Casting method of motor casing

A technology of motor housing and master mold, applied in casting molding equipment, casting mold, casting mold composition, etc., can solve the problems of unreasonable runner structure design and unsatisfactory casting effect, etc., to improve casting quality and improve Casting quality, the effect of reducing loose shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0021] Example.

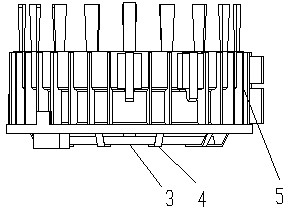

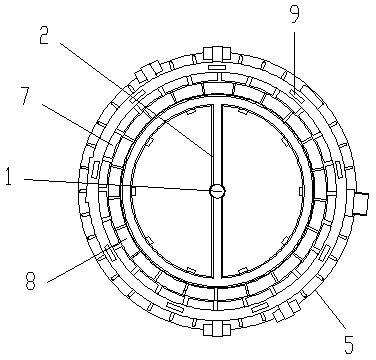

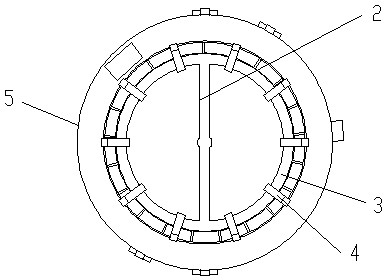

[0022] Such as Figure 1 to Figure 6 As shown, the casting method of the motor housing in this embodiment uses a runner structure and a master mold 5 for casting. The runner structure includes a sprue 1, a runner 2, a ring runner 3 and 9-11 internal Runner 4.

[0023] The runner 2 is located in the annular region of the runner 3 , both ends of the runner 2 are connected to the runner 3 , and the runner 2 is located at the diameter of the runner 3 .

[0024] The lower end of the sprue 1 is connected to the middle of the runner 2, the sprue 1 and the runner 2 are perpendicular to each other, and the axis of the sprue 1 and the axis of the female mold 5 are on the same straight line.

[0025] The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com