Concrete mixer tank and mixing blade assembly welding tooling and welding process

A technology of stirring blades and welding tooling, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of heavy blade weight, harsh working environment, poor ventilation effect of the tank, etc., and improve the stirring performance and discharge capacity. , The overall blade surface is smooth and the weld is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

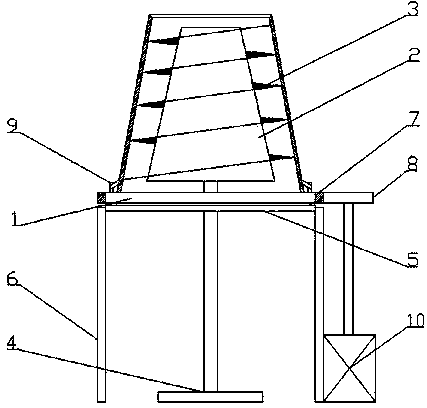

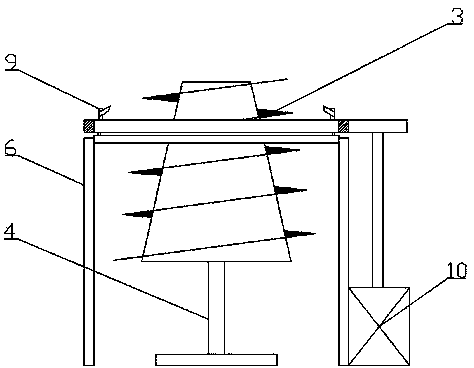

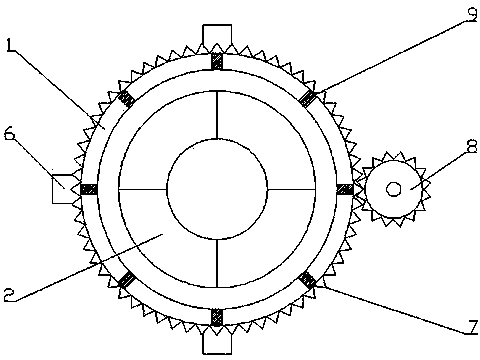

[0027] Use the above-mentioned welding equipment to realize the preliminary assembly and welding of the mixing blade and the tank body of the mixer truck, and prepare the segmented tank body and the corresponding inner cone male mold:

[0028] (a), use the hydraulic lifting device 4 to adjust the position of the inner cone male mold 2, so that the inner cone male mold 2 is on the rotating base plate 1, and then attach the shaped segmented spiral blade to the blade mother plate 3, Then the segmented spiral blades are butt welded together, and the welding operation method of single-sided welding and double-sided forming is adopted during welding. Welding, an operation method to ensure that both sides of the groove can get double-sided formed welds after welding. CO2 is used for welding. 2 For gas shielded welding, the welding wire is ER50-6 welding wire with a diameter of 1.2mm, the welding voltage is 24V, the welding current is 260A, the welding speed is 50cm / min, the gas flow ...

Embodiment 2

[0032] Use the above-mentioned welding equipment to realize the preliminary assembly and welding of the mixing blade and the tank body of the mixer truck, and prepare the segmented tank body and the corresponding inner cone male mold:

[0033] (a), use the hydraulic lifting device 4 to adjust the position of the inner cone male mold 2, so that the inner cone male mold 2 is on the rotating base plate 1, and then attach the shaped segmented spiral blade to the blade mother plate 3, Then the segmented spiral blades are butt welded together, and the welding operation method of single-sided welding and double-sided forming is adopted during welding. Welding, an operation method to ensure that both sides of the groove can get double-sided formed welds after welding. CO2 is used for welding. 2 For gas shielded welding, the welding wire is ER50-6 welding wire with a diameter of 1.2mm, the welding voltage is 26V, the welding current is 230A, the welding speed is 40cm / min, the gas flow ...

Embodiment 3

[0037] Use the above-mentioned welding equipment to realize the preliminary assembly and welding of the mixing blade and the tank body of the mixer truck, and prepare the segmented tank body and the corresponding inner cone male mold:

[0038] (a), use the hydraulic lifting device 4 to adjust the position of the inner cone male mold 2, so that the inner cone male mold 2 is on the rotating base plate 1, and then attach the shaped segmented spiral blade to the blade mother plate 3, Then the segmented spiral blades are butt welded together, and the welding operation method of single-sided welding and double-sided forming is adopted during welding. Welding, an operation method to ensure that both sides of the groove can get double-sided formed welds after welding. CO2 is used for welding. 2 For gas shielded welding, the welding wire is ER50-6 welding wire with a diameter of 1.2mm, the welding voltage is 28V, the welding current is 200A, the welding speed is 35cm / min, the gas flow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com