Preparation method for high-purity ammonium paratungstate

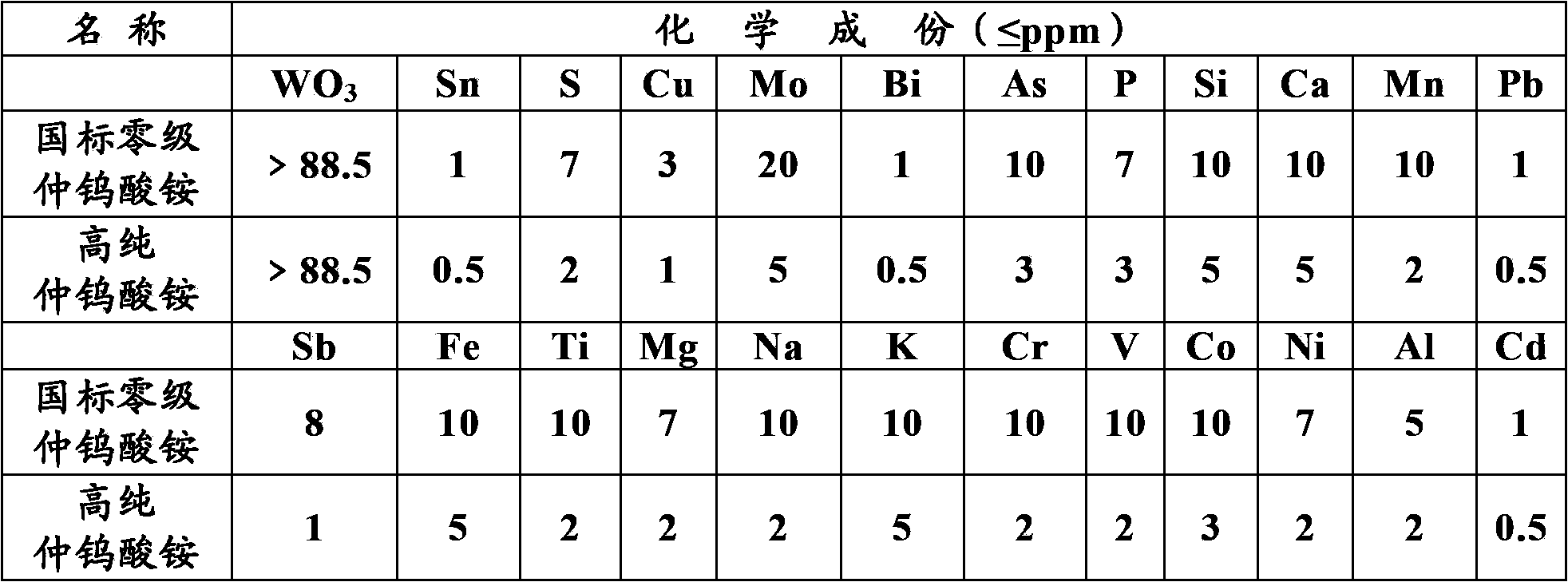

A technology of pure ammonium paratungstate and ammonium tungstate, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve problems such as low conversion rate, poor effect, and ineffective removal of impurities, so as to improve recovery rate and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

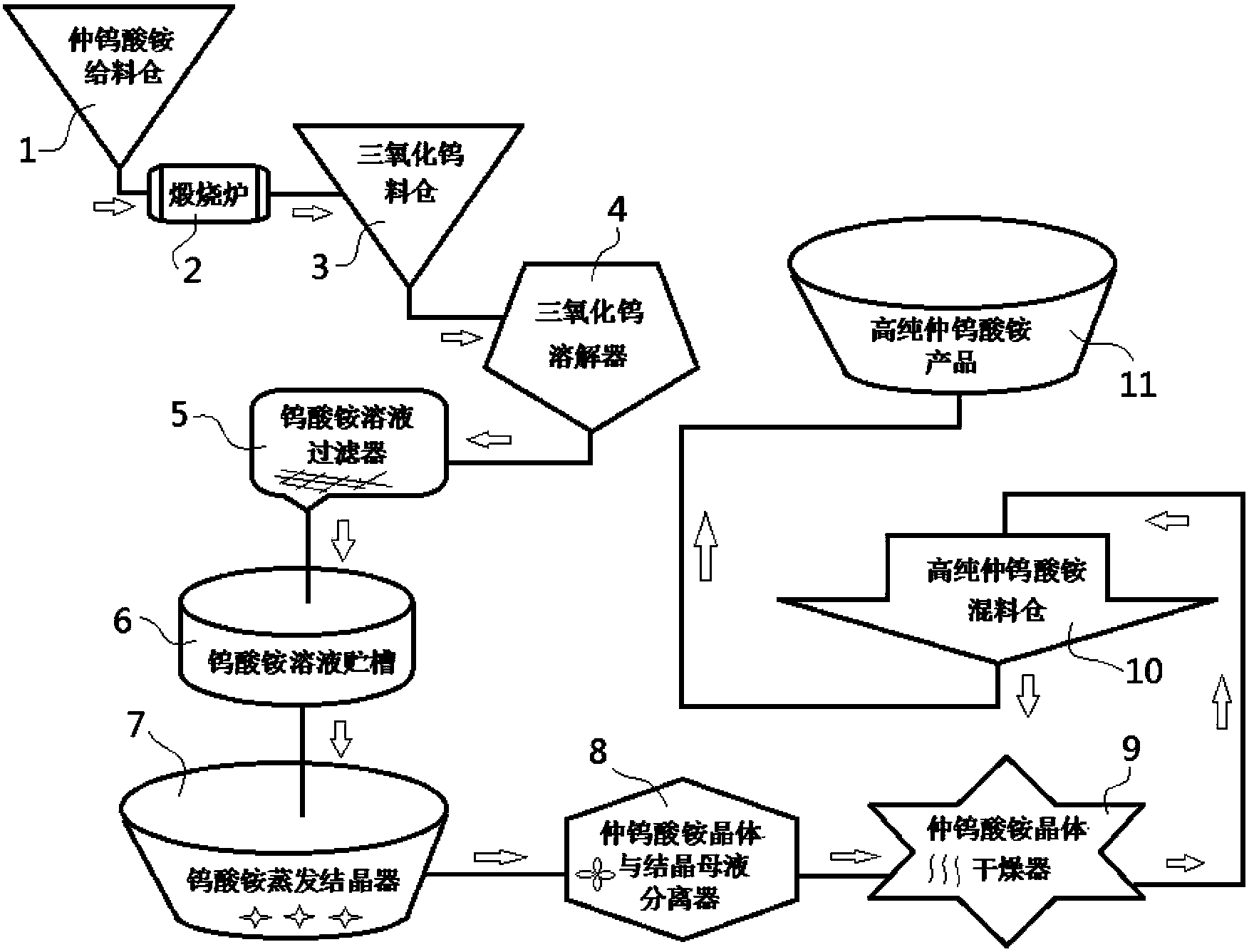

Method used

Image

Examples

Embodiment 1

[0038] 1. The process of APT calcining to generate tungsten trioxide. Put the APT into the feeding bin, send the APT into the rotary furnace at a constant speed through the screw feeder, control the temperature and atmosphere in the rotary furnace, the feed rate is 150kg / h, and the calcination temperature is 550°C for the first zone and 640°C for the second zone. Three bands 680°C. After being calcined in a rotary furnace, the conversion rate of APT into tungsten trioxide reaches 98.85%.

[0039] 2. During the dissolving process of ammonium tungsten trioxide, the temperature of 150g / l ammonia solution is controlled at 95°C, the liquid-solid ratio is controlled at 3:1ml / g, and tungsten trioxide is added while stirring, and the reaction time is 1.5h to obtain ammonium tungstate solution. and filter.

[0040] 3. After the ammonium tungstate solution is filtered, it is measured into the evaporative crystallization pot for evaporative crystallization, and the evaporative crystall...

Embodiment 2

[0043]1. The process of APT calcining to generate tungsten trioxide. Put the APT into the feed bin, send the APT into the rotary furnace at a constant speed through the screw feeder, control the temperature and atmosphere in the rotary furnace, the feed rate is 160kg / h, and the calcination temperature is 560°C in the first zone and 650 in the second zone. ℃, three bands 690 ℃. After being calcined in a rotary furnace, the conversion rate of APT into tungsten trioxide reaches 99.05%.

[0044] 2. The ammonia tungsten trioxide dissolution process, the concentration of 70g / l ammonia solution is controlled at 100°C, the liquid-solid ratio is controlled at 4:1ml / g, adding tungsten trioxide, stirring, and the reaction time is 2 hours to obtain ammonium tungstate solution, and filtered.

[0045] 3. After the ammonium tungstate solution is filtered, it is measured into the evaporative crystallization pot for evaporative crystallization, and the evaporative crystallization steam is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com