Method and device for gas cleaning

A gas cleaning and equipment technology, applied in mechanical equipment, chemical instruments and methods, solid separation, etc., can solve problems such as difficulty in cleaning electrostatic dust filters, and achieve the effects of low power consumption, easy implementation, and high charge density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

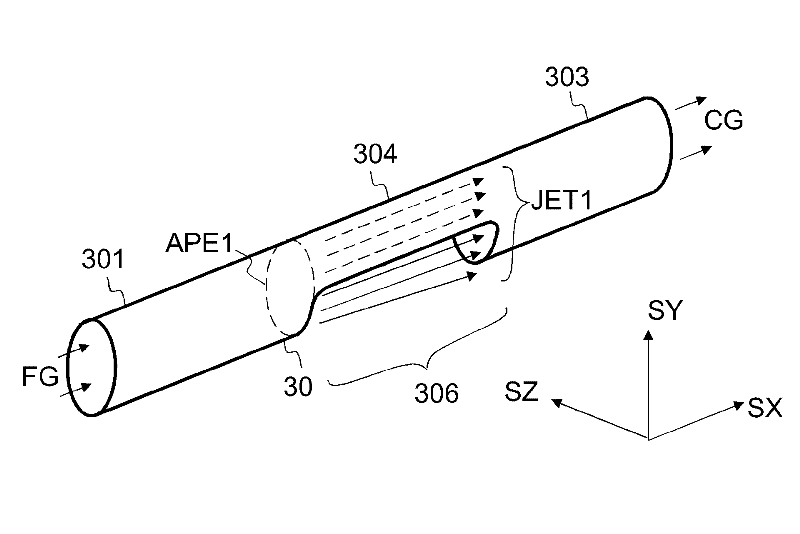

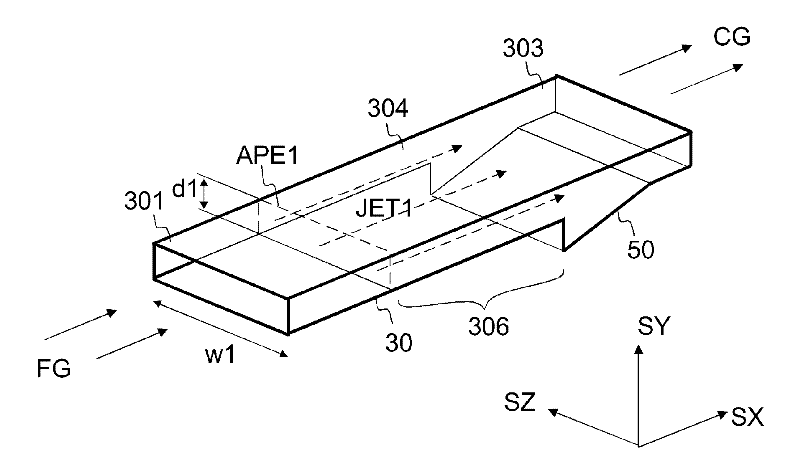

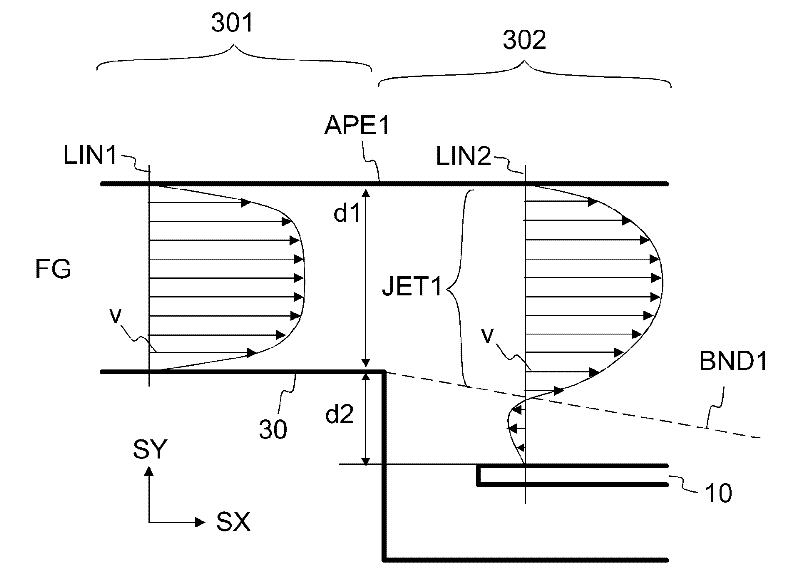

[0049] Referring to FIG. 1 , a gas cleaning apparatus 500 may include a particle charging unit 150 , a flow guiding structure 30 , and a particle collector 10 .

[0050] The particulate-laden gas FG may be introduced into the gas cleaning device 500 via an intake conduit 301 .

[0051] The particle charging unit 150 is configured to form charged particles P1 by charging the neutral particles P0 of the particle-laden airflow FG. The particulate-laden gas FG may eg be flue gas from a combustion process.

[0052] The particles P0 may eg be solid or liquid particles. The diameter of the particle P0 may for example be in the range of 5 nm to 500 nm.

[0053] The charging unit 150 may include an ion source 100 and an intake duct 301 . The ion source 100 is arranged to provide a flow of ionized gas IG. The ionized gas IG includes ions J1, such as Figure 1a shown by the black dots.

[0054] Ionized gas IG may be introduced into intake conduit 301 via nozzle 130 . The substantiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com