Bonding equipment for chips and wafers

A wafer bonding and chip technology, applied in welding equipment, optomechanical equipment, precision positioning equipment, etc., can solve the problems of manipulator offset, pick up and release chip unfavorable force control, etc., to achieve the effect of ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, specific implementation manners of the present invention will be described in detail with reference to the accompanying drawings.

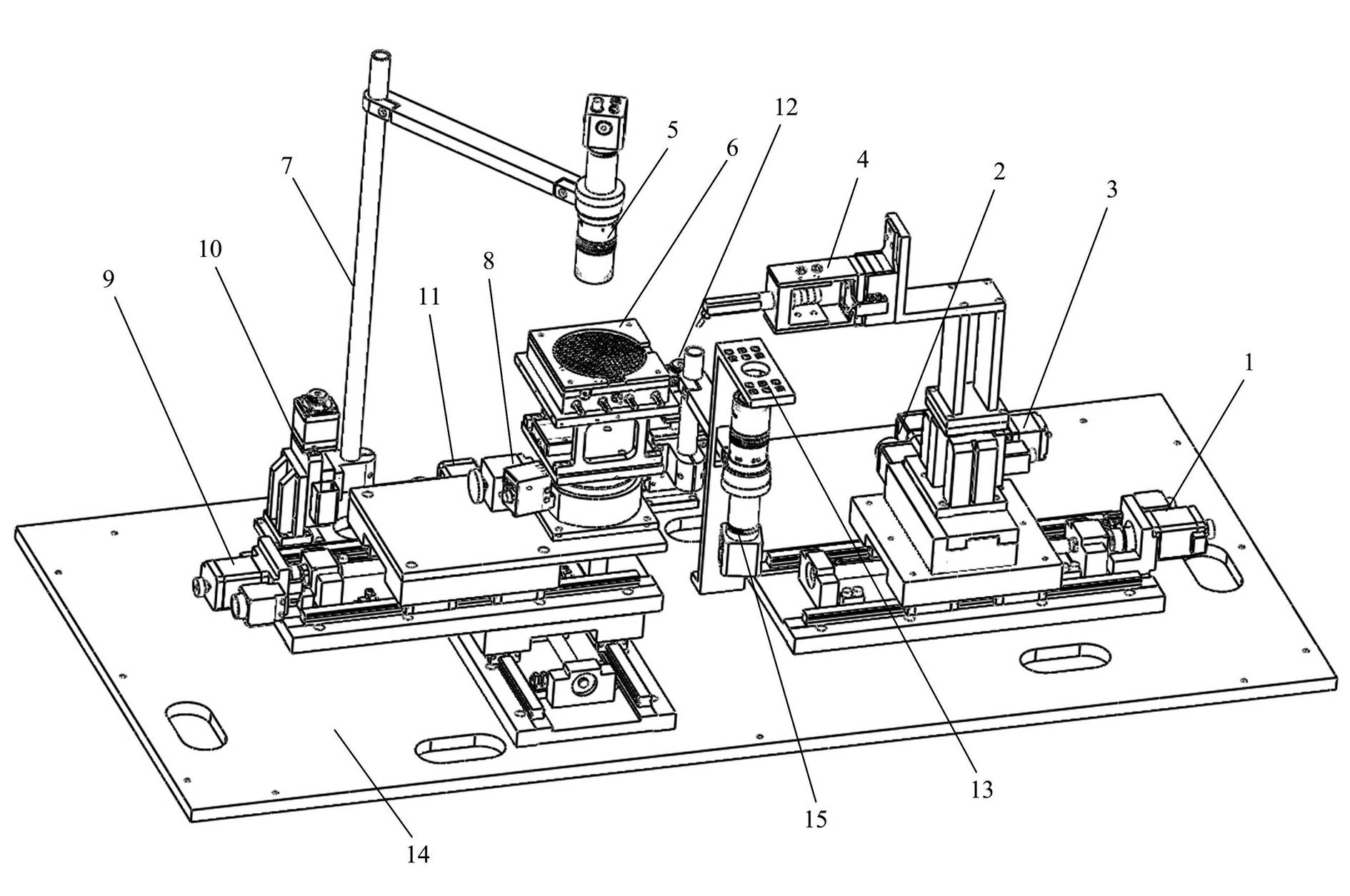

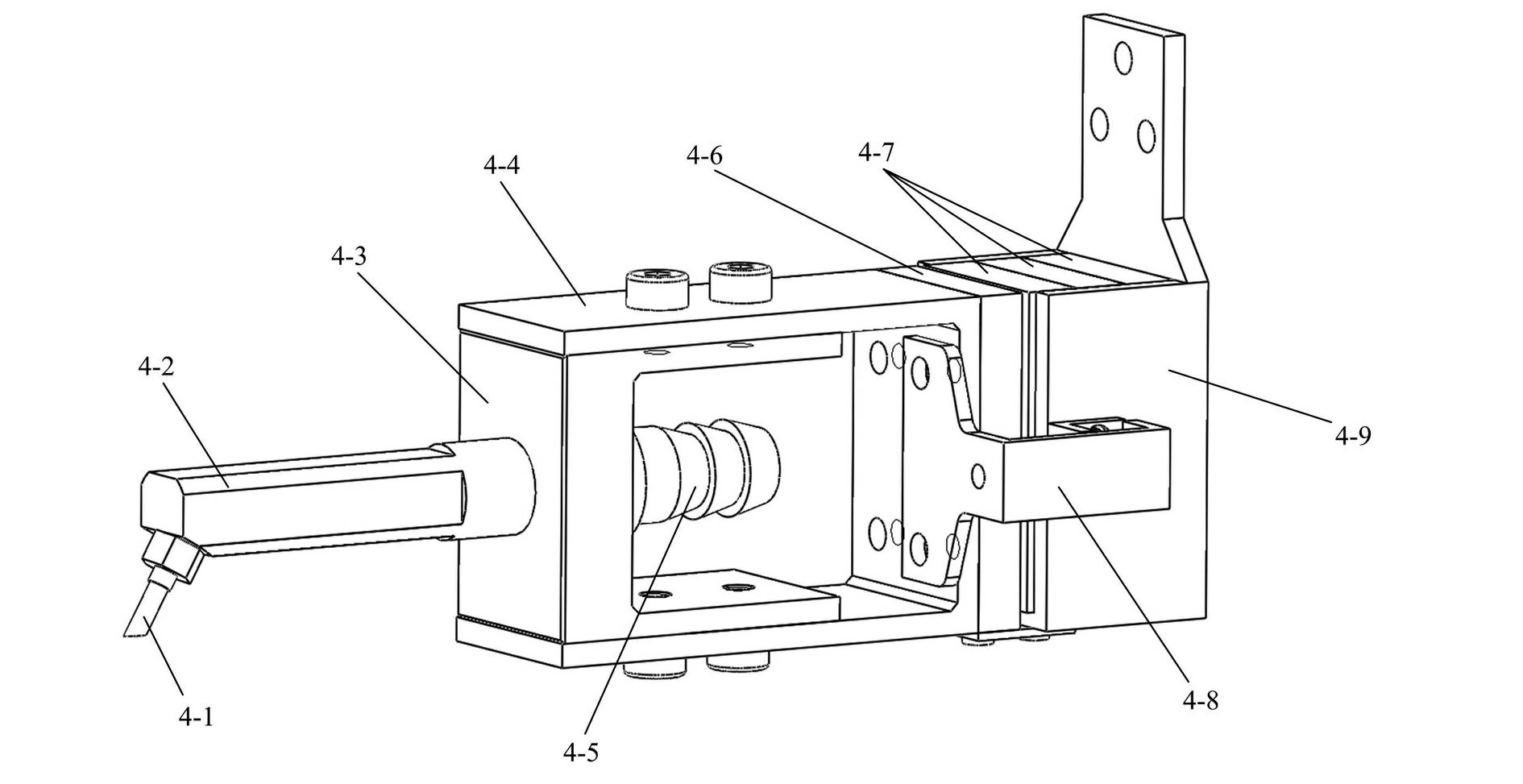

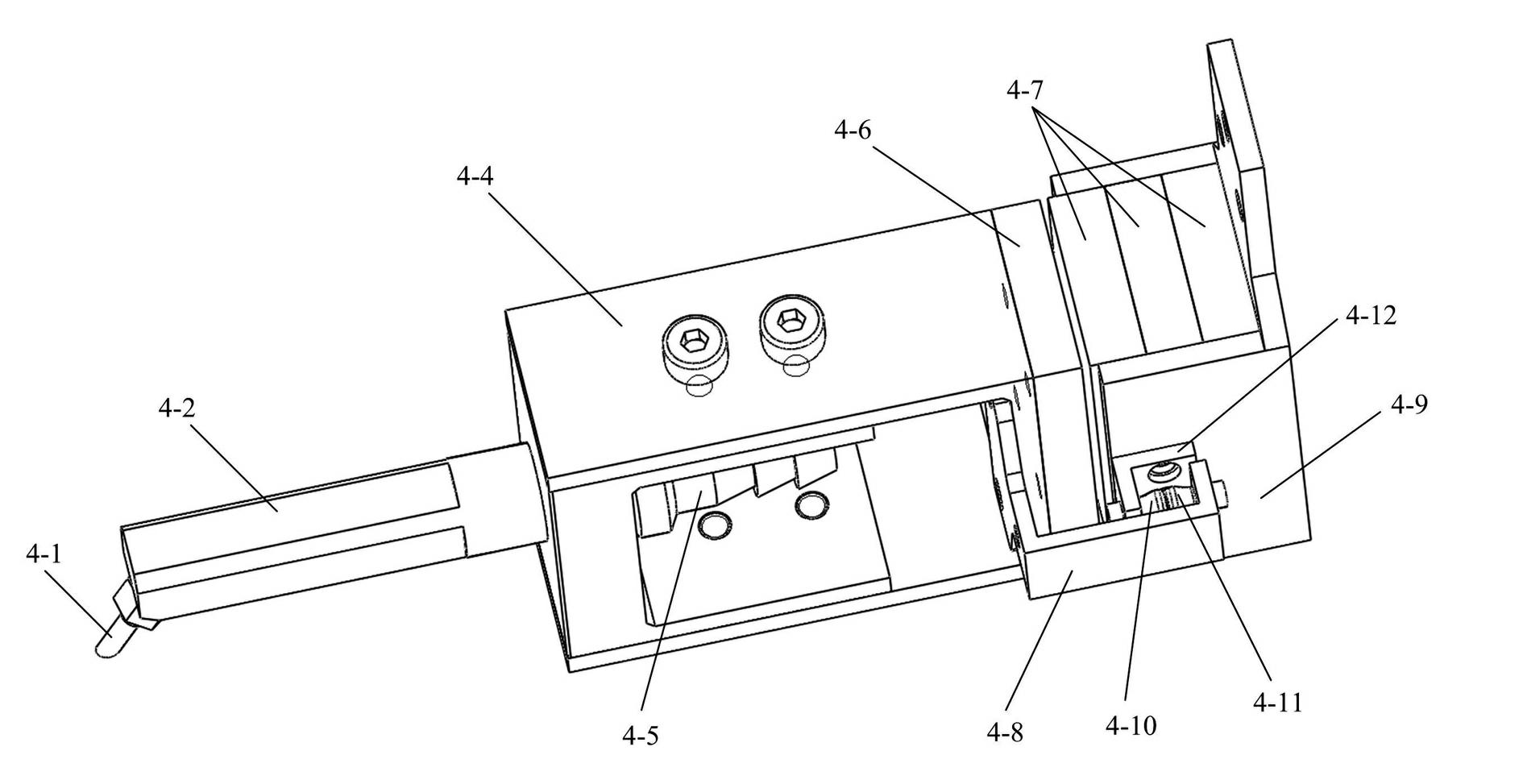

[0020] figure 1 It is a structural diagram of the chip and wafer bonding equipment of the present invention. Such as figure 1 As shown, the bonding equipment is installed on the bottom plate 14, including the wafer stage 6, the storage assembly 13, the operator 4, the microscopic system and the external control system ( figure 1 not shown). The wafer table 6 is used to fix a wafer, and is also a working carrier during bonding. A heating device is arranged on the wafer table 6, and the heating device is used to heat the chip and the wafer to the bonded state during the bonding process. to the desired temperature. The storage component 13 is used to store multiple chips, and the multiple chips may be of the same type or of different types. The operating hand 4 is used to pick up a chip from the storage component 13, and tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com