Surface-mounted fuser

A surface mount, fuse technology, applied in the high-voltage field, can solve the problems of limited fuse shape design, difficulty in mass production, small and easily broken fuses, etc. Short cycle time and good welding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

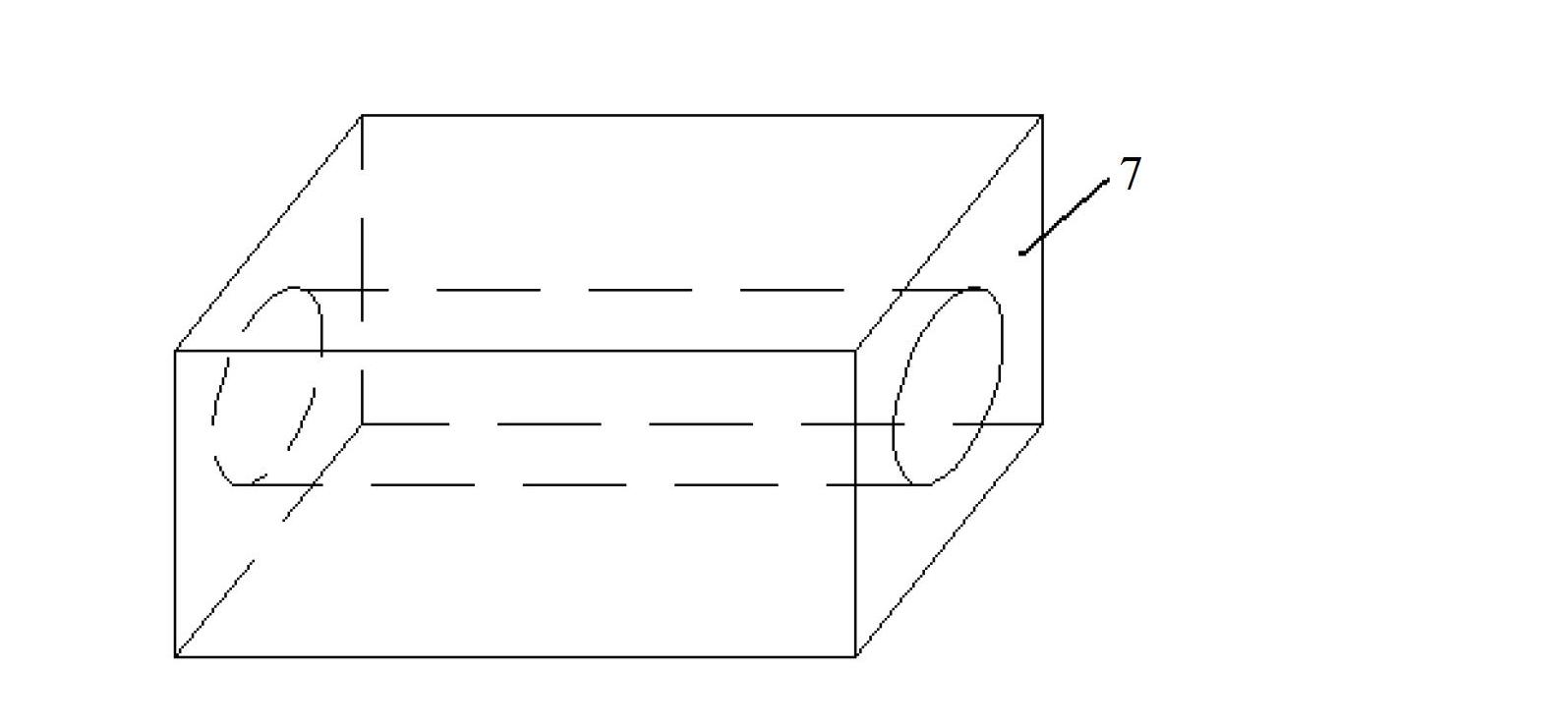

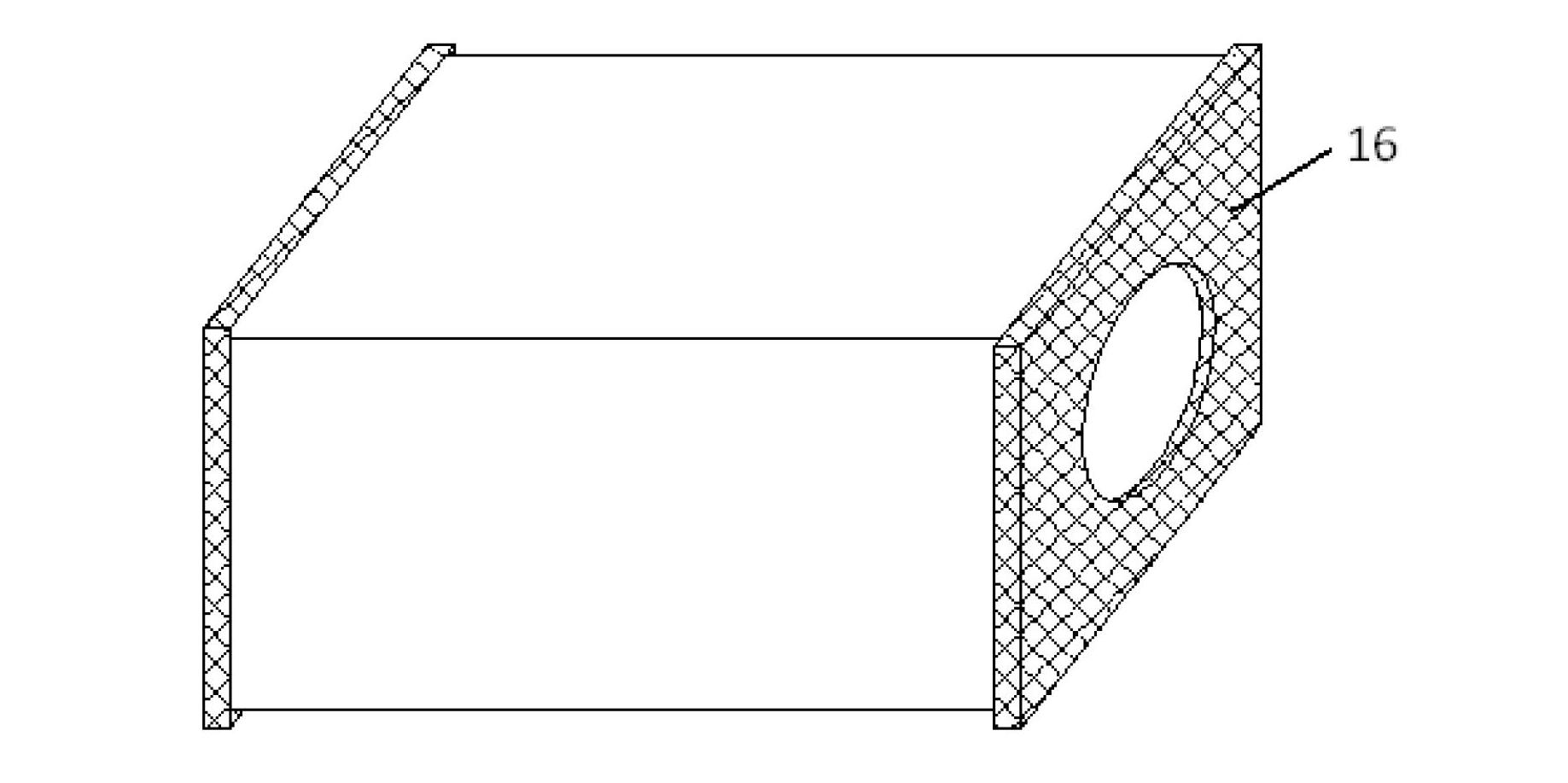

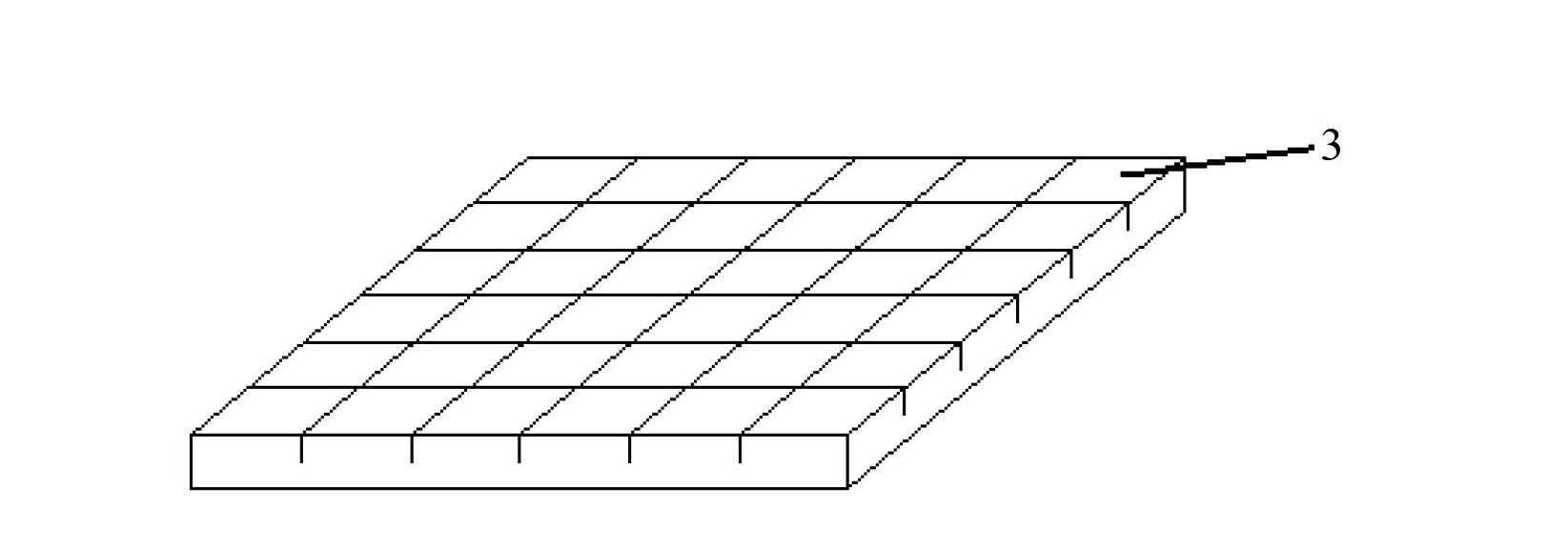

[0036] Example: A surface mount fuse, as attached Figure 1-13 As shown, it includes a fuse chip 1. This fuse chip 1 is mainly composed of two terminal electrodes 2, a ceramic substrate 3, a melt layer 4, an arc-extinguishing glass layer 5 and a protective layer 15. The melt layer 4 is located on the ceramic substrate. On the upper surface of the sheet 3, the two terminal electrodes 2 are located on both sides of the melt layer 4 and are electrically connected to the melt layer 4, and the arc-extinguishing glass layer 5 covers the melt layer 4 and the terminal electrodes 2 The area near the melt layer also includes a fuse body 7 with a circular through hole 6 in the middle, the fuse chip 1 is located in the circular through hole 6 of the fuse body 7, and two metal covers 8 are respectively located in the Two ends of the fuse body 7 are cut off and the circular through hole 6 is covered to form a closed cavity, and the terminal electrode 2 is electrically connected to the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com