Vibration detection device, air pressure detection terminal, and acceleration detection system

A technology of vibration detection and air pressure detection, which is applied in the direction of measuring acceleration, speed/acceleration/shock measurement, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

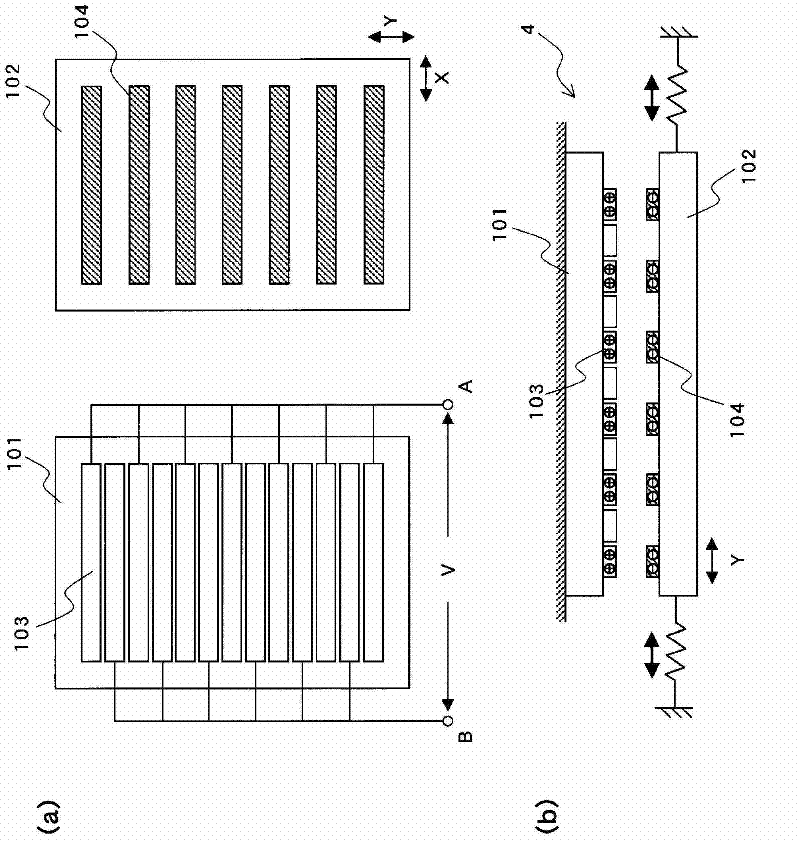

[0032] refer to Figure 1 ~ Figure 4 The configuration of the vibration detection system 1 according to the first embodiment of the present invention will be described.

[0033]

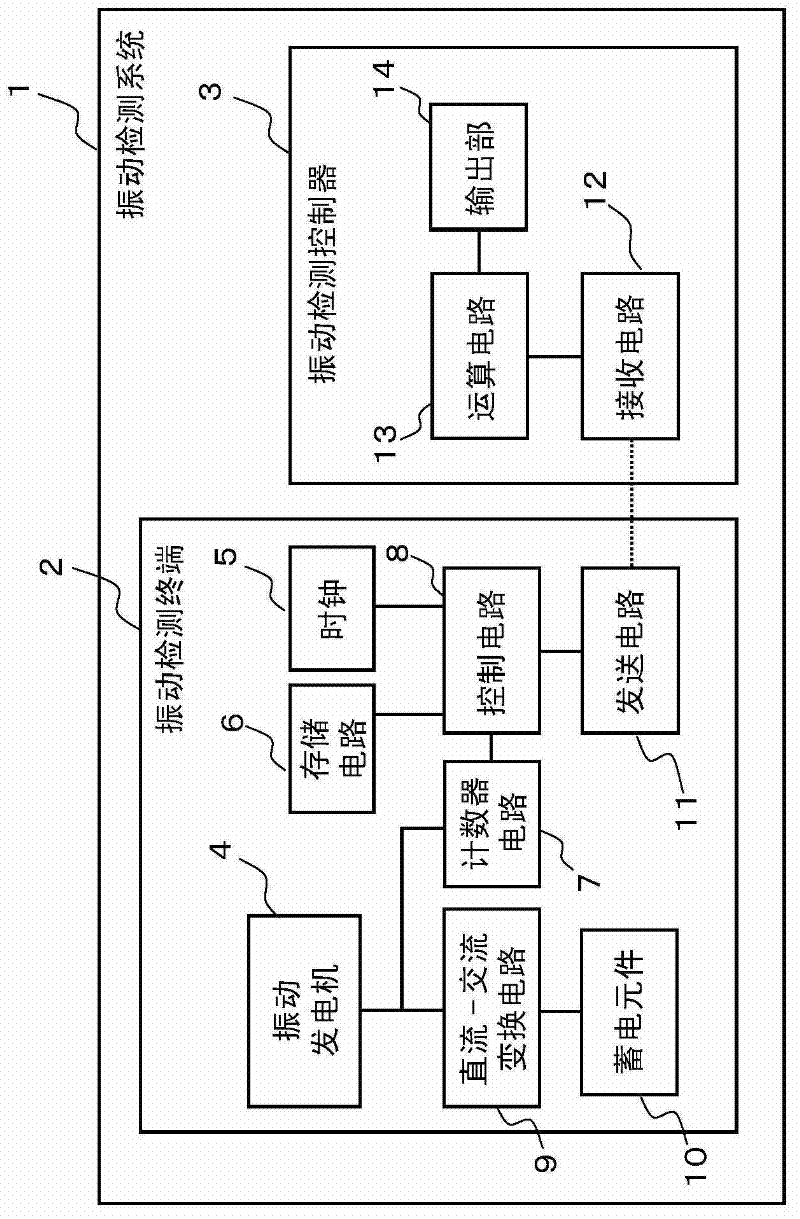

[0034] figure 1 It is a block diagram for explaining the configuration of the vibration detection system 1 .

[0035] The vibration detection system 1 is composed of a vibration detection terminal 2 and a vibration detection controller 3 . The vibration detection terminal 2 includes a vibration generator 4 , a clock 5 , a storage circuit 6 , a counter circuit 7 , a control circuit 8 , a DC-AC conversion circuit 9 , an electric storage element 10 , and a transmission circuit 11 . The vibration detection controller 3 includes a receiving circuit 12 , an arithmetic circuit 13 , and an output unit 14 .

[0036] The vibration detection system 1 measures the vibration frequency of the vibration generator 4 and the time required for the vibration in the vibration detection terminal 2 . In addition, in...

Embodiment 1

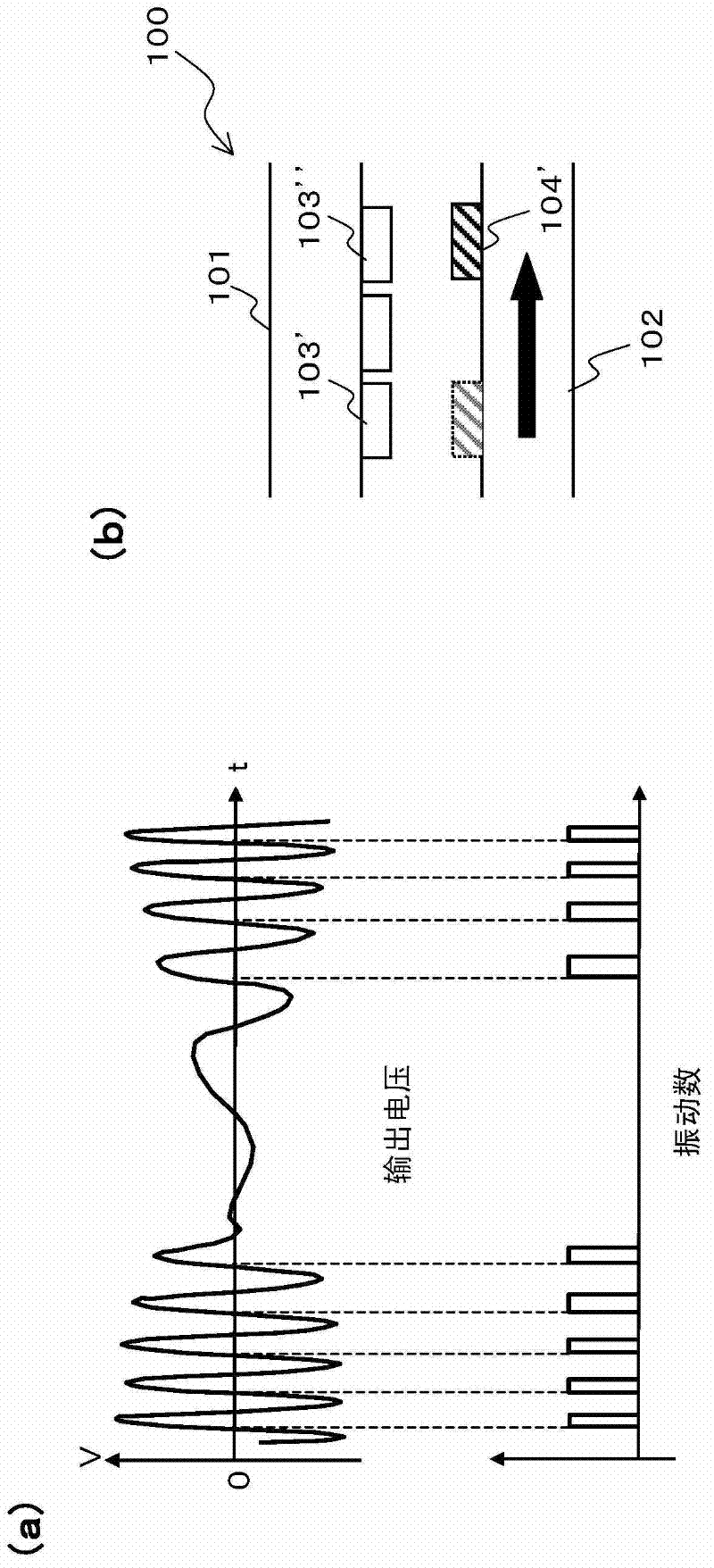

[0066] refer to Figure 5 The calculation method of the acceleration related to the first embodiment of the vibration detection system 1 will be described. Figure 5 (a) and Figure 5 (b) is a flowchart showing the calculation method of the acceleration related to the first embodiment. Figure 5 (a) is the processing in the vibration detection terminal 2, Figure 5 (b) is processing in the vibration detection controller 3 . In addition, in Embodiment 1, the control circuit 8 is based on Figure 4 No.1 of the operation table shown is controlled.

[0067] refer to Figure 5 (a), in vibration detection terminal 2, if vibration generator 4 vibrates (S1), then control circuit 8 adopts the clock signal that obtains from clock 5, by the vibration of vibration generator 4 in the fixed time by counter circuit 7 The number is counted (S2). Here, the fixed time can be freely set by the user, for example, it is set to 1 second. Next, the control circuit 8 judges whether or not the...

Embodiment 2

[0070] Next, refer to Figure 6 The calculation method of the acceleration related to the second embodiment of the vibration detection system 1 will be described. Figure 6 It is a flowchart showing the calculation method of the acceleration in the second embodiment. Figure 6 The processing shown in the flowchart of is performed in the vibration detection terminal 2 . In addition, in Embodiment 2, the control circuit 8 is based on Figure 4 Control No.2 of the operation table shown.

[0071] In vibration detection terminal 2, if vibration generator 4 vibrates (S11), then control circuit 8 adopts the clock signal that obtains from clock 5, counts the vibration number of vibration generator 4 in fixed time by calculator 7 ( S12). Here, the fixed time can be freely set by the user, for example, it is set to 60 seconds. The control circuit 8 creates data for acceleration calculation which associates the counted number of vibrations of the vibration generator 4 with a fixed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com