Technical scheme of intermittent inflating turbine engine

A technology of turbine engine and technical solution, which is applied to engine components, gas turbine devices, machines/engines, etc., can solve the problems of restricting the bypass ratio and thrust-weight ratio of the engine, high outlet temperature of the gas turbine engine, and low thermal energy utilization efficiency. The effect of long service life, simple structure and improved thermal energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

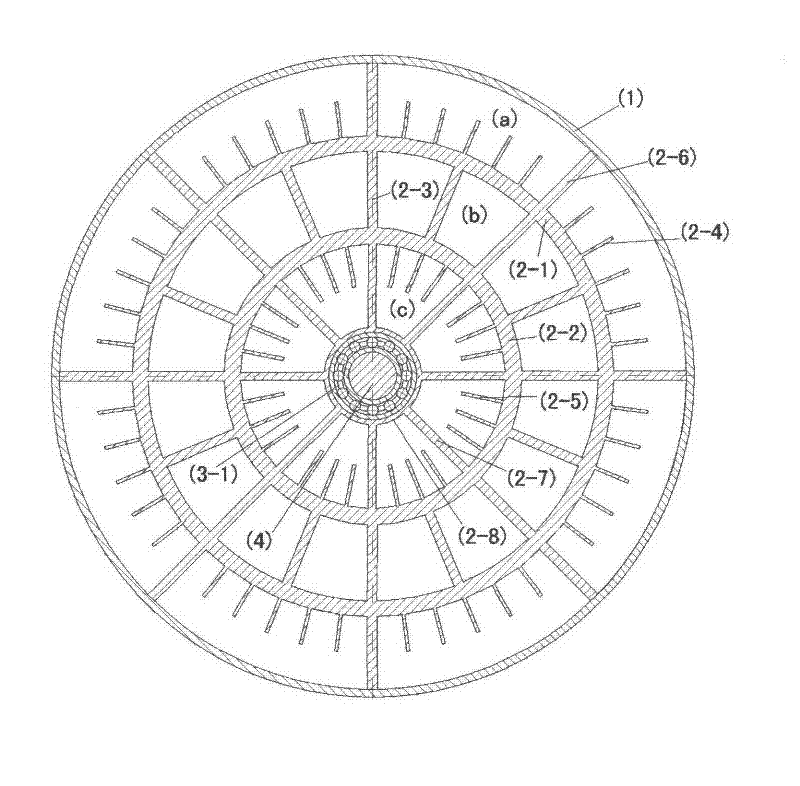

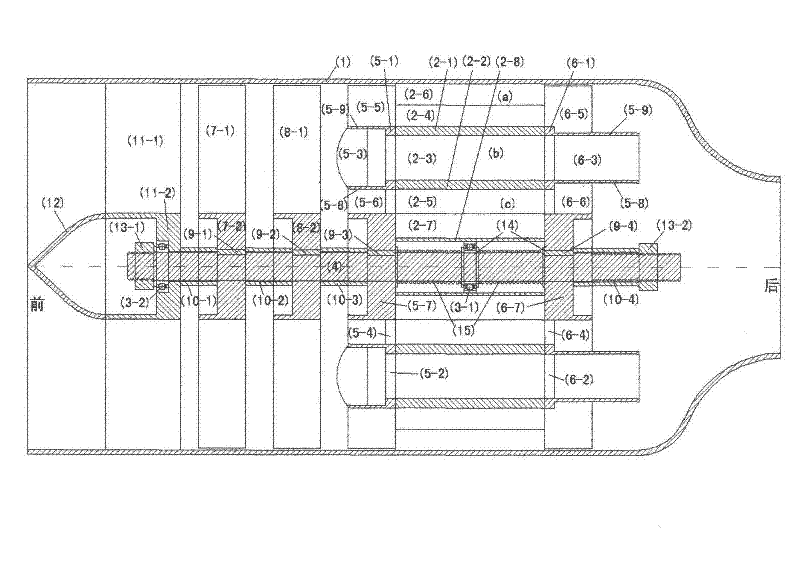

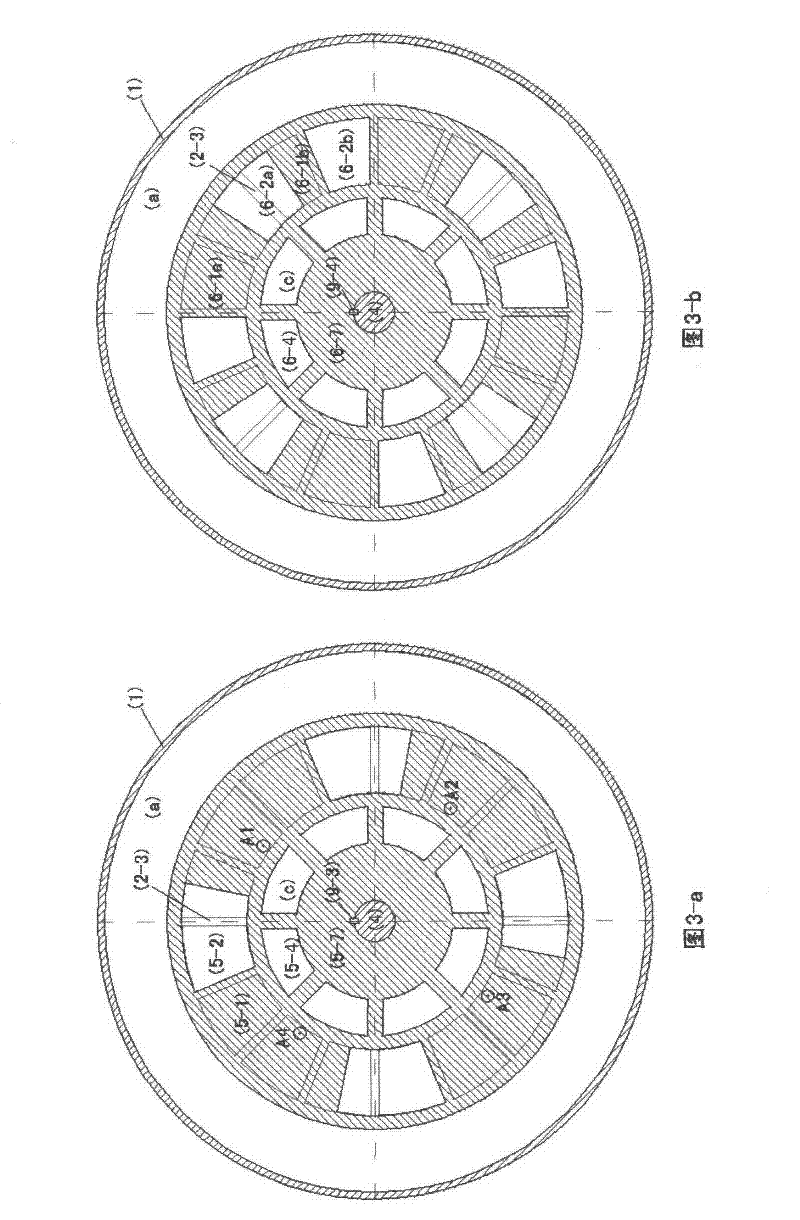

[0051] 1, the design of the combustion chamber stator (2) and the front and rear end covers (5, 6) of the combustion chamber is the technical core of the engine of the present invention. During the design process, it must be ensured that the combustion chamber has the characteristics of intermittent cycle ramming and ventilation and ignition work, that is, to ensure that the front and rear two functional end covers and the working state of the combustion chamber must have two most fundamental correspondences:

[0052] (1) Open - open - press ventilation;

[0053] (2) sealing - opening - ignition work.

[0054] The design steps of the combustion chamber stator and the front and rear end covers of the combustion chamber:

[0055] (1) Firstly, consider the application of starting, determine the output power of the engine and determine the corresponding relationship between the appropriate front and rear end covers and the combustion chamber, and find the working cycle T.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com