Temperature compensation current reference circuit applied to integrated circuit

A technology of temperature compensation and current reference, applied in the direction of adjusting electrical variables, control/regulation systems, instruments, etc., can solve problems such as small resistance value, increased cost of integrated circuits, and difficulty in controlling absolute value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

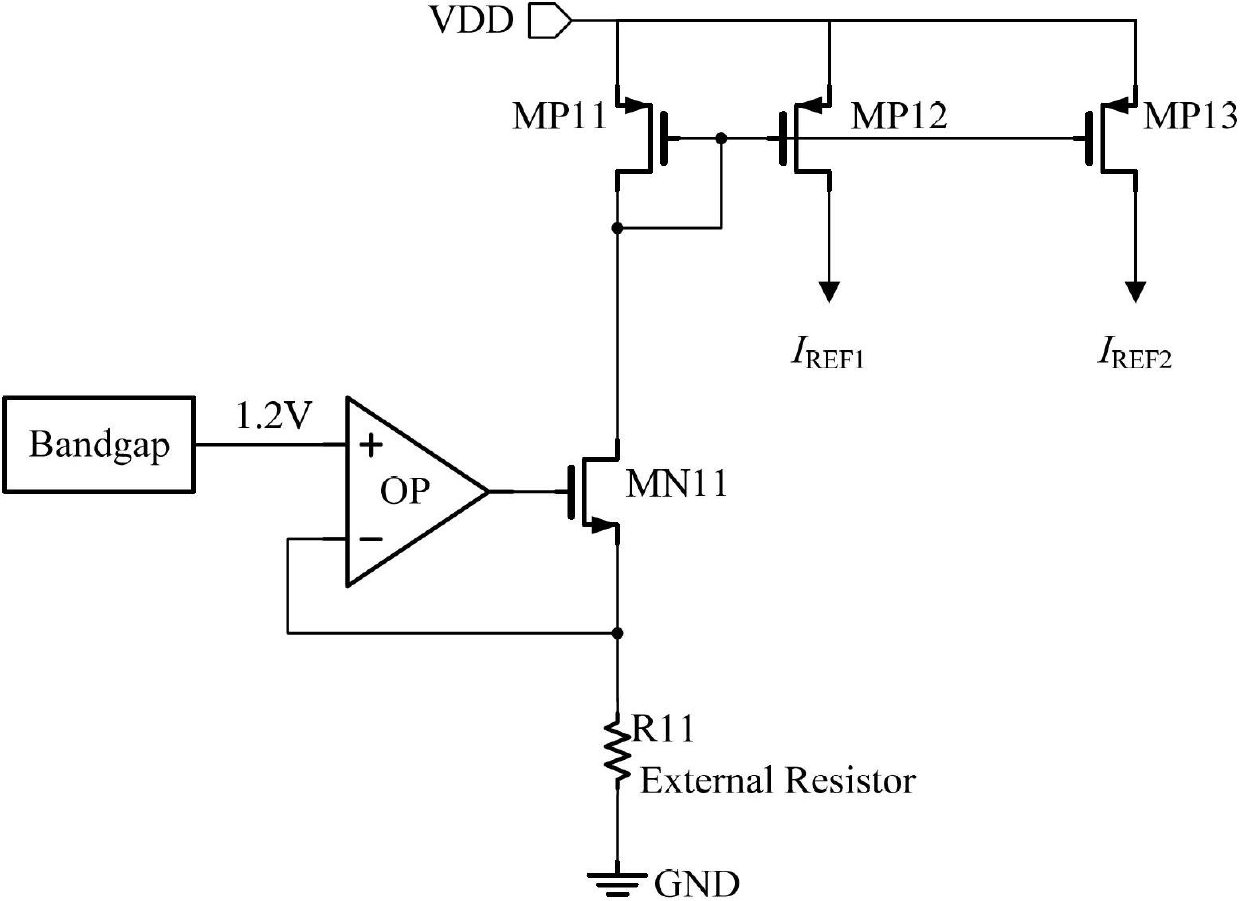

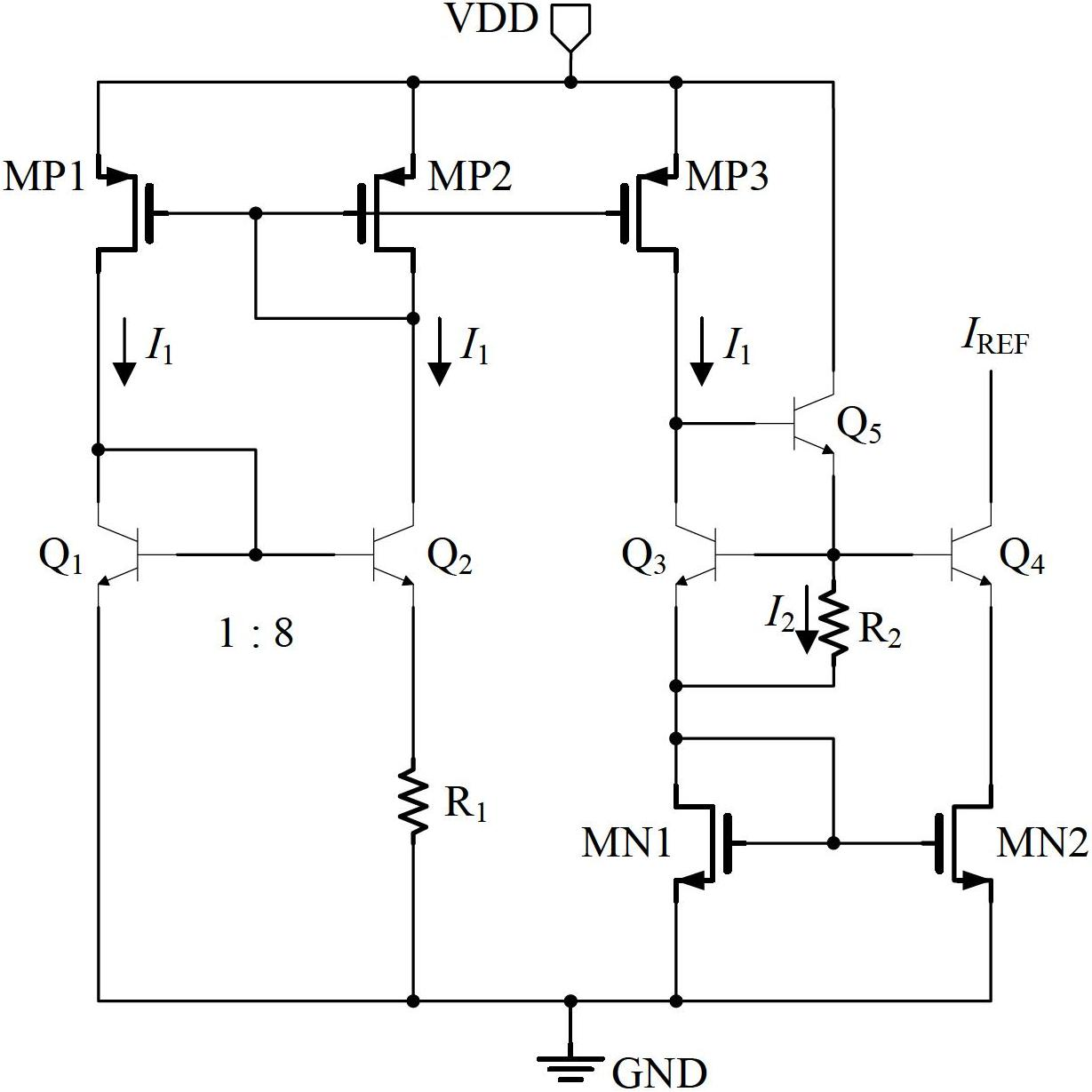

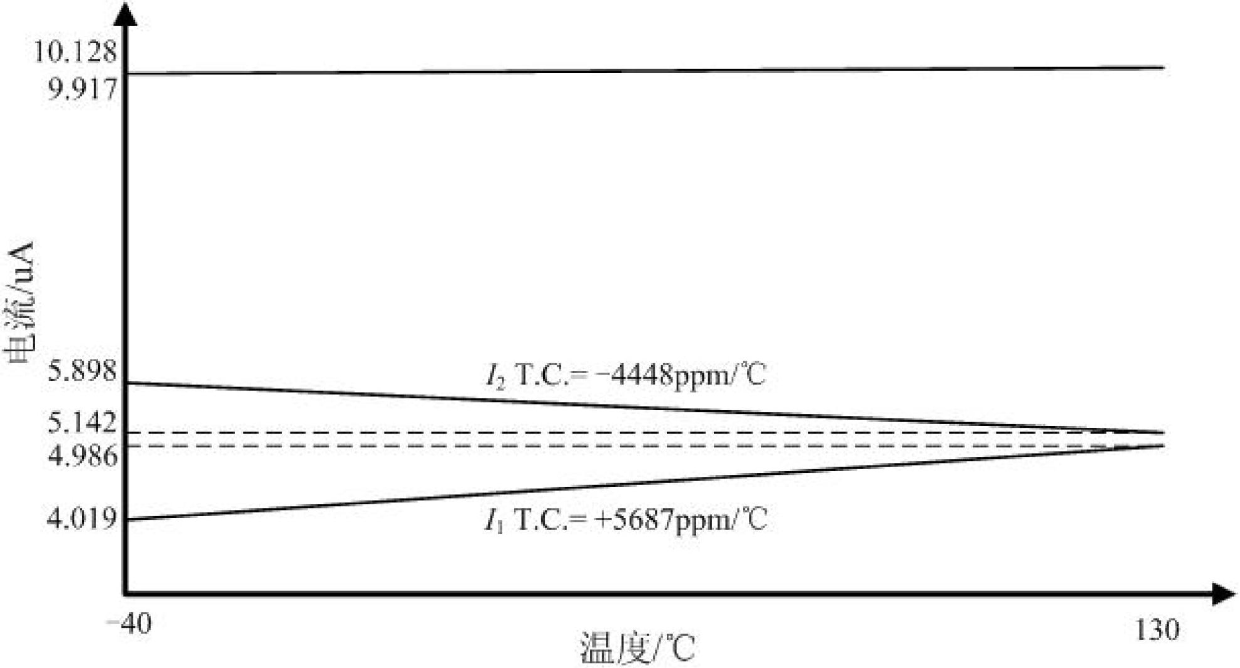

[0019] The temperature compensation current reference circuit designed by the present invention is as figure 2 As shown, I REF is the temperature-compensated reference current generated by the present invention. MP1, MP2, and MP3 are mutually matching current mirrors, the current mirror ratio is 1:1:1, and its type can be PMOS transistors or PNP transistors; transistors Q1 and Q2 are mutually matching NPN transistors, and the emitter of Q2 The area is 8 times that of Q1; resistor R1 adopts a high-value polycrystalline resistor with a temperature coefficient of -2341ppm / ℃; transistors Q3 and Q4 match each other, and the emitter area ratio is 1:1; MN1 and MN2 are current mirrors that match each other. The ratio of current mirror is 1:1, and its type can be NMOS transistor or NPN triode; resistor R2 adopts P-type ion implantation resistor with temperature coefficient of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com