Wiring connection methods and functional devices

A technology for functional devices and connection methods, applied in connection, circuit/collector parts, semiconductor devices, etc., can solve problems such as yield deterioration, and achieve the effects of improving yield, efficient manufacturing, and reliable electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

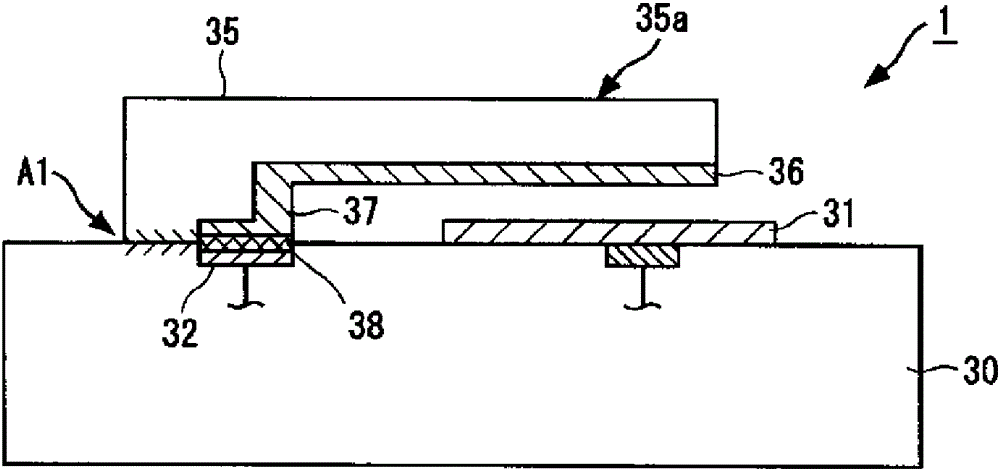

[0072] Figure 9 It is a figure which shows the process of the wiring connection method performed in Example 1. The first substrate 70 and the second substrate 75 are fabricated by the following method.

[0073] With regard to the first substrate 70, steps are locally formed on the silicon substrate 71, and after an oxide film is formed by CVD, the oxide film on the surface to be bonded to the second substrate 75 is wet-etched, and on the remaining oxide film 72 A circuit was formed, and a Ti layer 73 a of 100 nm and a Cu layer 73 b of 600 nm were sequentially laminated as the connection electrode portion 73 . The surface of the electrode pad serving as the connection electrode portion 73 was lowered by 300 nm than the bonding surface.

[0074] In the second substrate 75 , a Cr layer 77 a and a Cu layer 77 b are sequentially stacked on the through wiring 76 a of the LTCC substrate 76 as the connection electrode portion 77 , and a Sn layer is stacked as the metal layer 78 . ...

Embodiment 2

[0087] In Example 2, the height of the Sn layer as the metal layer 78 from the bonding surface of the LTCC substrate 76 was 1000 nm. Other than that, it is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com