Smoke sulfur-removing and dust-removing system

A desulfurization system, desulfurization and dust removal technology, applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of difficult control of flue gas moisture content, large floor space, long installation period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

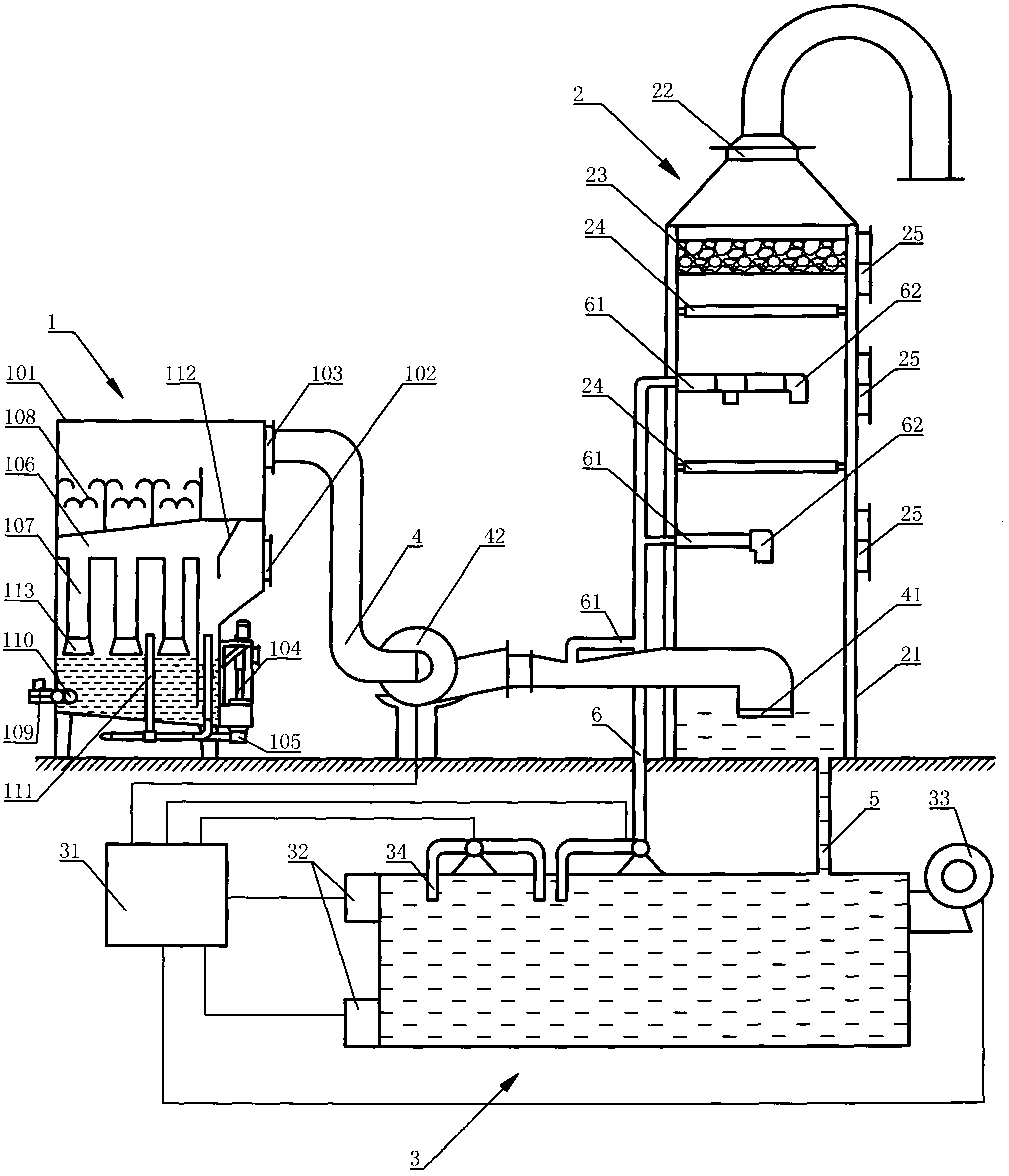

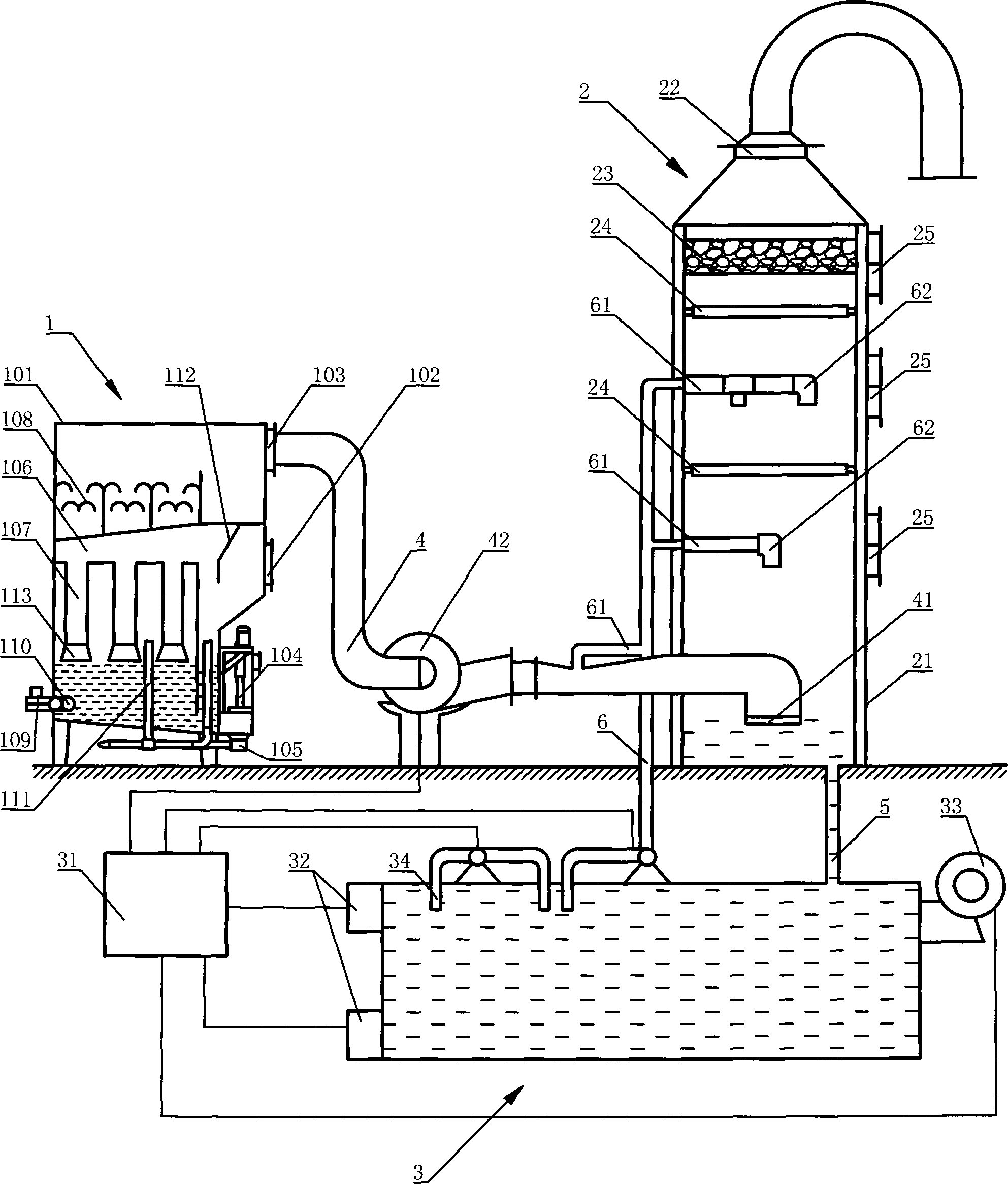

[0019] The flue gas desulfurization and dust removal system of the present invention comprises a desulfurization and dust removal tower 2, an air outlet pipe 4, a dust collector 1 arranged on one side of the desulfurization and dust removal tower 2 and connected to the lower part of the desulfurization and dust removal tower 2 through the air outlet pipe 4, and arranged on the desulfurization and dust removal tower 2 and the reaction pool 3 connected to the bottom of the desulfurization and dust removal tower 2 through the connecting pipe 5. The middle part of the air outlet pipe 4 is provided with an induced draft fan 42, and one end extends into the desulfurization and dust removal tower 2, and extends into the pipe in the desulfurization and dust removal tower 2. An impactor 41 is installed at the mouth; an infusion pipe 6 is connected to the reaction pool 3; an infusion pump is installed on the infusion pipe 6 and three outlet branch pipes 61 extending into the interior of t...

example 2

[0022] The flue gas desulfurization and dust removal system of the present invention, as shown in the figure, wherein the dust collector 1 includes a housing 101, a dust inlet 102 is provided on one side of the housing 101 shown, and a connecting air outlet is provided above the dust inlet 102. The air outlet 103 of the pipeline 4 is provided with an electric push rod 104 on the outer side of the lower part, a drain outlet 105 is provided at the bottom, an overflow device 111 communicated with the inside of the housing 101 is provided outside the bottom, and a joint connected with the dust inlet 102 is provided inside. Box 106; Dust inlet 102 is provided with dust baffle 112; Nozzle 113 is provided at the nozzle of air supply pipe 107; On the other side of the casing 101 corresponding to the electric push rod 104, a flushing head 110 is installed thereon. After the flue gas enters the interior of the dust collector through the dust inlet 102, the larger dust particles in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com