Cold ejection energy recovery device

An energy recovery device and energy recovery technology, applied in the field of engineering mechanics, can solve the problems of high rotational speed and instability, difficult to realize the coupling of energy storage and load, missing fighter planes, etc. The effect of a large degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

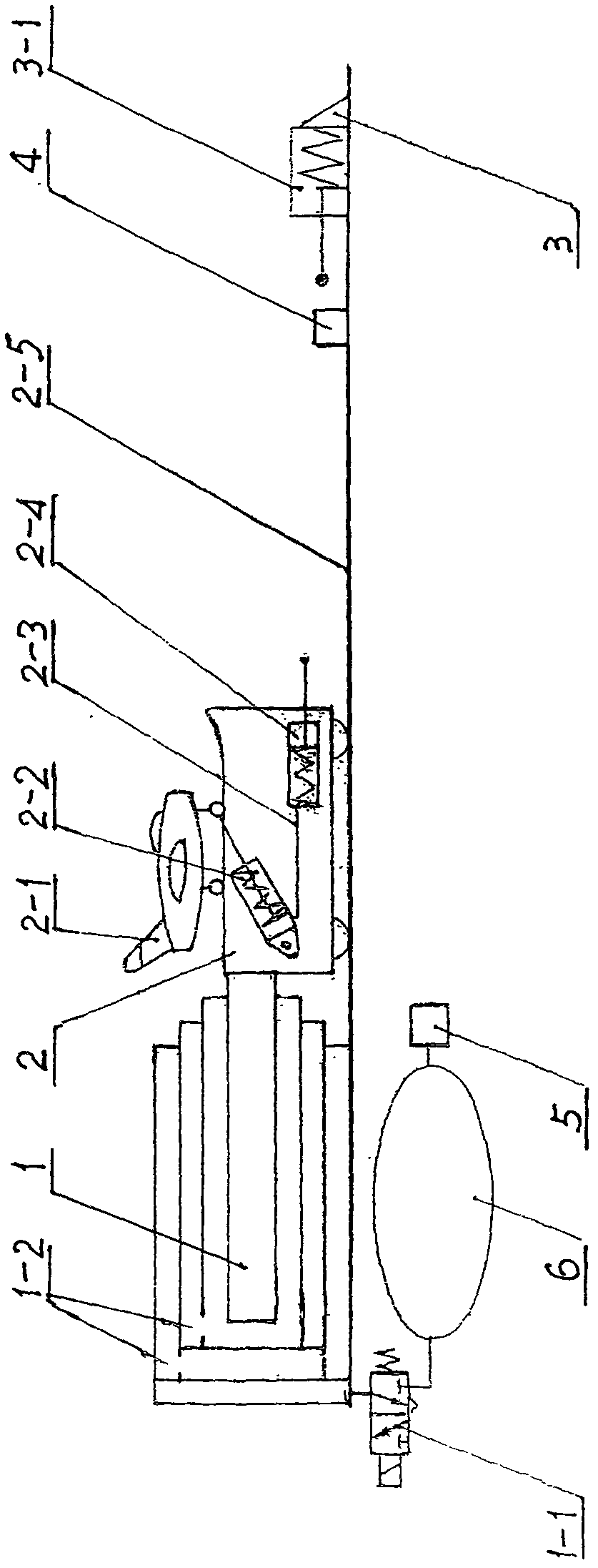

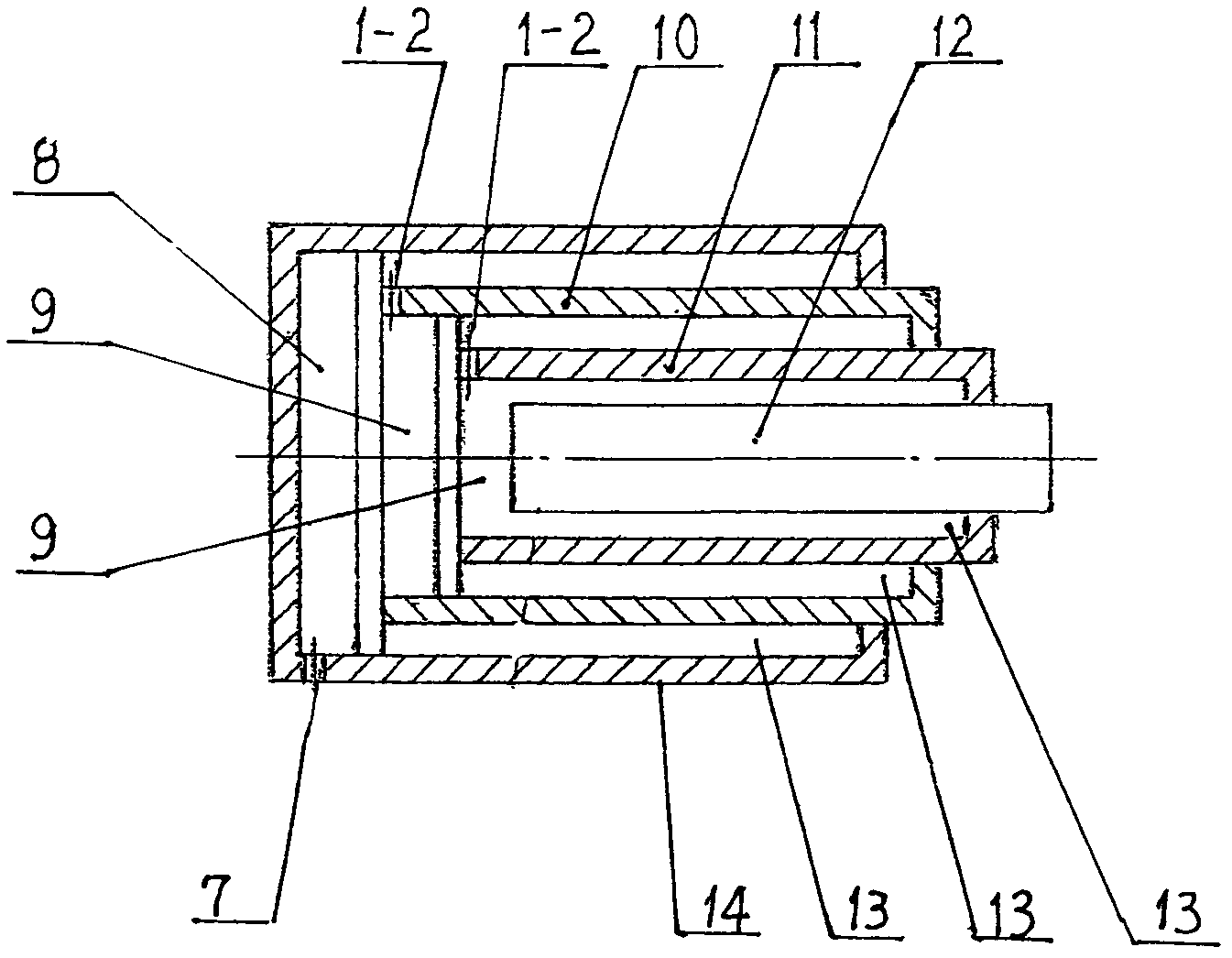

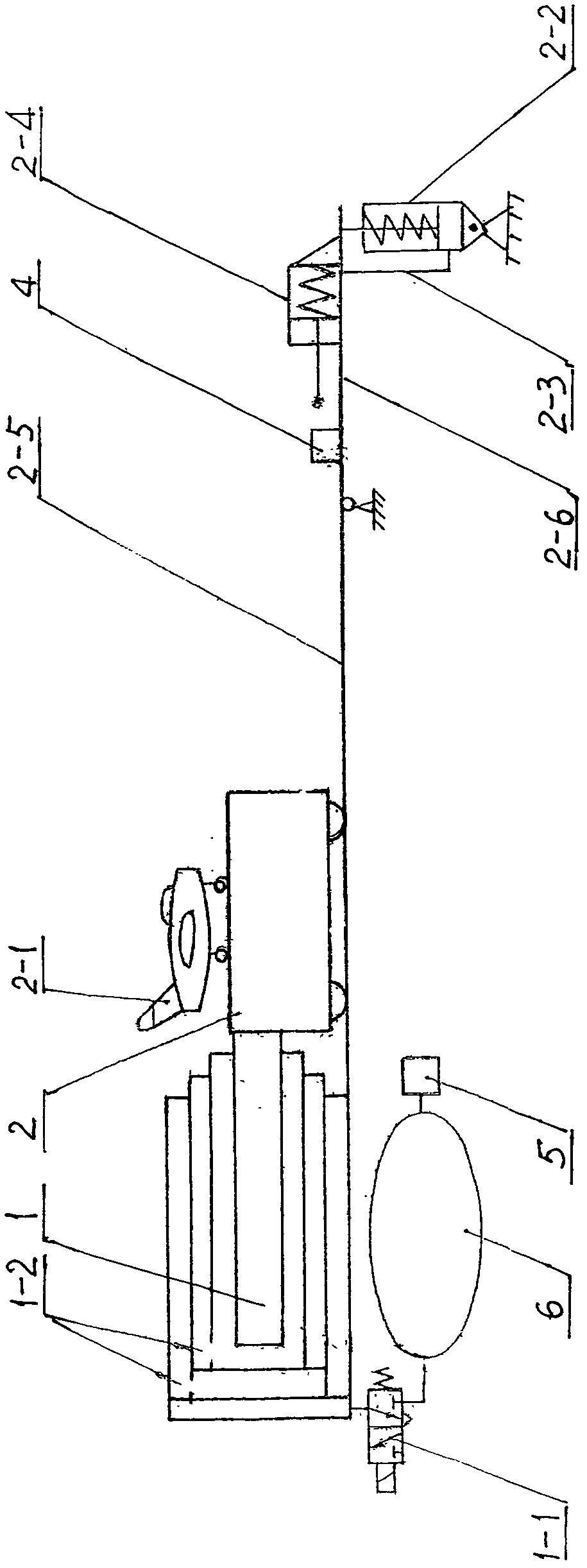

[0036] see figure 1 , figure 2 , In this embodiment 1, a three-stage gas-liquid fusion oil cylinder 1, a two-position three-way electromagnetic control valve 1-1, a high-energy gas source 5, a gas cylinder 6, an energy recovery pump 2-4, a jumping cylinder 2-2 and a limit A buffer spring is provided in the oil blocking cylinder 3, and a damping hole 3-1 is provided in the limiting oil blocking cylinder 3. Usually, according to the ejection conditions given by the superior, the CNC high-energy gas source 5 stores the required high-energy gas in the gas cylinder 6, and then stops and stands by. In its cold state with its mechanical fully closed, the catapult remains in a ready-to-fire state at all times. During wartime, under the cold condition with its machinery completely closed, it is possible to energize the two-position three-way electromagnetic control valve 1-1 and control part of the high-energy gas of its gas cylinder 6 to enter the third-stage gas-liquid fusion thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com