Cutter with function of decoupling temperature of turning area

A cutting tool and functional technology, applied in the field of cutting tools with temperature decoupling function in the turning area, can solve the problems of high difficulty in arranging galvanic couples, large measurement range, short response time, etc., and achieve high reliability of operation and measurement results, and anti-interference The effect of strong ability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

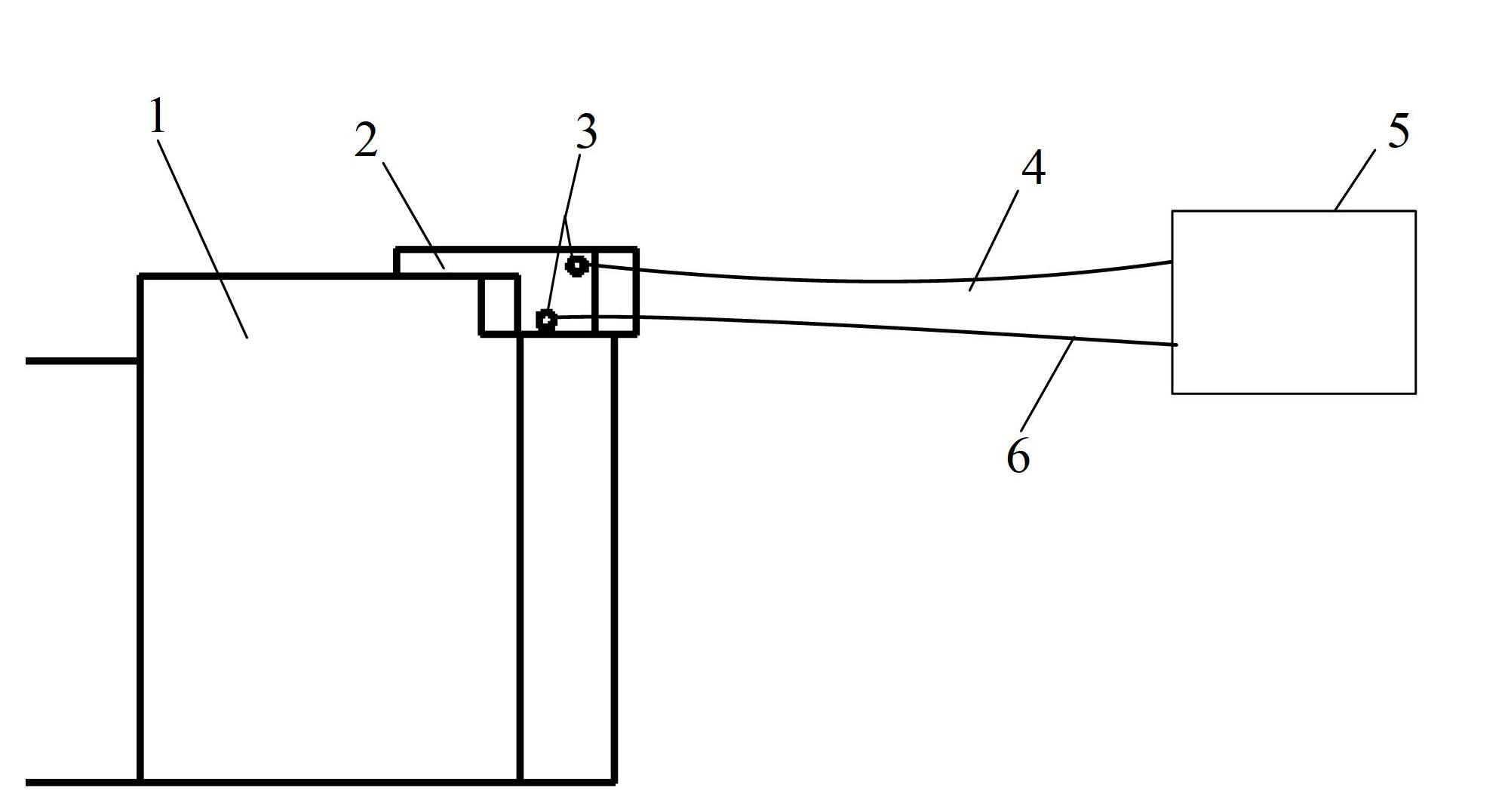

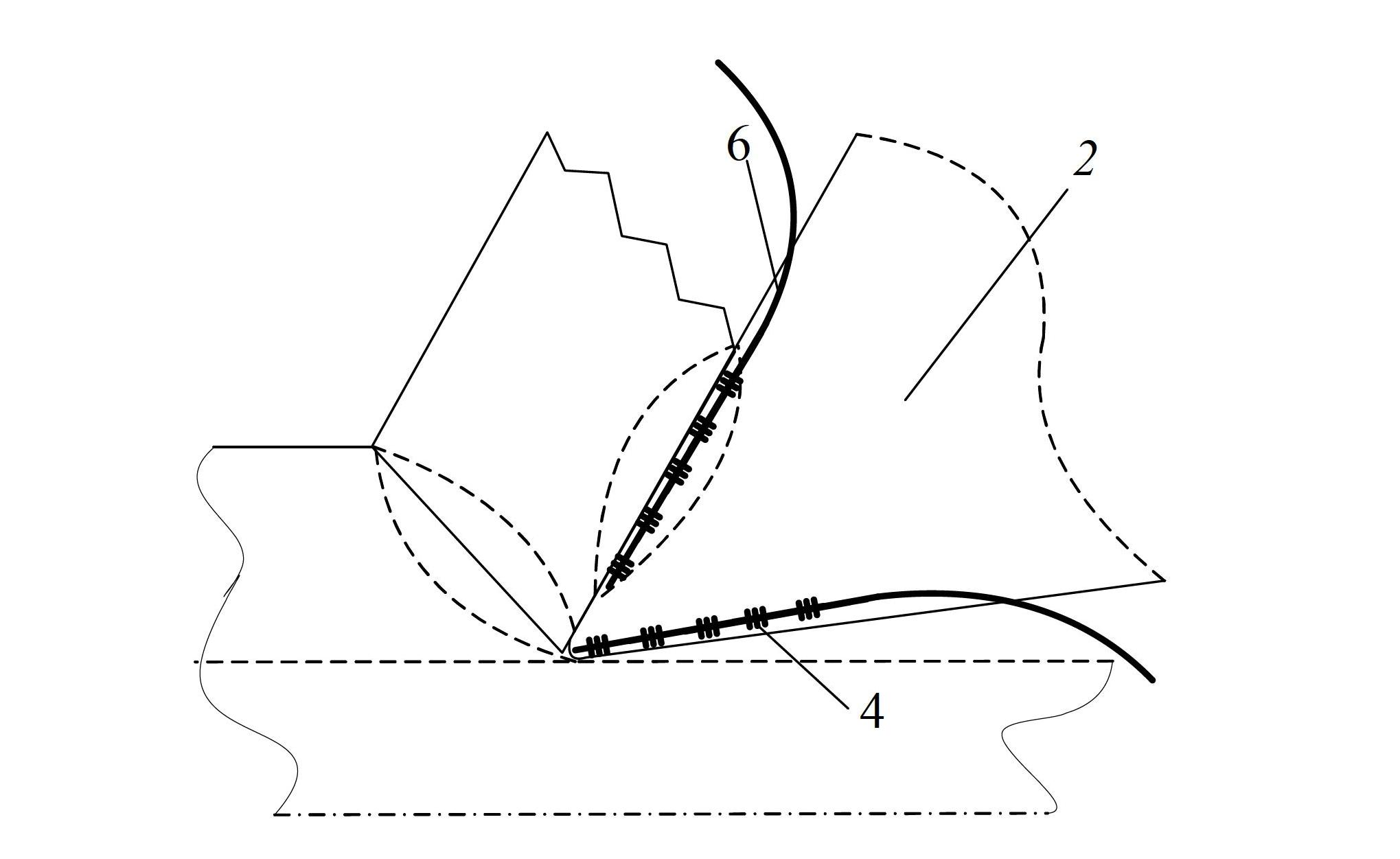

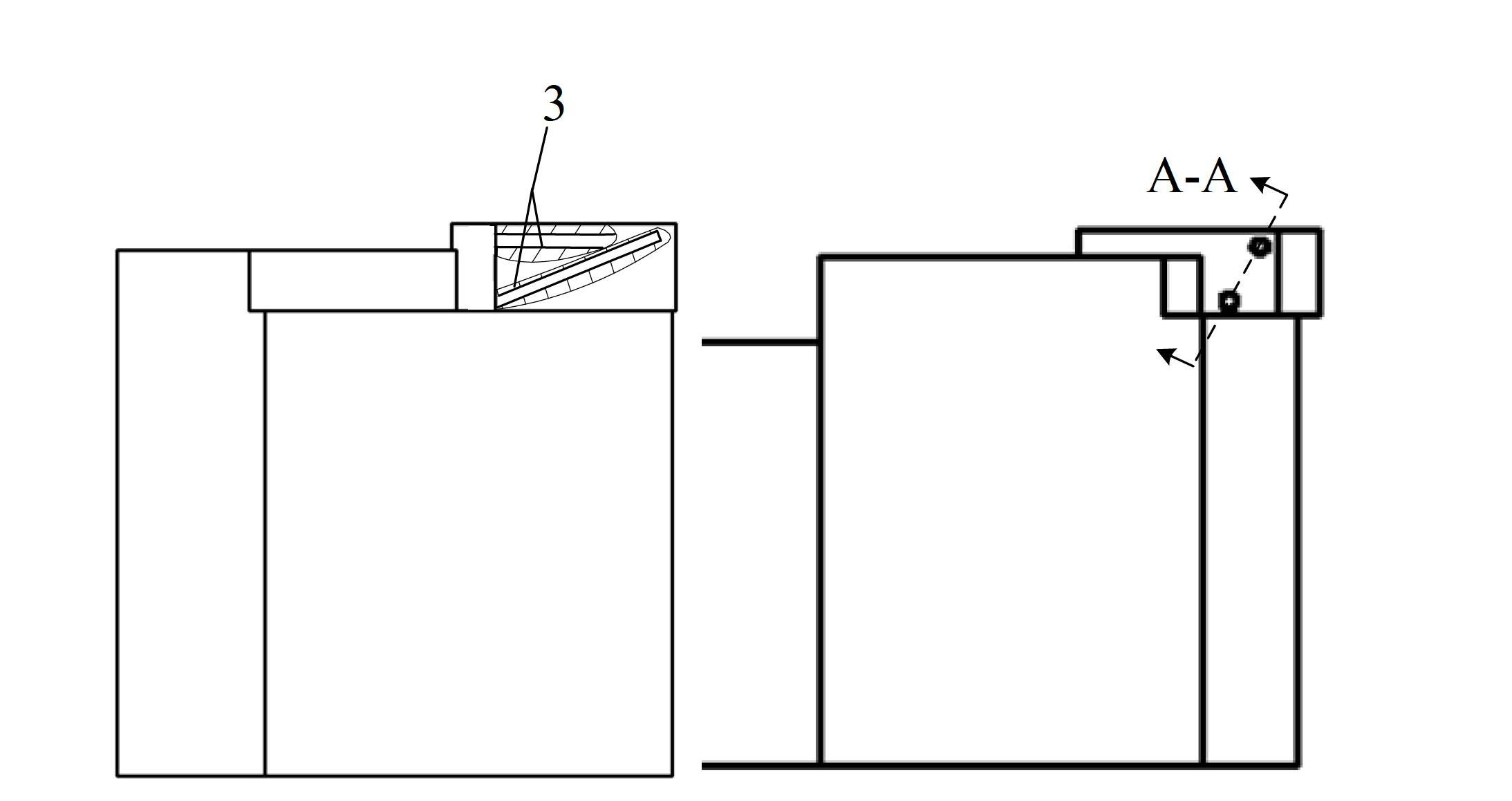

[0015] Such as figure 1 As shown, the turning tool bar 1 is equipped with a machine clamp blade 2 for turning, and a micro blind hole 3 is opened on the machine clamp blade for turning. The first and second high-temperature optical fiber gratings 4 and 6 respectively test the first and second heat source areas. For the temperature distribution, the high-temperature fiber grating 4 tests the heat generated by the first heat source (shear band heat source), and the high-temperature fiber Bragg grating 6 tests the second heat source (the heat source on the chip contact surface). Generally speaking, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com