Color filter with polarization ability and manufacturing method thereof

A technology for a color filter and a manufacturing method, which are applied in the direction of a filter, a polarizing element, a photoengraving process of a patterned surface, etc., can solve the problems of manpower and material resources, cumbersome process, time-consuming and the like, so as to save process time, Guaranteed display effect and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

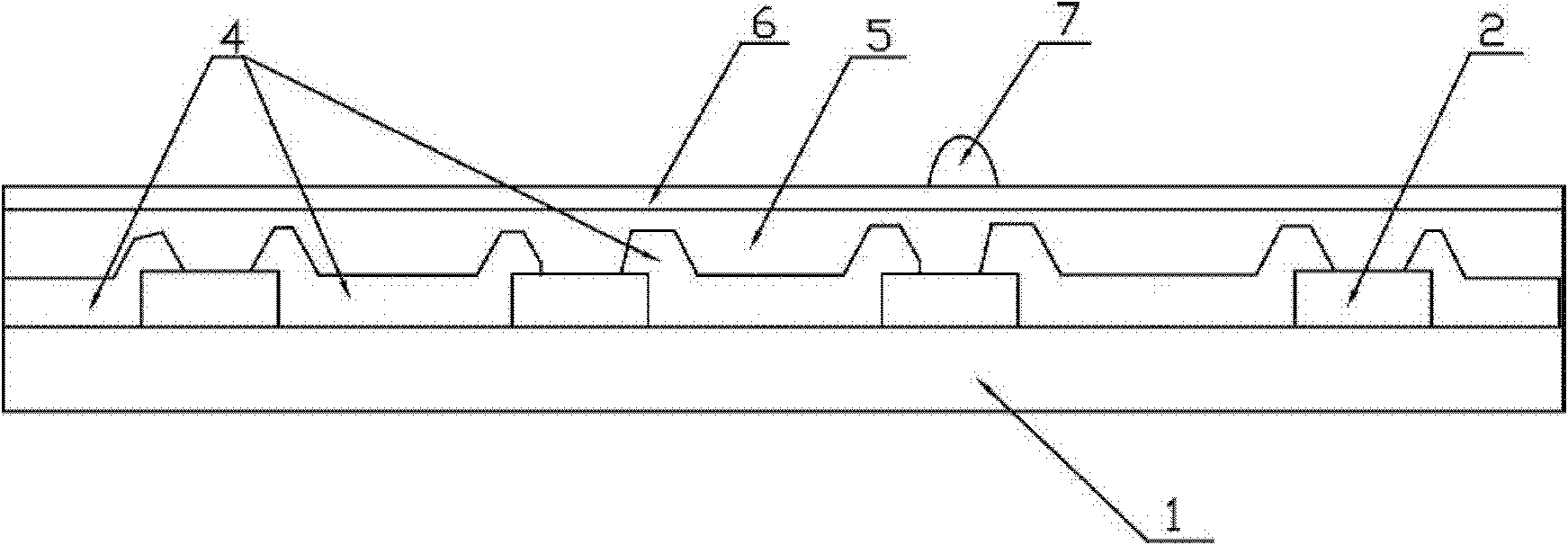

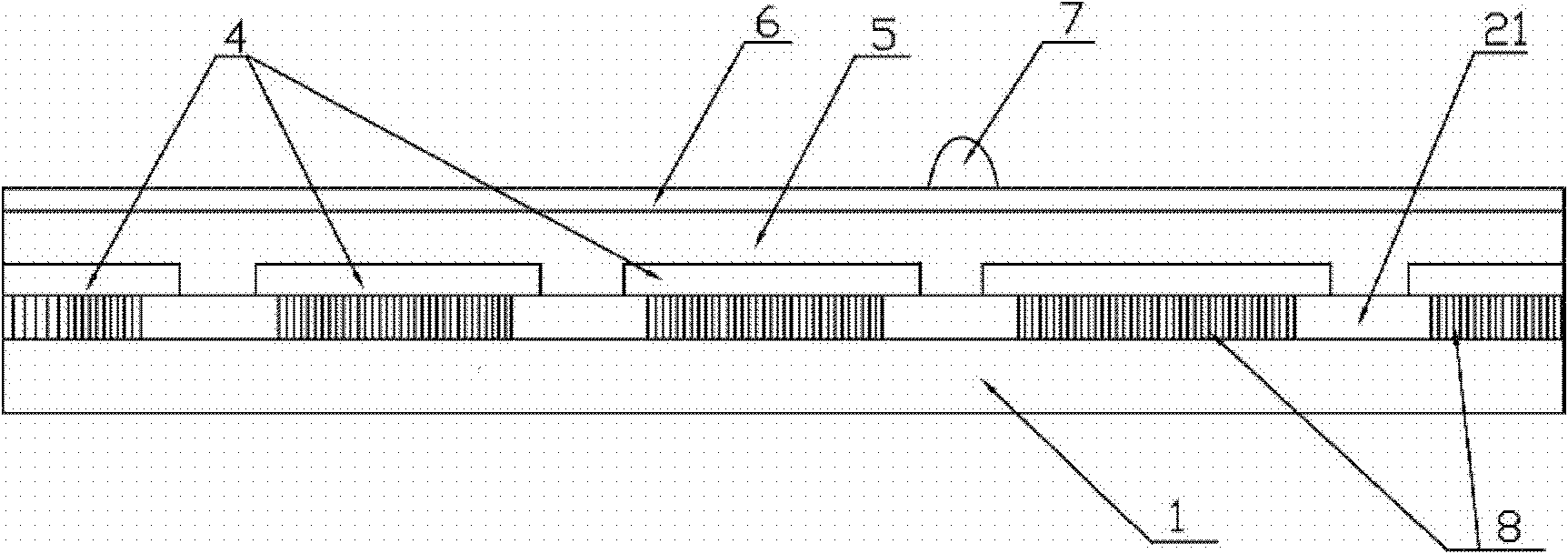

[0033] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

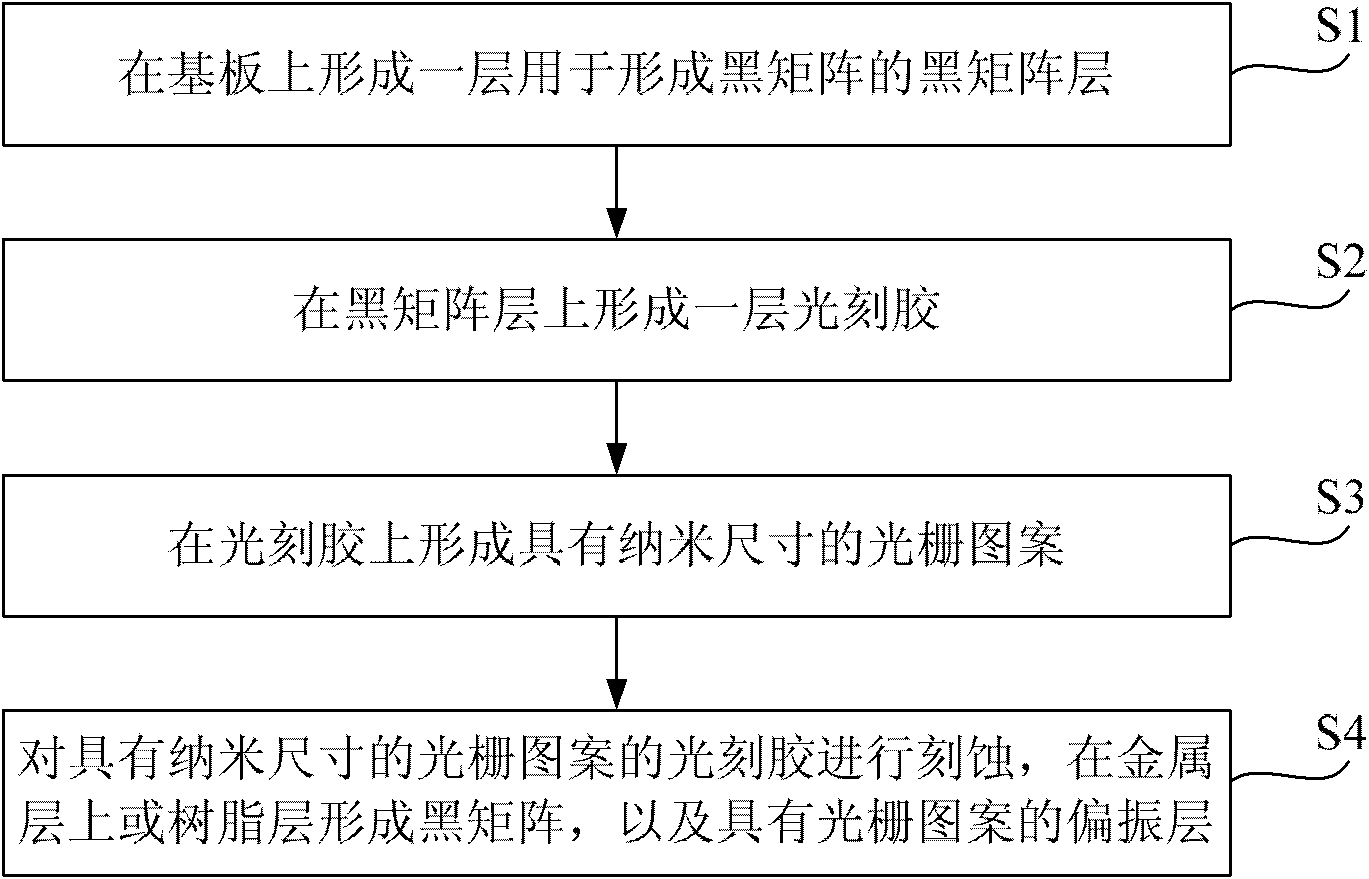

[0034] Such as figure 2 Shown is a flowchart of a method for manufacturing a color filter according to an embodiment of the present invention, including:

[0035] Step 1. Form an intermediate layer for forming a black matrix on the substrate;

[0036] The substrate may be a glass substrate. In this embodiment, the intermediate layer is a metal layer, specifically aluminum, or chromium, or gold or silver. The intermediate layer may also be a resin layer containing a conductive substance, and the conductive substance may be Nano-scale metal wires, such as silver wires, aluminum wires, etc.; or metal powder additives, so that the subsequently formed polarizing layer has certain electromagnetic characteristics. The i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com