Splicing method for complex jigsaw unit type curtain wall unit plate block

A curtain wall unit, unitized technology, applied in the processing of walls, building materials, building components, etc., can solve the problems of uneven seam width, low splicing efficiency, easy welding, etc., to reduce production costs, high splicing efficiency, Strong stitching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

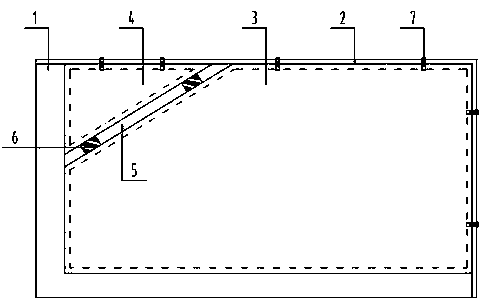

[0034] The manufacturing process of complex jigsaw unit curtain wall is usually, according to the overall design of the curtain wall facade jigsaw puzzle and the actual situation on site, use computer to aid design and calculation, carry out unit division, skeleton layout and unit plate unified numbering; draw the unit plate processing diagram, According to the processing drawing, the jigsaw blocks are processed and spliced to form firmly connected regular unit blocks; finally, the on-site installation of the curtain wall is carried out.

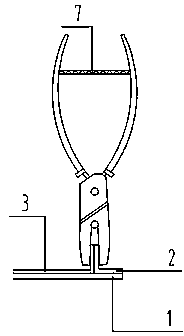

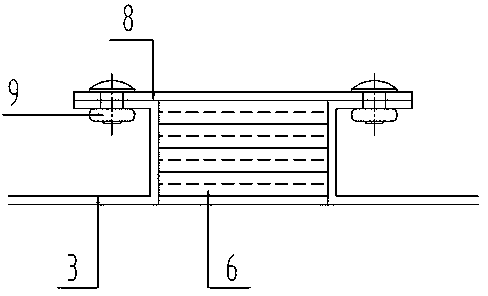

[0035] In order to achieve the overall effect of the complex jigsaw perforated aluminum veneer curtain wall design, the joints on the elevation should be straight and have the same width. Therefore, measures must be taken during the production of unit panels, especially in the splicing of unit panels. The stitching lines are straight and the seam width is the same; each puzzle piece is firmly spliced.

[0036] The production and shaping of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com