Method for correcting test deviation of relative reduction rate of pellet

A correction method and pelletizing technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as waste of test materials, impact on test accuracy, loss, etc., and achieve the effect of saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

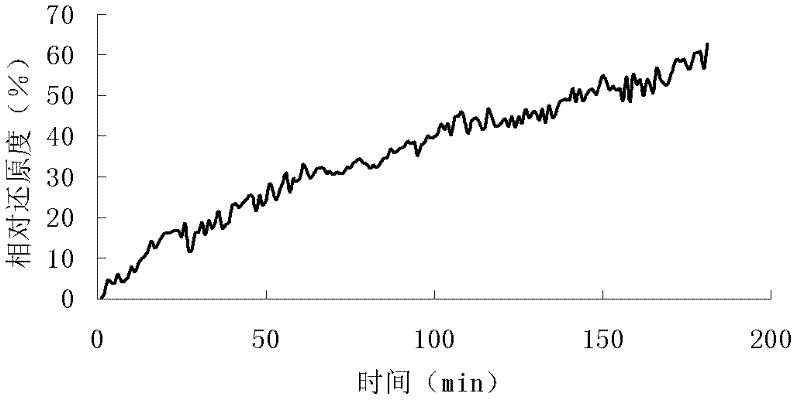

[0020] Embodiment: install and use MATLAB software on the computer, for figure 1 For the noisy one-dimensional signal shown, the noise reduction steps are:

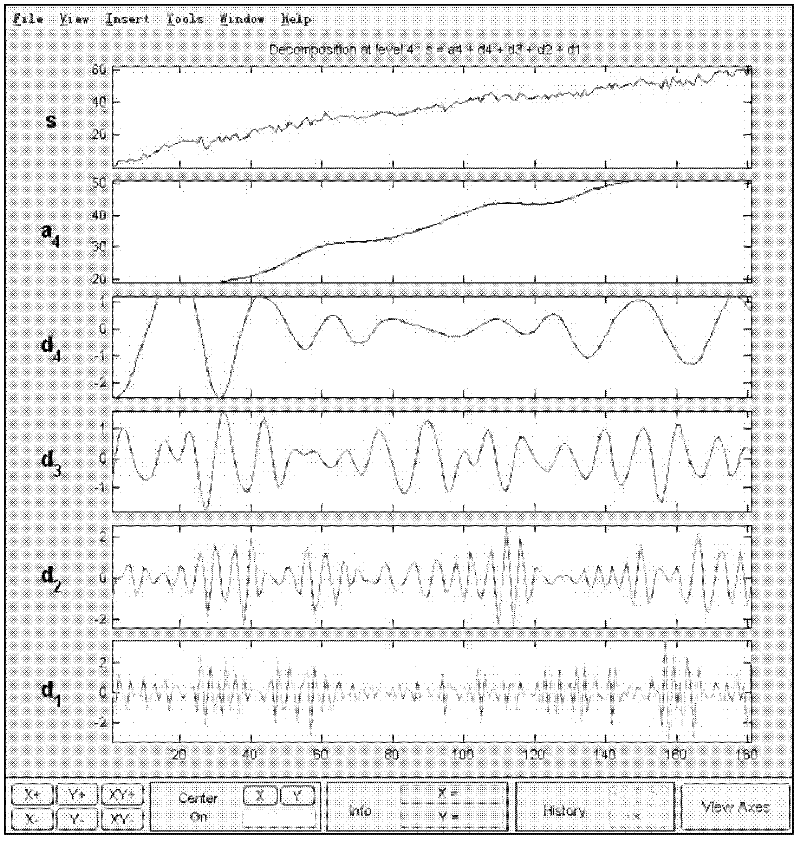

[0021] 1) Select Daubechies (dbN) wavelet, select one-dimensional discrete wavelet transform in Matlab's wavelet toolbox, import data, select db10, and perform 4-layer decomposition, as follows figure 2 The decomposition results are shown. It can be seen that compared with the original curve (s), there is still a curve (a 4 ) is relatively smooth.

[0022] 2) Restoration result correction

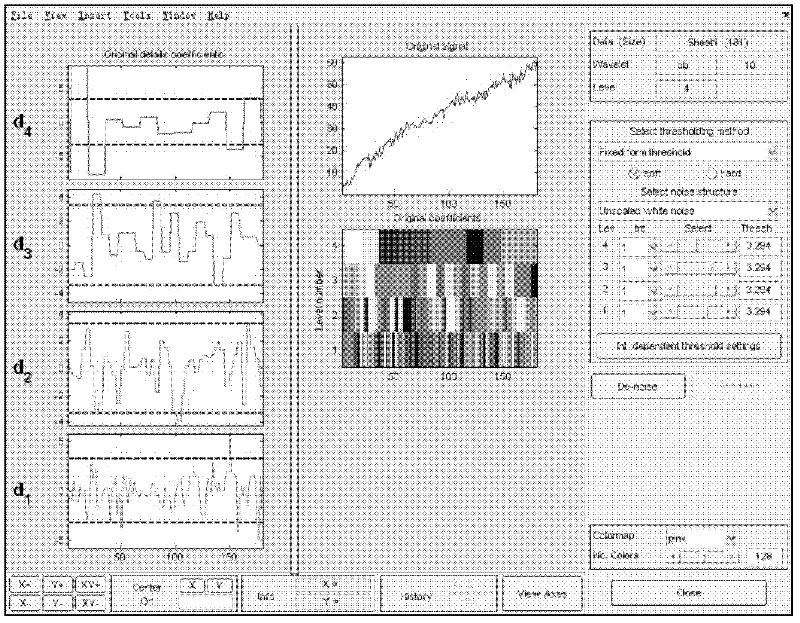

[0023] On the basis of the above db wavelet decomposition, denoising (De-noise) is performed to obtain image 3 result. for the separated high frequency noise curve at d 1 to d 4 Set the threshold, 90% of the high-frequency signal is included in the range of the lower threshold and the upper threshold, and then perform one-dimensional wavelet reconstruction according to the bottom low-frequency coefficients and high-level high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com