Automobile lithium battery discharging balance method and balance system

A technology for balancing systems and lithium batteries, which is applied in the direction of battery continuous discharge, secondary battery charging/discharging, battery circuit devices, etc. It can solve the problems of unadjustable discharge current, poor battery balance, and too little discharge, etc., to prolong life , good effect, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment discloses a discharge balancing method for an automobile lithium battery, which is used to balance the difference between individual cells when the automobile lithium battery pack is in a discharging state, and the battery pack includes a plurality of single cells connected in series;

[0034] A DC-DC conversion circuit is connected to both ends of each single battery, and the input terminals of the DC-DC conversion circuit are connected to the two output voltage terminals of the battery pack; the purpose of the DC-DC conversion circuit It is to reduce the voltage at both ends of the battery pack to recharge the low-voltage single battery, realize energy transfer, and avoid the short board effect of the wooden barrel, that is: the discharge time is determined by the lowest single battery.

[0035] During the discharge process, the remaining power of the battery pack is monitored in real time; if the remaining power of the battery pack is 20% to 30%, the f...

Embodiment 2

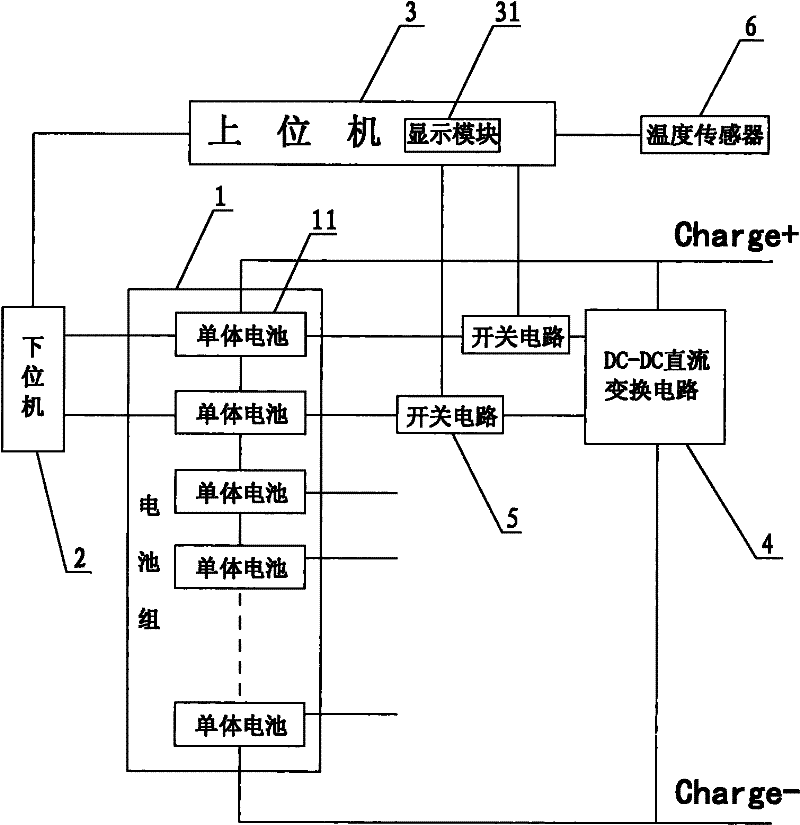

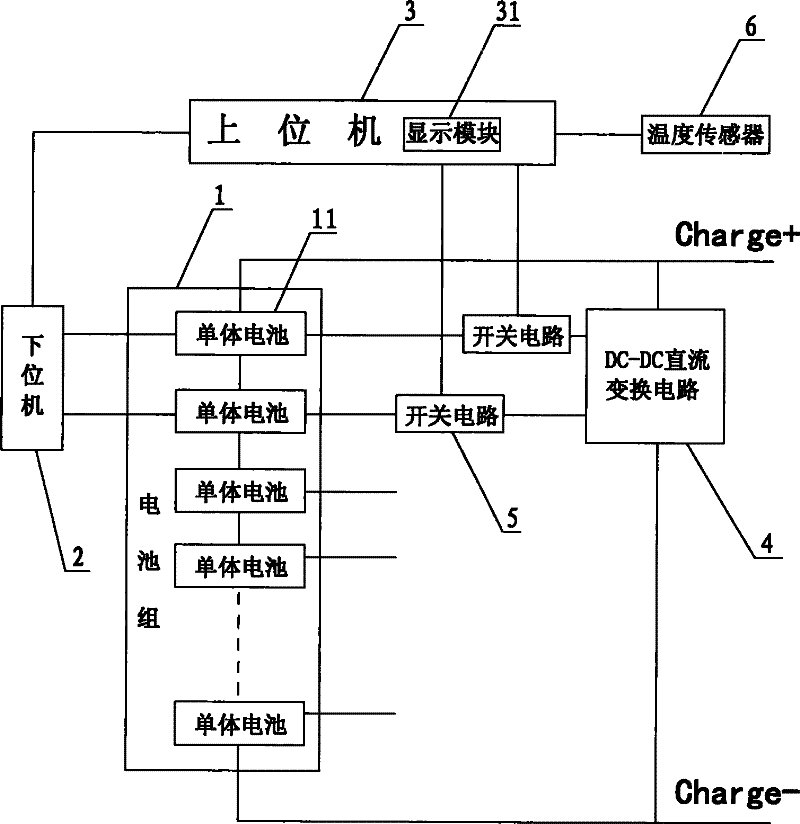

[0042] Such as figure 1As shown, this embodiment discloses a discharge balancing system for a lithium battery for an automobile, which is used to balance the difference between individual cells when the lithium battery pack of an automobile is in a discharging state. The battery pack 1 includes a plurality of single cells connected in series. body battery 11; the balance system includes: lower computer 2, upper computer 3, switch circuit 5, and DC-DC conversion circuit 4, lower computer 2 is a PLC or a single-chip microcomputer, and upper computer 3 is a main control module including a CPU , the switch circuit 5 can be a field effect tube; the input end of the DC-DC conversion circuit 4 is connected to both ends of the battery pack 1, and its output end is connected to each single battery 11 through a switch circuit 5 , carry out compensatory charging to each monomer battery 11; The lower computer 2 is connected to both ends of each said monomer battery 11, collects the voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com