Forming method for preparing environment friendly composite material by jean fabrics

A denim fabric and composite material technology, applied in the field of composite material manufacturing, can solve the problems of environmental pollution, low specific gravity, resource waste, etc., and achieve the effects of good wear resistance, low scratch resistance, good impact resistance and shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] Production of waste denim fabric polypropylene resin composite film

[0037] 1. The waste denim fabric 1 is washed, sterilized, dried, flattened, and then cut. (Length and width are both 20cm)

[0038] 2. Press the polypropylene resin masterbatch at a temperature of 180 degrees Celsius and a pressure of 4 MPa for 2 minutes to form a film with a thickness of about 0.2 mm.

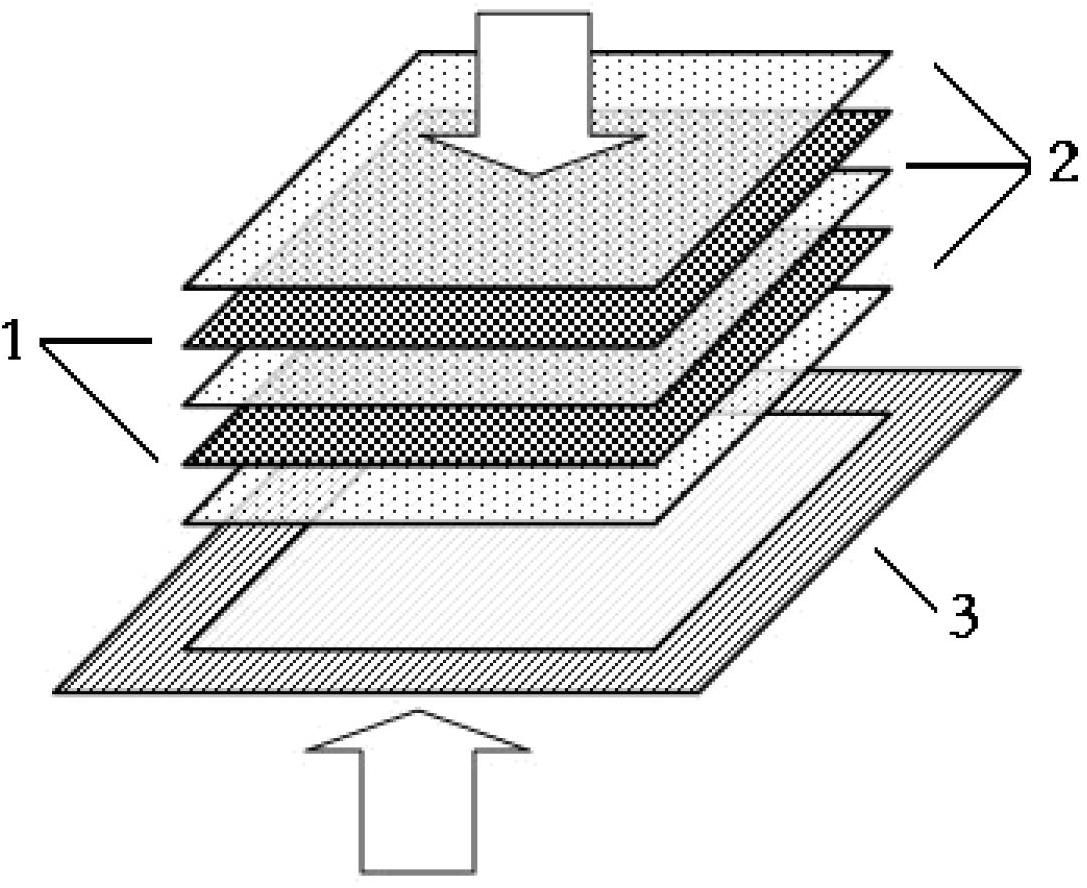

[0039] 3. Place the finished 2-layer denim fabric 1 and the 3-layer polypropylene resin film alternately, and place the polyimide film on the upper and lower sides of the denim fabric and the polypropylene resin film.

[0040] 4. Put all the above-prepared materials into a flat plate hot press, preheat at 195 degrees Celsius for 3 minutes, and after the resin is melted, press it for 3 minutes at a pressure of 4 MPa.

[0041] 5. Put the hot-pressed composite material on a hot-pressing machine with a temperature of about 40 degrees Celsius and cold-press for 3 minutes under a pressure of 3 MPa. Afte...

example 2

[0043] Preparation of Thermoplastic Composites from Waste Denim Fabrics in Curved Shape

[0044] 1. The waste denim fabric 1 is washed, sterilized, dried, flattened, and then cut. (Length and width are both 20cm)

[0045] 2. Press the polypropylene resin masterbatch at a temperature of 180 degrees Celsius and a pressure of 4 MPa for 2 minutes to form a film with a thickness of about 0.2 mm.

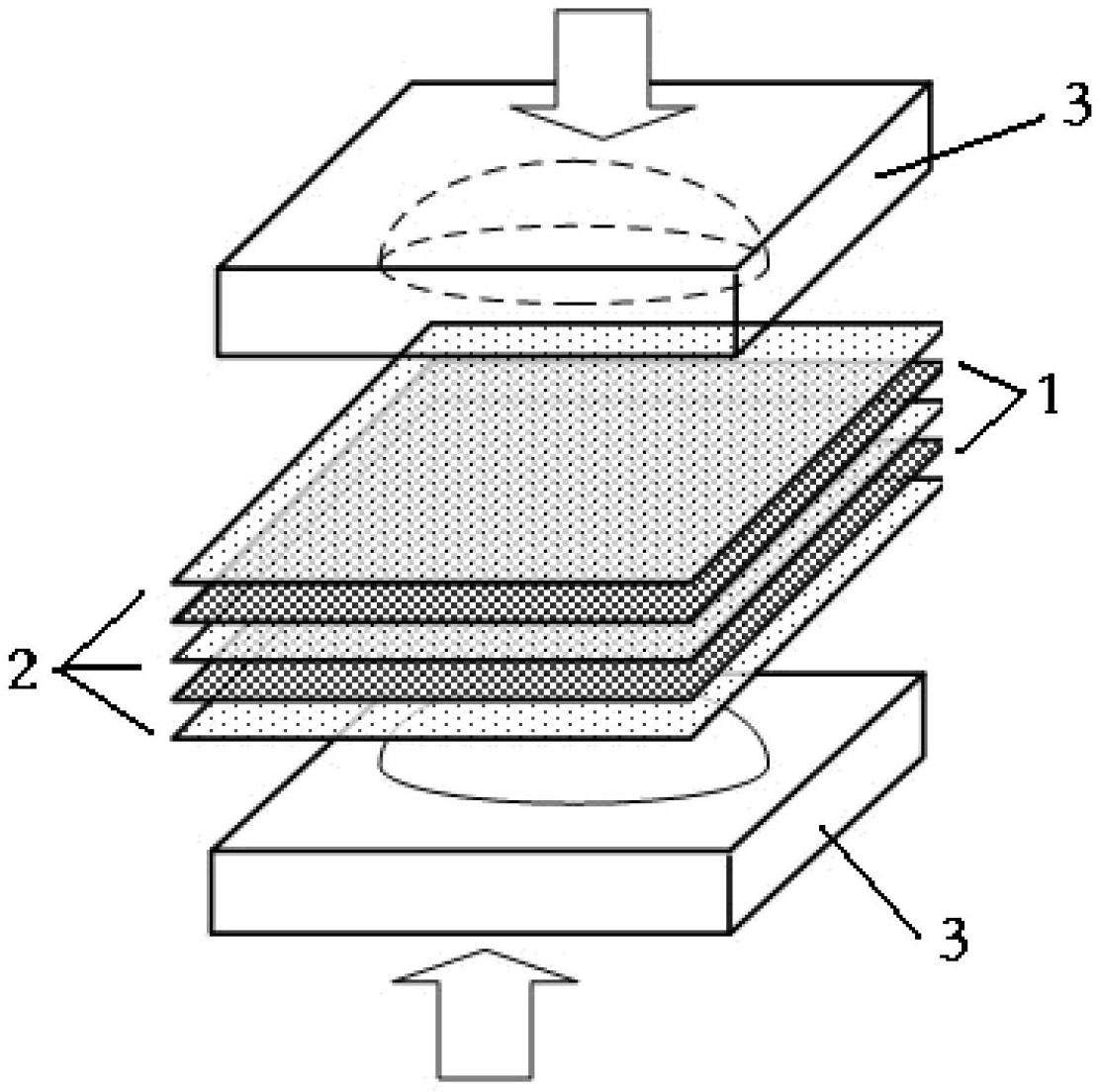

[0046] 3. Prepare a metal mold 3 of a corresponding shape, place the finished denim fabric and the polypropylene resin film alternately, and place the polyimide film on the upper and lower sides of the denim fabric and the polypropylene resin film.

[0047] 4. Put all the above-prepared materials on a flat-plate hot press, preheat for 3-5 minutes at a temperature of 195 degrees Celsius, and press for 3 minutes at a pressure of 4 MPa after the resin is melted. The hot pressing time can be appropriately increased according to the number of layers of the denim fabric.

[0048] 5. Put the ...

example 3

[0050] Preparation of waste denim fabric thermoplastic sandwich composites

[0051] 1. The waste denim fabric 1 is washed, sterilized, dried, flattened, and then cut. (Length and width are both 20cm)

[0052] 2. Press the polypropylene resin masterbatch at a temperature of 180 degrees Celsius and a pressure of 4 MPa for 2 minutes to form a film with a thickness of about 0.2 mm.

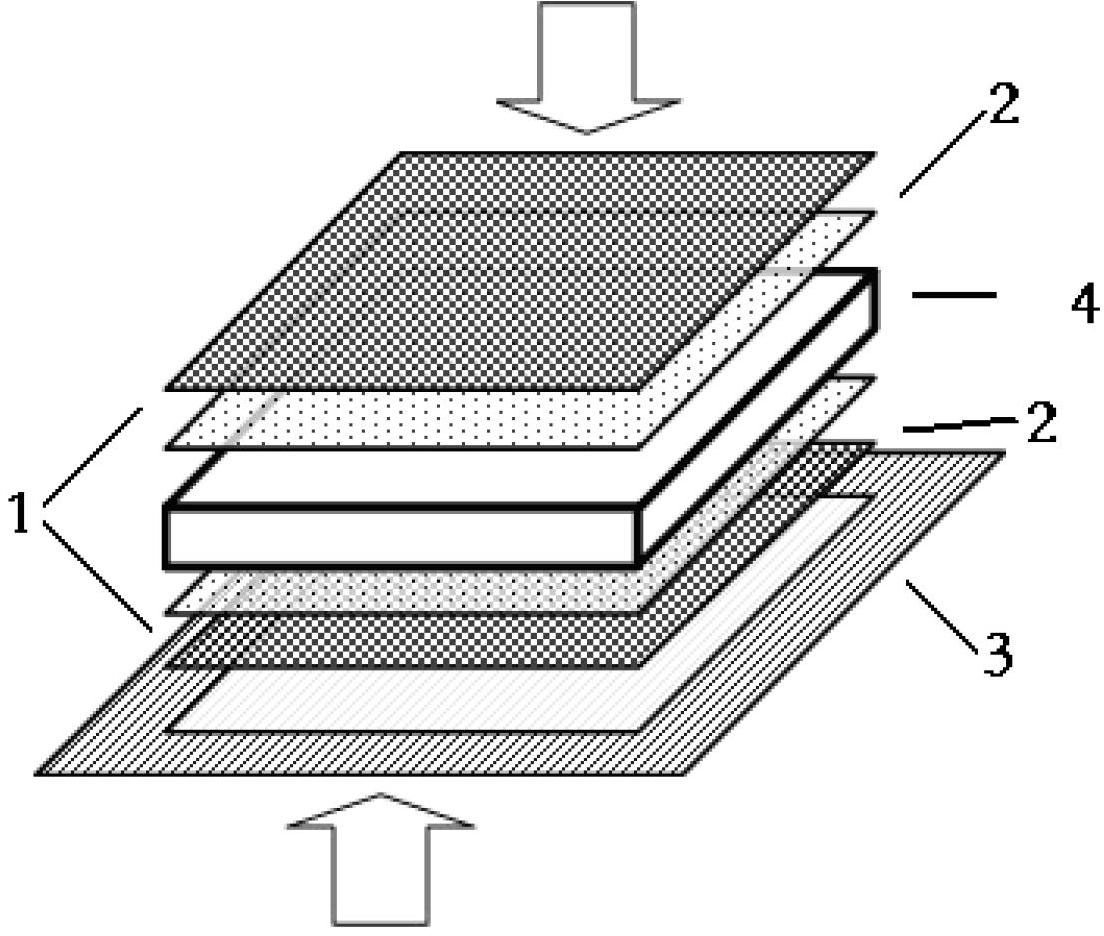

[0053] 3. A board with a thickness of 2cm and a length and width of 20cm is used as the interlayer material. The selection requirements of the interlayer material are as follows: it can withstand a high temperature of about 200 degrees Celsius and a pressure of about 2 MPa.

[0054] 4. Place the thermoplastic resin film between the interlayer material and the waste denim fabric (such as image 3 shown), place the polyimide film on the upper and lower sides of the denim fabric and polypropylene resin film.

[0055] 5. Then put it on a flat plate hot press, preheat for 3-5 minutes at a temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com