High-pressure low-temperature triaxial corrosion experimental device and experimental method thereof

An experimental device, high-pressure and low-temperature technology, applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as lack of research on rock mass dissolution characteristics and dissolution depth, and achieve simple structure, convenient operation, and removal of danger. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

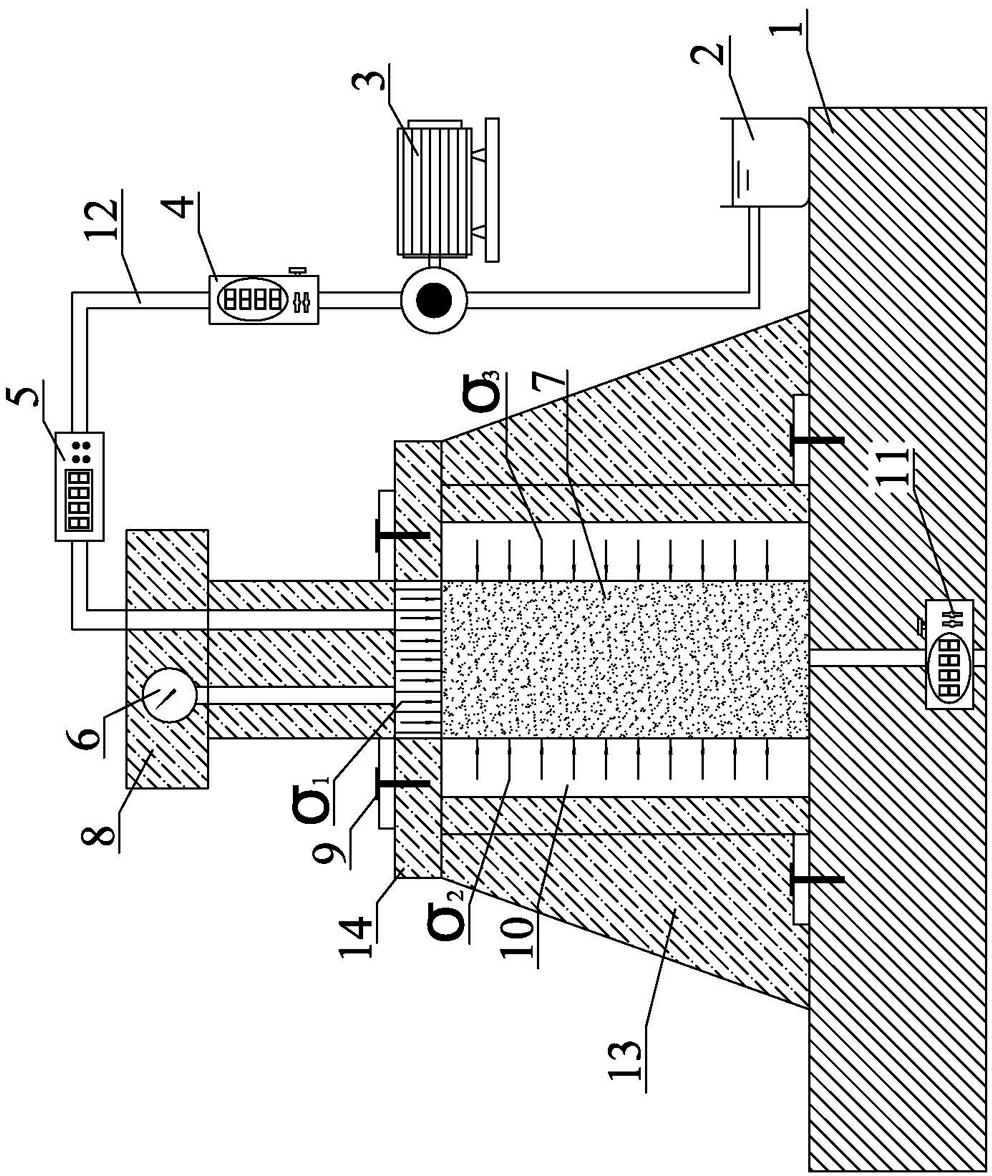

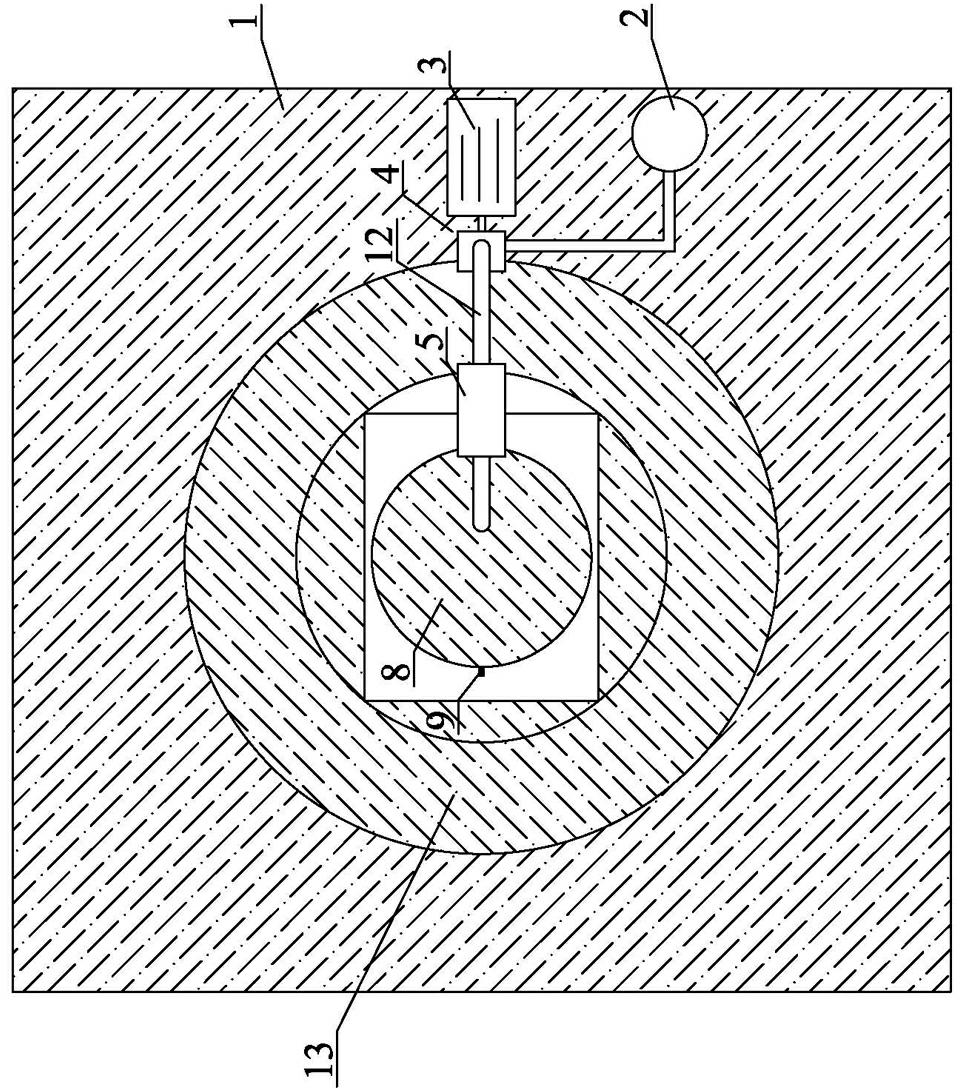

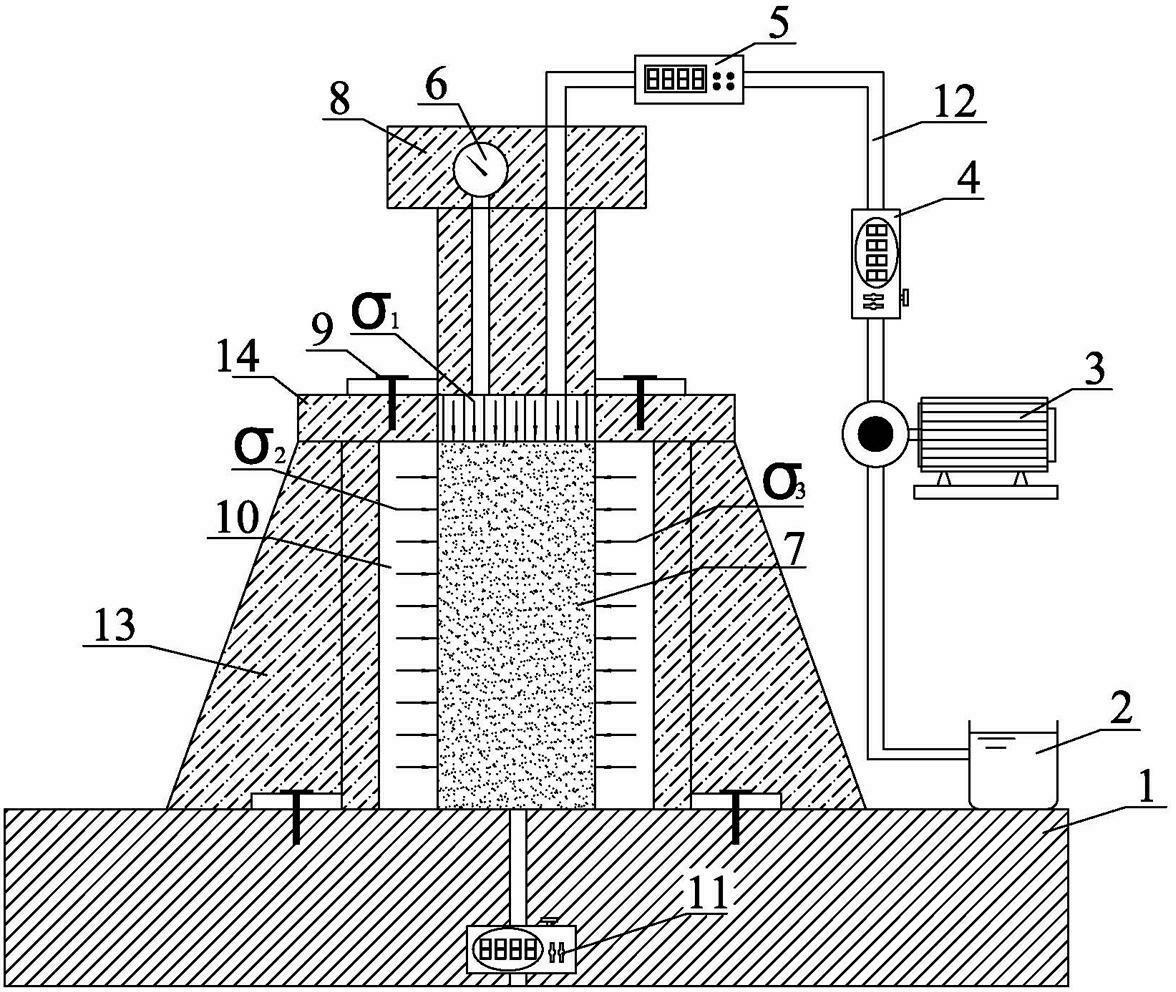

[0024] like figure 1 , figure 2 As shown, this embodiment is a high-pressure low-temperature triaxial corrosion experimental device, including a test bench 1, a confining pressure chamber seat 13, a confining pressure chamber cover 14, and an axial pressure servo 8, etc., wherein the central part of the test bench 1 is provided with a guide Orifice and install flowmeter Ⅱ11. The confining pressure chamber seat 13 is riveted on the test bench 1 through rivets 9, and the top is fixed with the confining pressure chamber cover 14. The outside of the confining pressure chamber seat 13 is in the shape of a truncated cone, and the inside is a hollow cylindrical confining pressure chamber 10. The confining pressure chamber 10 is used to place the test sample, and can apply a horizontal confining pressure σ to the sample. 2 , σ 3 . The confining pressure chamber cover 14 is a flat plate with a through hole whose diameter matches the sample diameter. Corresponding to the through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com