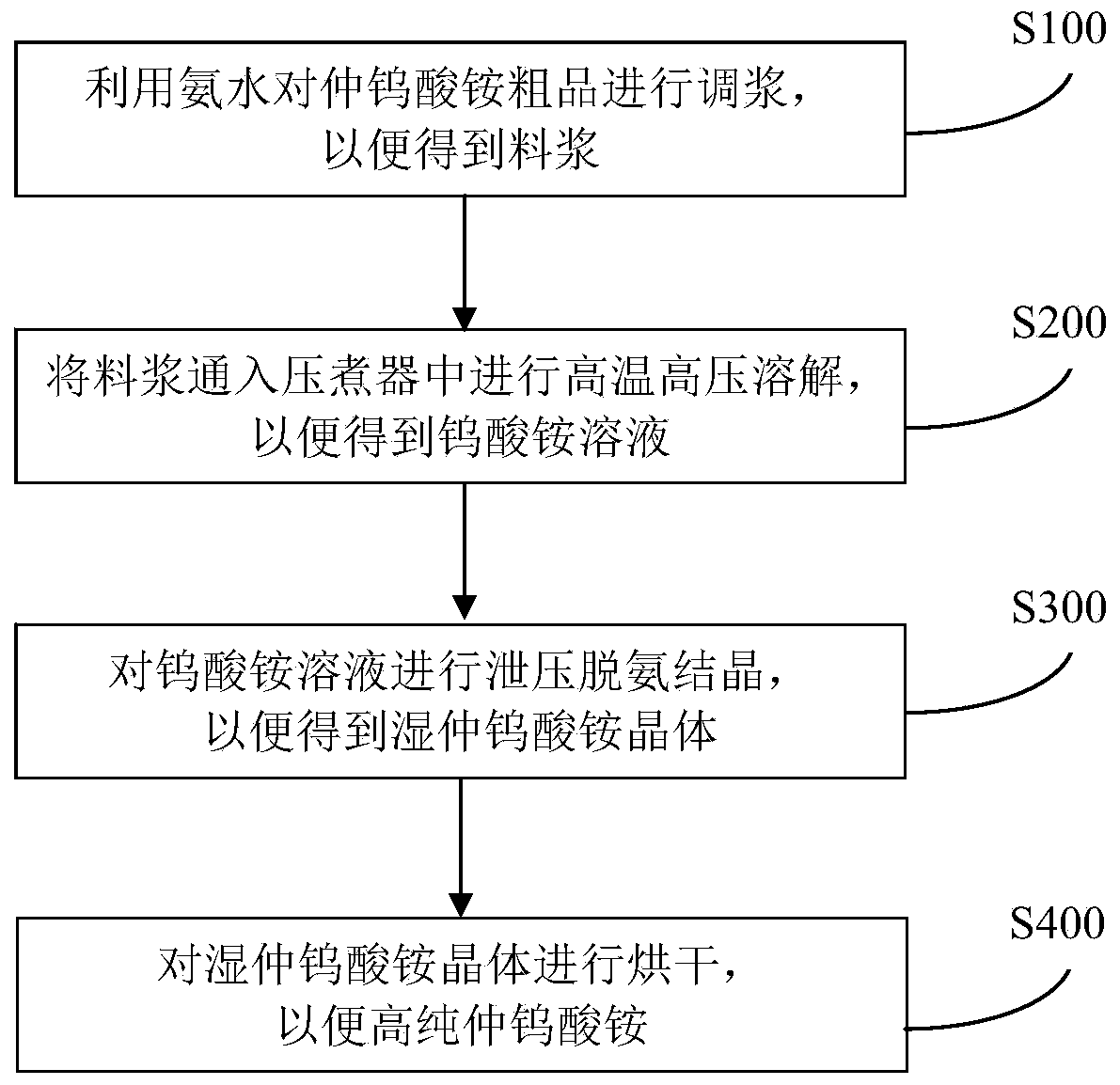

Method for preparing high-purity ammonium paratungstate

A technology of pure ammonium paratungstate and ammonium paratungstate, which is applied in the field of preparing high-purity ammonium paratungstate, can solve the problems of high pressure of wastewater treatment, many equipment required, and large liquid volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. The raw material is national standard 0 grade APT, and the total content of detected impurities is 165.4ppm. Add 12m to the mixing tank 3 Ammonia water, the concentration of ammonia water is 140g / l, and 3428.6kg of raw materials are slowly put into the mixing process for slurry mixing.

[0046] 2. After the feeding is completed, the pressure cooker is turned on and stirred, and the feed liquid is added to the 15m 3 In the pressure cooker, the jacket is heated with steam until the temperature is 140° C., and the pressure is 0.6 MPa at this time. After the temperature is reached, the heat preservation and pressure are kept for 3 hours.

[0047] 3. After heat preservation and pressure keeping, open the exhaust valve of the autoclave for pressure relief and deamination, adjust the opening of the exhaust valve to control the pressure relief time for 1 hour, and then cool to 60°C to stop cooling and filter to obtain wet ammonium paratungstate crystals and Mother liquor, ...

Embodiment 2

[0051] 1. The raw material is unqualified APT in the production process, and the total content of impurities detected is 300ppm. Add 12m to the mixing tank 3 Ammonia water, the concentration of ammonia water is 115g / l, and 3000kg of raw materials are slowly put into the slurry during the stirring process.

[0052] 2. After the feeding is completed, the pressure cooker is turned on and stirred, and the feed liquid is added to the 15m 3 In the autoclave, the jacket is heated with steam until the temperature is 125°C, and the pressure is 0.51MPa at this time. After the temperature is reached, the reaction is carried out with heat preservation and pressure for 1 hour.

[0053] 3. After heat preservation and pressure keeping, open the steam exhaust valve of the autoclave for pressure relief and deamination, adjust the opening of the steam exhaust valve to control the pressure relief time for 2 hours, and then cool to 50°C to stop cooling and filter to obtain wet ammonium paratungs...

Embodiment 3

[0057] 1. The raw material is unqualified APT in the production process, and the total detected impurity content is 233.8ppm. Add 12m to the mixing tank 3 Ammonia water, the concentration of ammonia water is 90g / l, and 3200kg of raw materials are slowly put into the slurry during the stirring process.

[0058] 2. After the feeding is completed, the pressure cooker is turned on and stirred, and the feed liquid is added to the 15m 3 In the autoclave, the jacket is heated with steam until the temperature is 110° C. and the pressure is 0.4 MPa at this time. After the temperature is reached, the heat preservation and pressure are kept for 2 hours.

[0059] 3. After heat preservation and pressure keeping, open the steam exhaust valve of the pressure cooker for pressure relief and deamination, adjust the opening of the steam exhaust valve to control the pressure relief time for 1.5 hours, and then cool to 55°C to stop cooling and filter to obtain wet ammonium paratungstate crystals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com