End surface grinder control system

A control system and knife sharpening machine technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of easy accidents, high labor intensity, low production efficiency, etc., achieve uniformity, ensure consistency, and improve grinding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

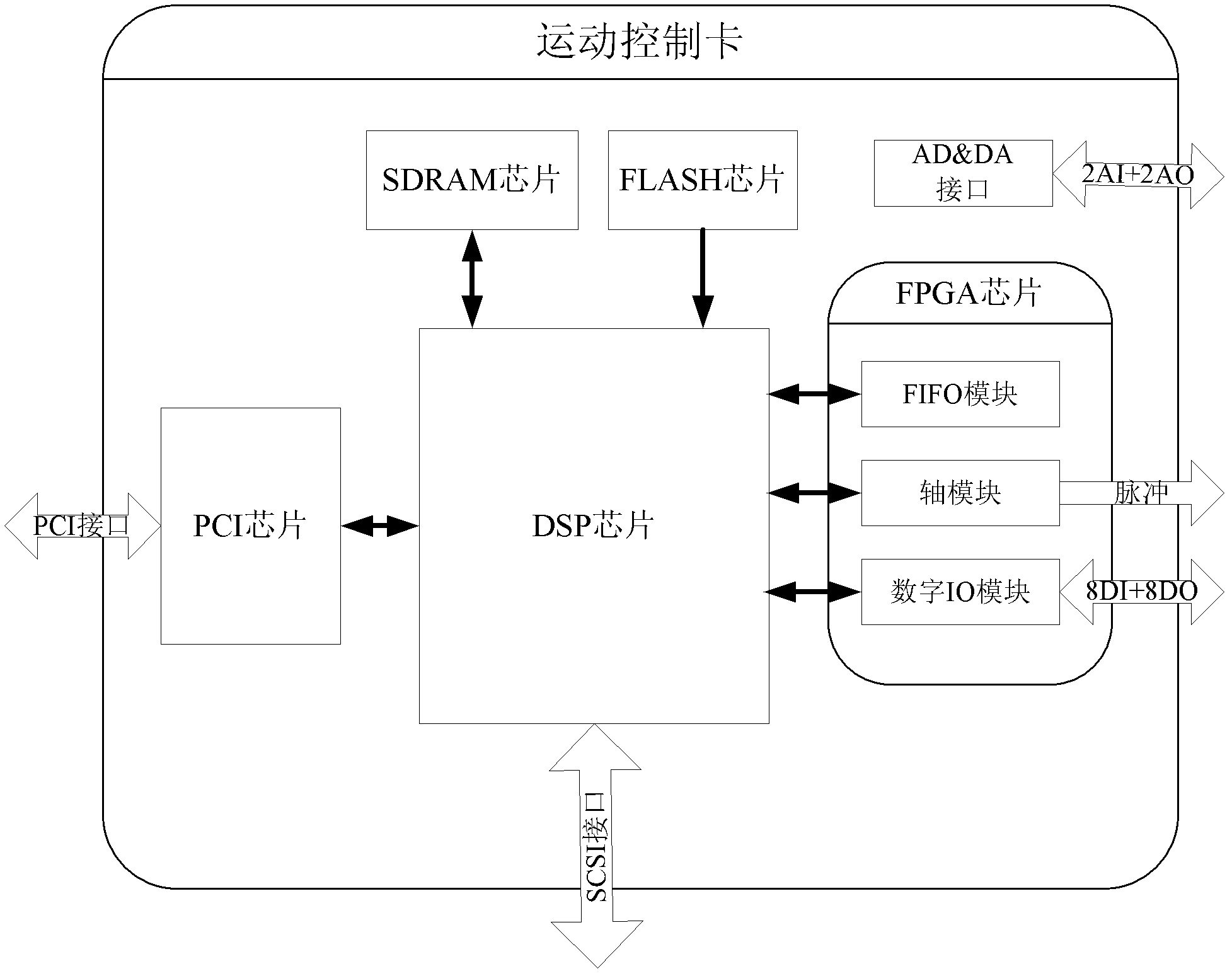

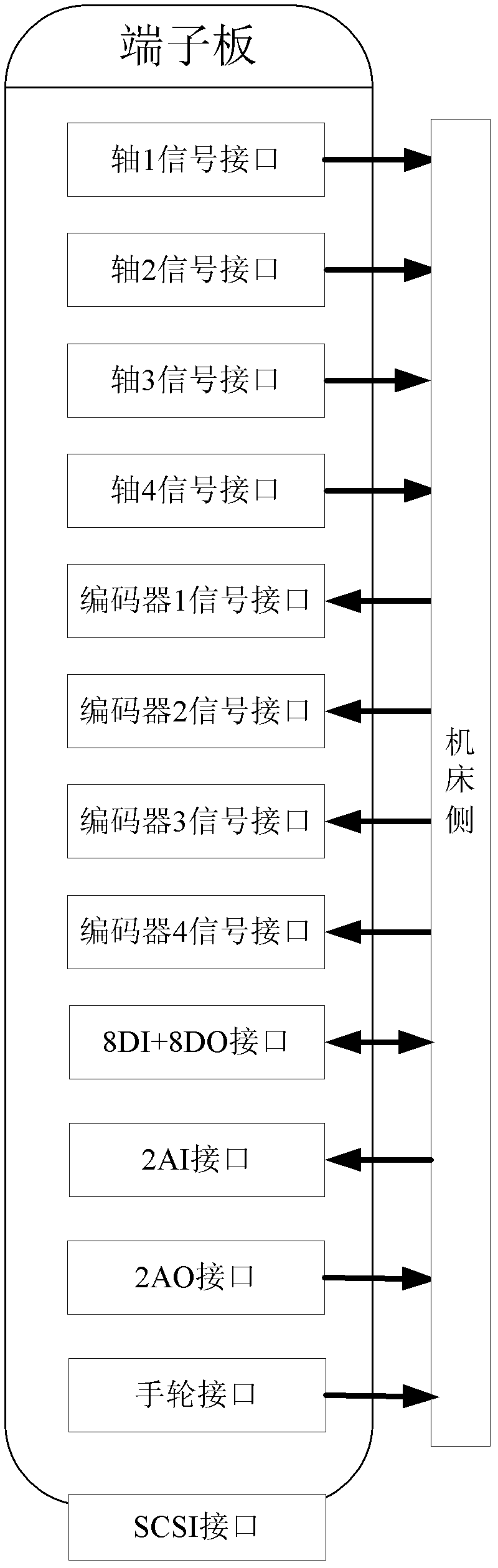

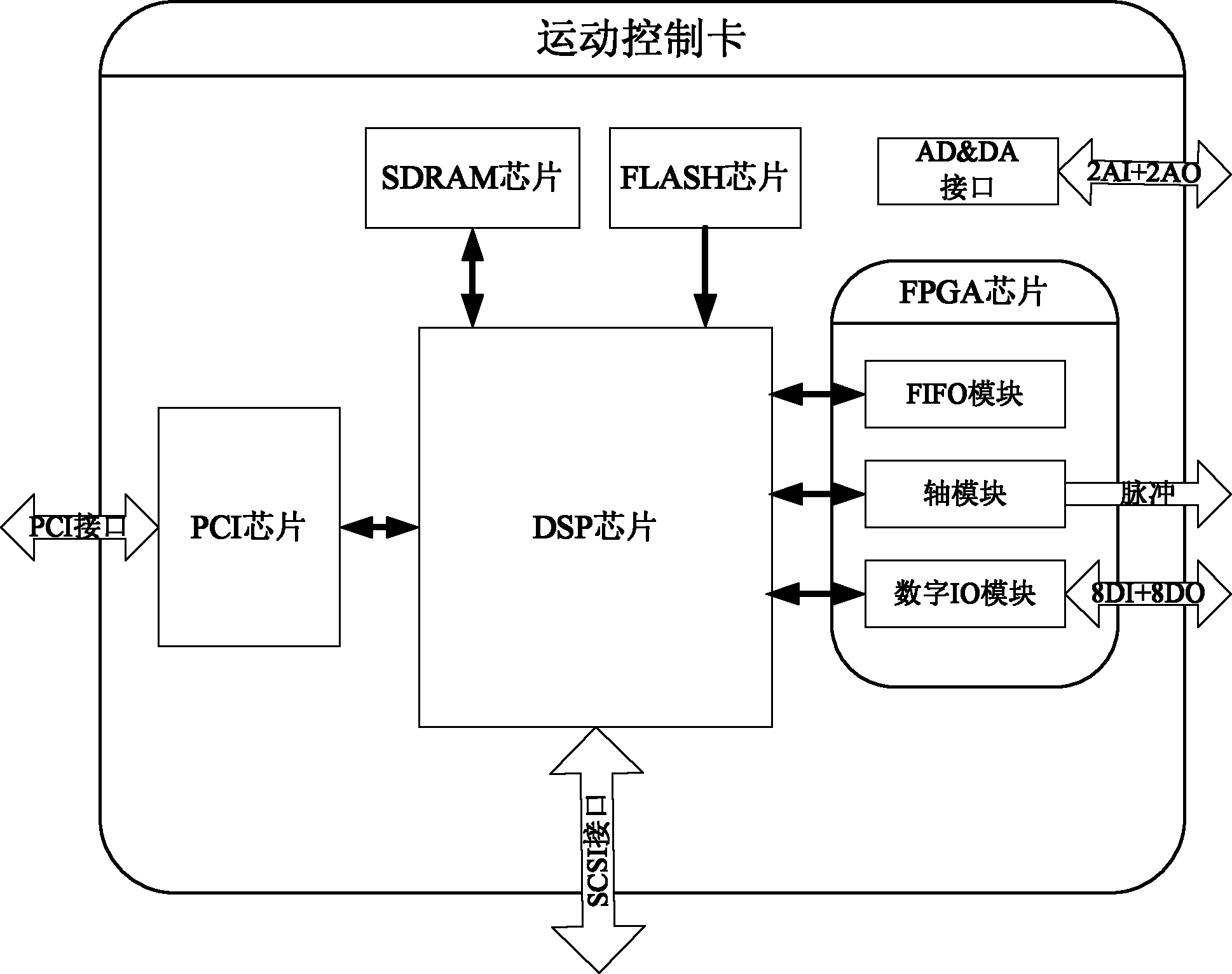

[0019] like figure 1 , figure 2 As shown, the control system of the end face knife grinder of the present invention includes an industrial computer, a motion control card, and a terminal board. The industrial computer and the motion control card are connected through a PCI interface, and the motion control card and the terminal board are connected through a SCSI interface; the PCI interface is 32-bit PCI bus interface.

[0020] The terminal board includes 4 servo / stepper motor control signal interfaces, 4 encoder signal interfaces, 8 digital output interfaces, 8 digital input interfaces, 2 analog output interfaces, and 2 analog input interfaces , 1 handwheel control signal interface; the SCSI interface of the terminal board is connected with the SCSI interface of the motion control card.

[0021] The 4-way servo / stepping motor control signal interfaces are respectively ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap