Method for preparing spherical wolfram carbide powder

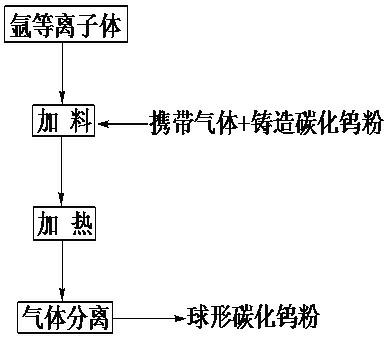

A technology of tungsten carbide powder and tungsten carbide, which is applied in the field of preparing spherical tungsten carbide powder, which can solve the problems of long process flow, low production efficiency, and difficulty in tungsten carbide dispersion control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

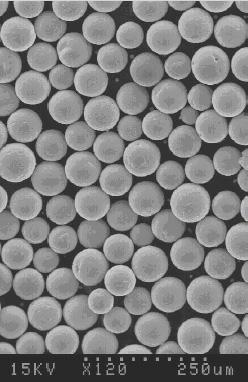

[0027] Example 1: The average particle size of raw material casting tungsten carbide powder is 50 μm, the input power of argon plasma during the spheroidization process is 30 kW, and the negative pressure of the system is maintained at 130 mm Hg. The main plasma working gas argon and the auxiliary gas hydrogen pressure are both 0.5MPa. The pressure of the carrying gas nitrogen is 0.6MPa, the flow rate of the carrying gas is 600L / h, and the feeding rate of tungsten carbide powder is 40g / min.

Embodiment 2

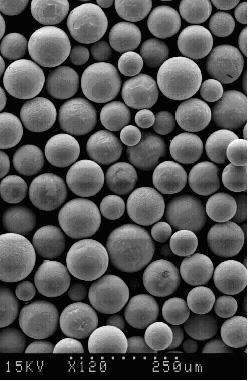

[0028] Example 2: The average particle size of raw material casting tungsten carbide powder is 70 μm, the input power of argon plasma during the spheroidization process is 35 kW, and the negative pressure of the system is maintained at 180 mm Hg. The main plasma working gas argon and auxiliary gas hydrogen pressure are 0.6MPa. The pressure of the carrying gas nitrogen is 0.75MPa, the flow rate of the carrying gas is 700L / h, and the feeding rate of tungsten carbide powder is 35g / min).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com