Active photoelectric marking method for MEMS infrared light supply array

An infrared light source and photoelectric identification technology, applied in the field of photoelectric identification, can solve the problems of inability to meet all-weather work requirements, small reflected light field of view, low recognition efficiency, etc., and meet all-weather work requirements, high electro-optical conversion efficiency, and recognition efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] MEMS infrared light source array active photoelectric identification method, the method is realized by the following steps:

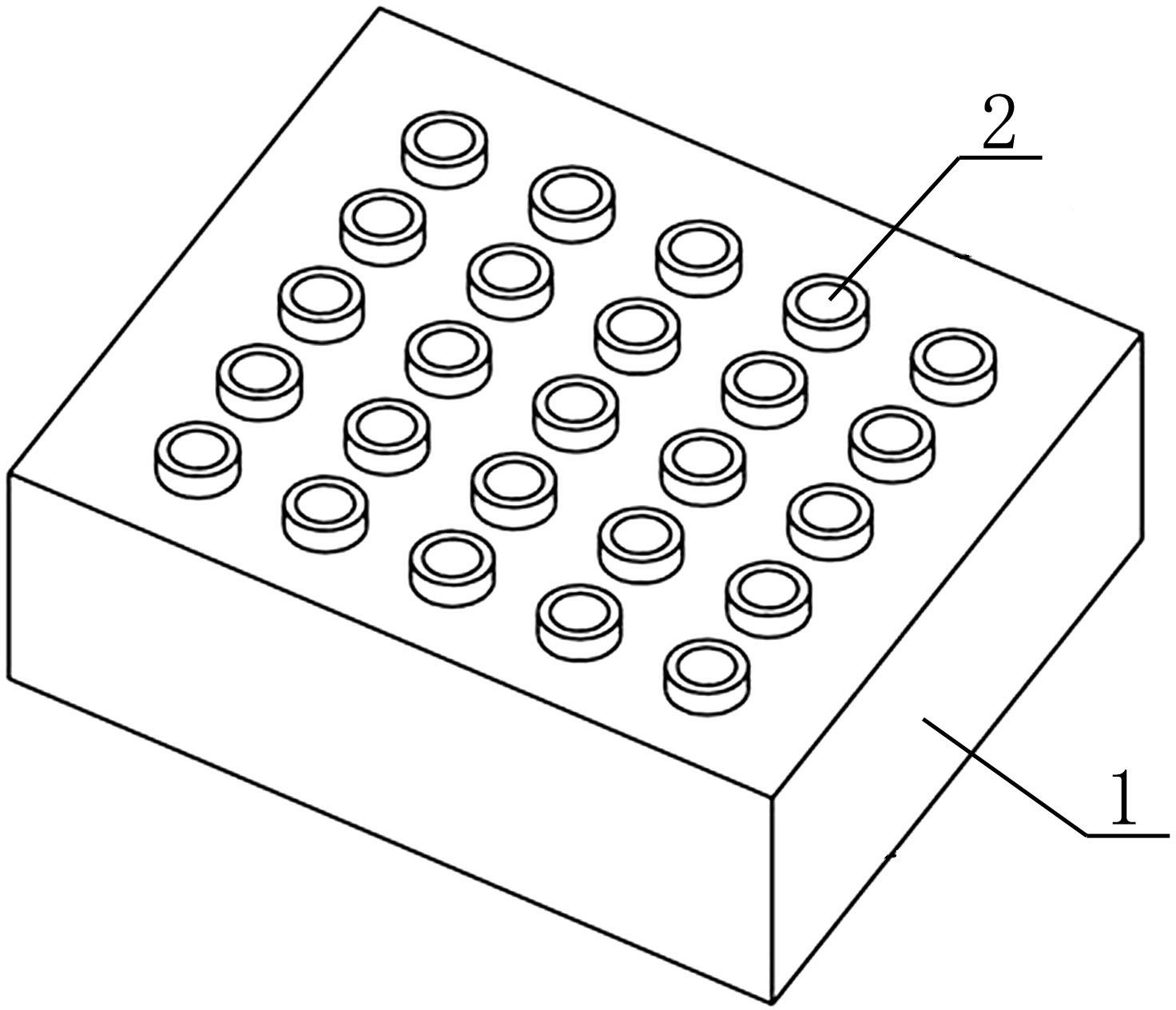

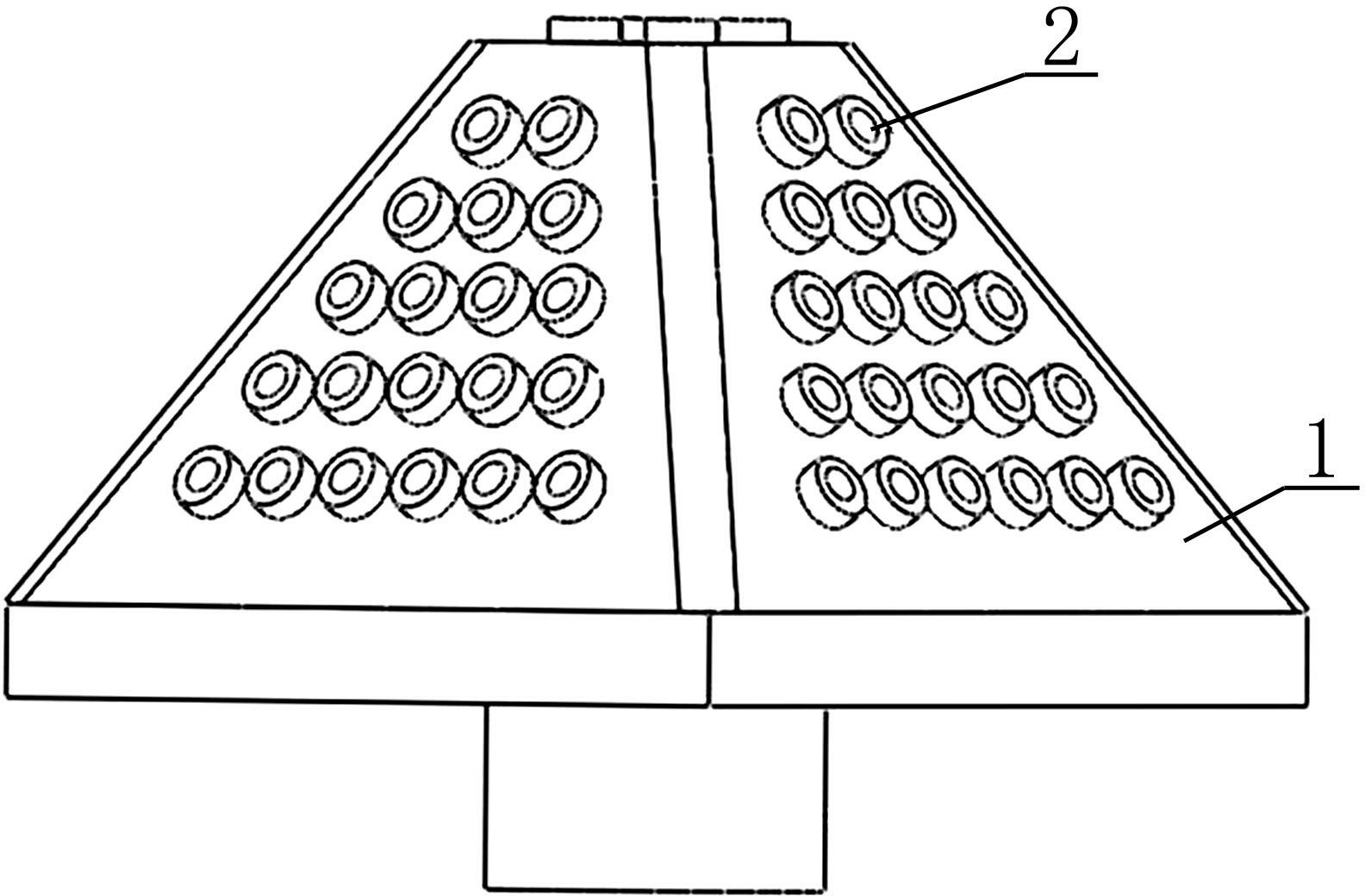

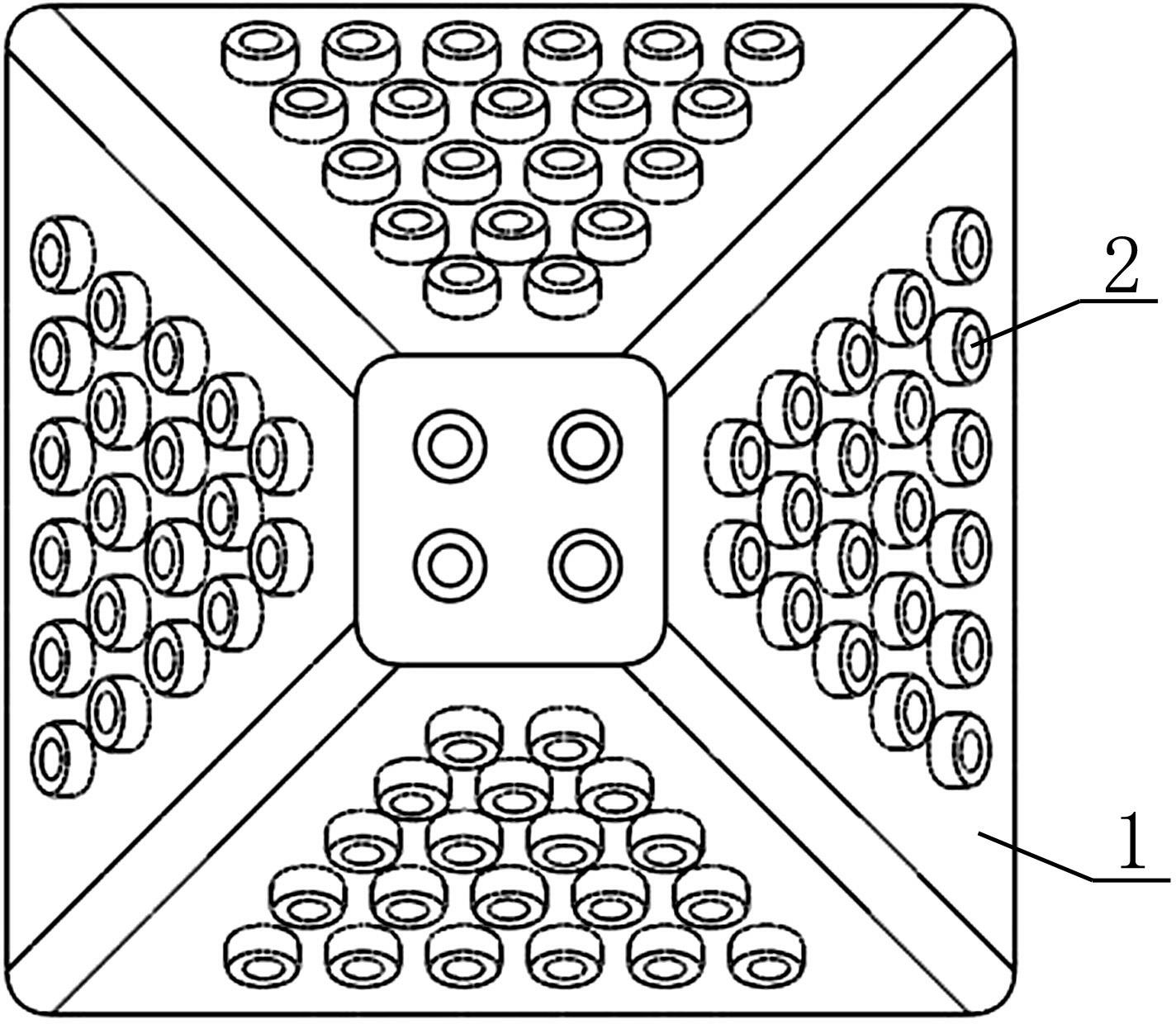

[0017] a. Making an infrared light source array module: select the base 1 and several MEMS infrared light sources 2, and arrange each MEMS infrared light source 2 on the surface of the base 1 to form an infrared light source array; the base 1 and each MEMS infrared light source 2 are shared Form infrared light source array module;

[0018] b. Point radiation source beacon detection: such as Figure 4 As shown, the active point light source photoelectric marking system is formed by FPGA, driving power supply, and infrared light source array module, and the active point light source photoelectric marking system is installed on the beacon; the driving power is each MEMS infrared light source in the infrared light source array module 2Provide driving voltage; FPGA controls the driving voltage output by the driving power supply to control the radiation of ...

Embodiment 2

[0024] MEMS infrared light source array active photoelectric identification method, the method is realized by the following steps:

[0025] a. Making an infrared light source array module: select the base 1 and several MEMS infrared light sources 2, and arrange each MEMS infrared light source 2 on the surface of the base 1 to form an infrared light source array; the base 1 and each MEMS infrared light source 2 are shared Form infrared light source array module;

[0026] b. Point radiation source beacon detection: such as Figure 4 As shown, the active point light source photoelectric marking system is formed by FPGA, driving power supply, and infrared light source array module, and the active point light source photoelectric marking system is installed on the beacon; the driving power is each MEMS infrared light source in the infrared light source array module 2Provide driving voltage; FPGA controls the driving voltage output by the driving power supply to control the radiation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com