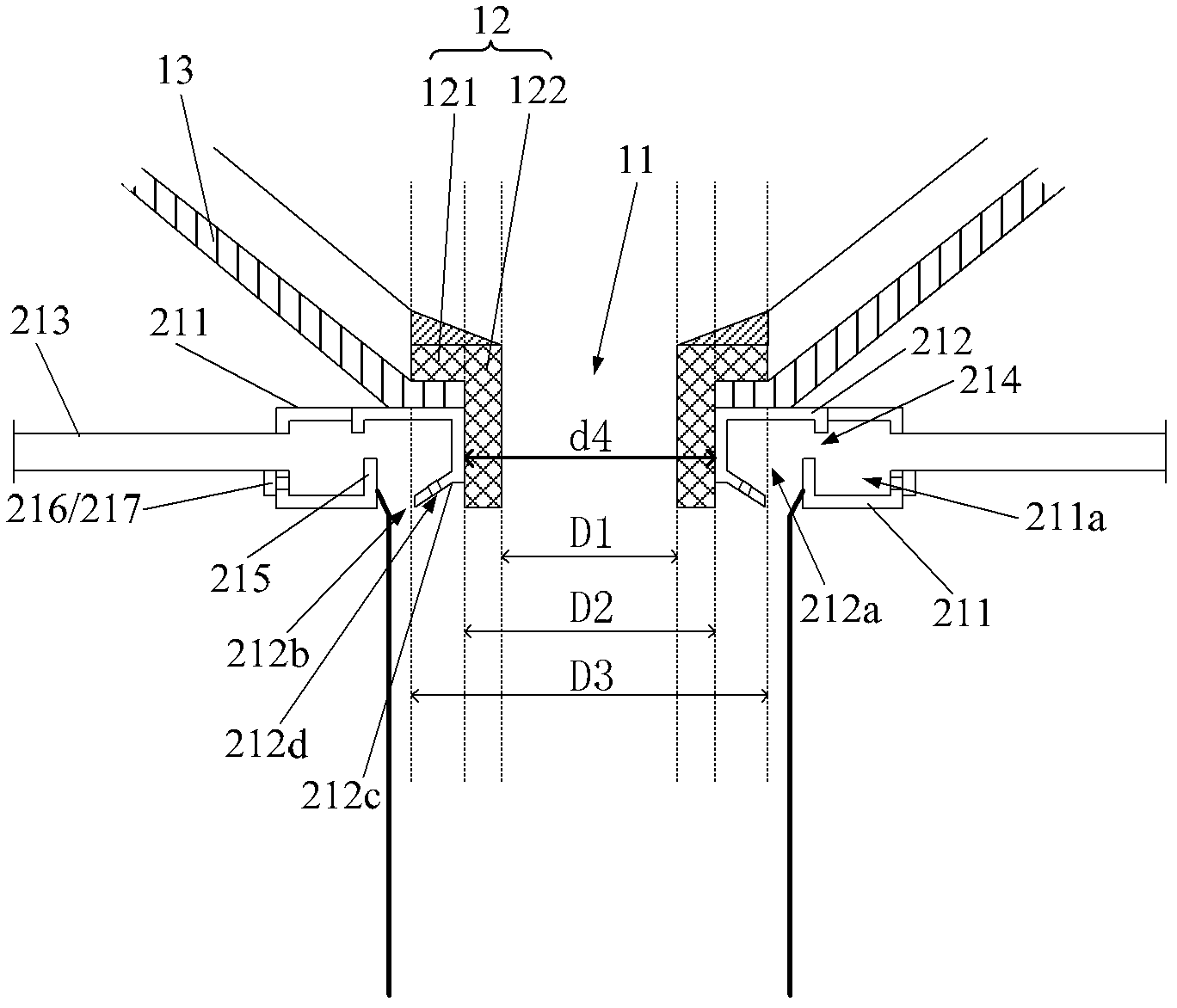

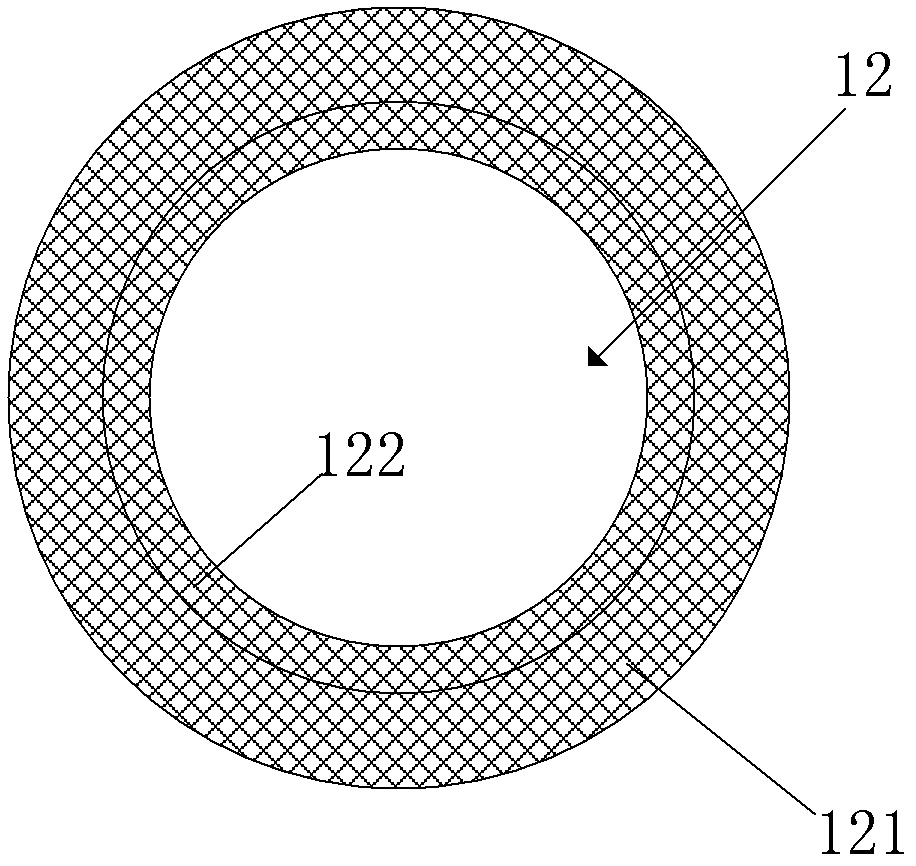

[0044] figure 1 and figure 2 A schematic structural view of the gasification gasification furnace and its slag brick according to the present invention is shown. Such as figure 1 As shown, the gasifier includes a combustion chamber 10 and a quenching chamber 20 positioned below the combustion chamber 10. The top of the combustion chamber 10 is provided with a composite burner (not shown in the figure), and the bottom is provided with a slag port 11. The quenching chamber 20 is provided with a quenching ring 21 located below the slag mouth 11 and a downcomer 22 below the quenching ring 21. The slag mouth 11 is provided with a slag mouth brick 12, and the slag mouth brick 12 includes a cone supported on the slag mouth 11. The annular slag mouth po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com