High fidelity transistor audio power amplifying device

A technology of amplifying device and audio power, applied in the field of electronics, can solve the problems of lack of mellow feeling and sweetness, less sound detail, poor bass and treble listening feeling, etc., to achieve broad market application prospects, easy production and power utilization high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

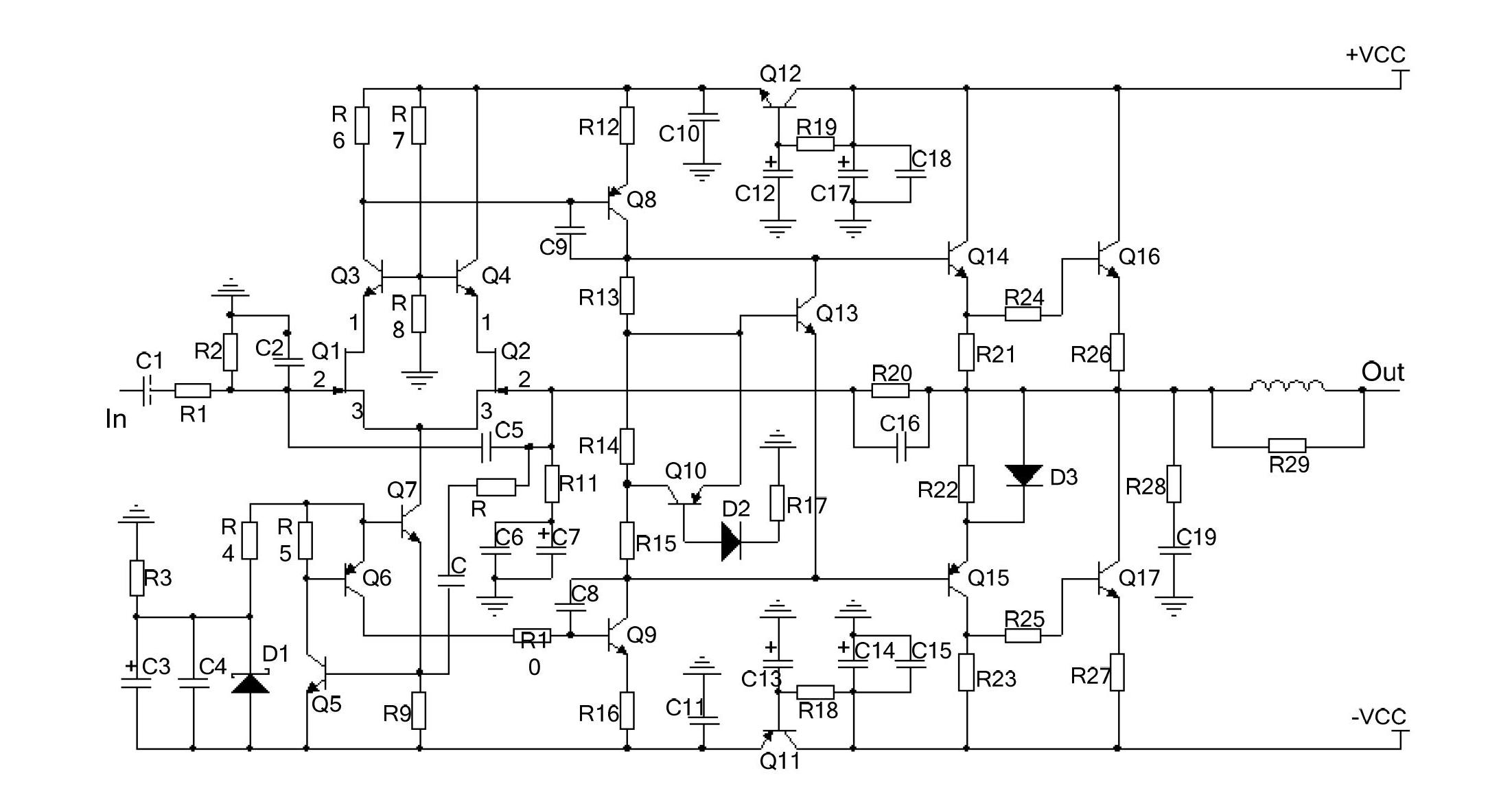

[0084] The key of the present invention is to convert the input audio signal into an audio differential mode signal. The audio differential mode signal refers to the composite signal of the audio signal of the sources of the two field effect tubes in the field effect tubes connected by two sources, and then It is converted into a normal audio signal, so that the entire amplifying device forms a real circuit push-pull working state, thereby obtaining an audio signal with beautiful sound quality.

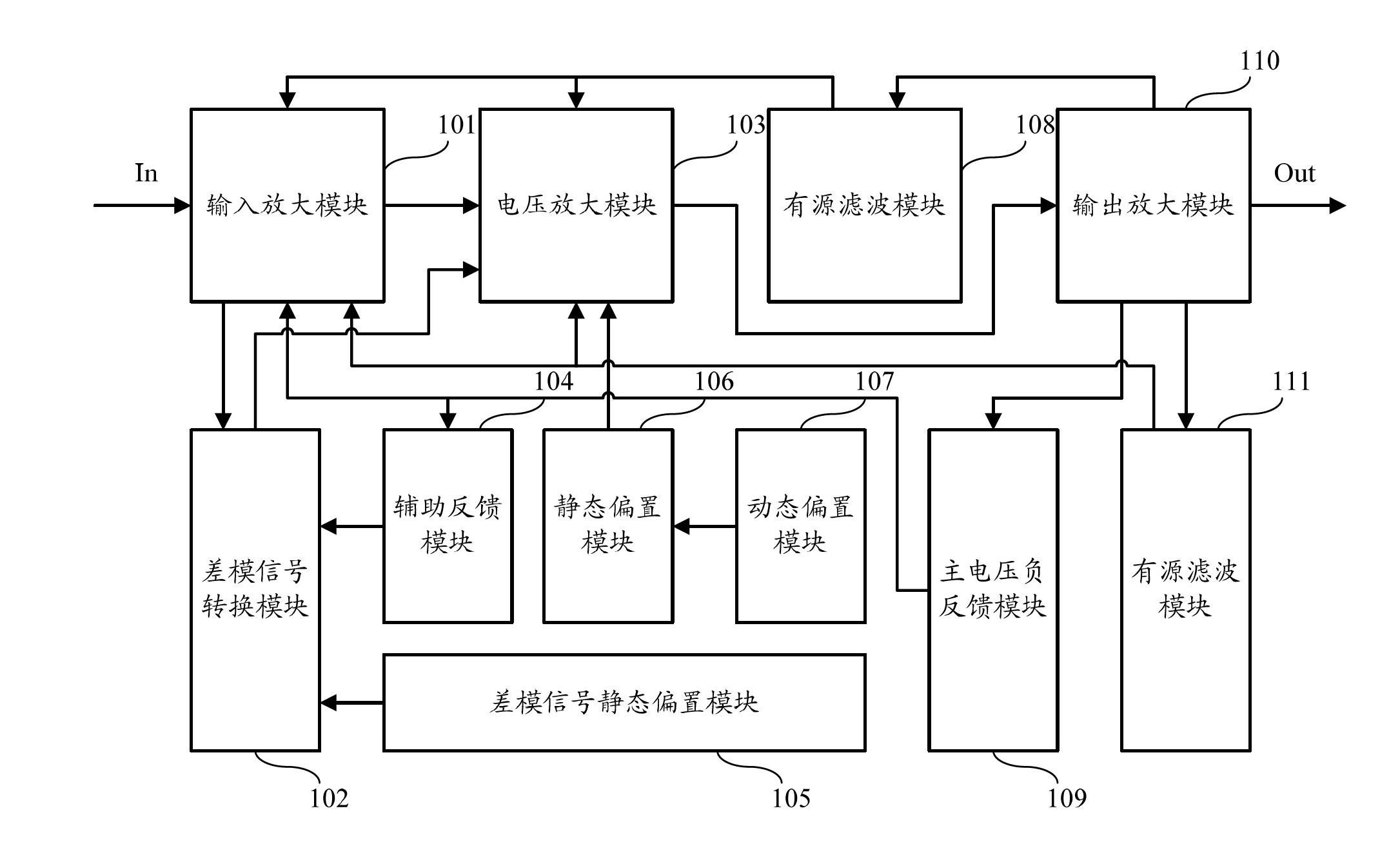

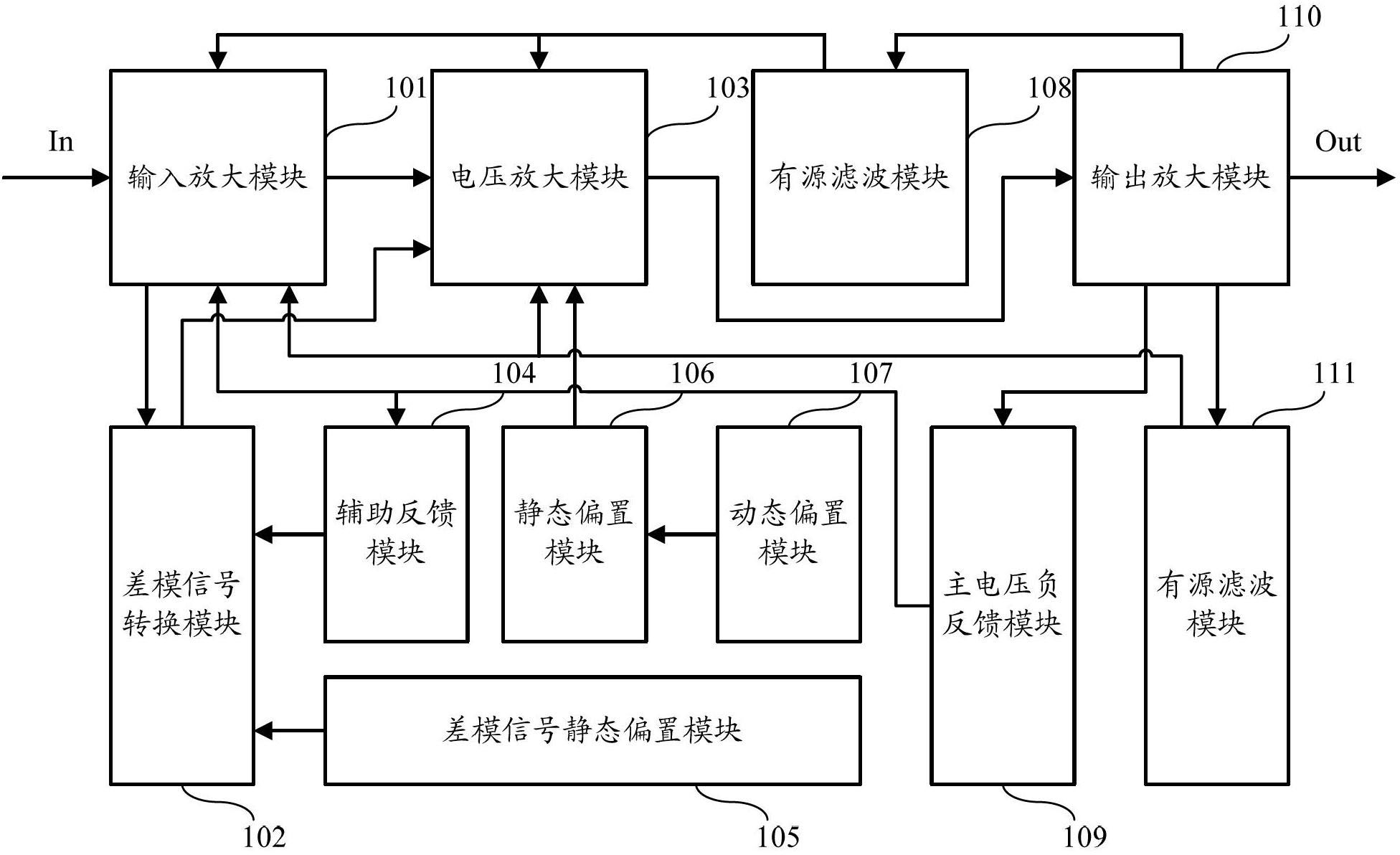

[0085] figure 1 It is a schematic structural diagram of a high-fidelity transistor audio power amplification device according to an embodiment of the present invention, as figure 1 As shown, the device includes:

[0086] The input amplification module 101 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com