Self-sufficient water supply disc type solar sea water desalting device

A solar and disc technology, applied in the field of solar seawater desalination, can solve the problems of high investment and large energy consumption in seawater desalination technology, and achieve the effects of low heat source temperature, fast start-up speed and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

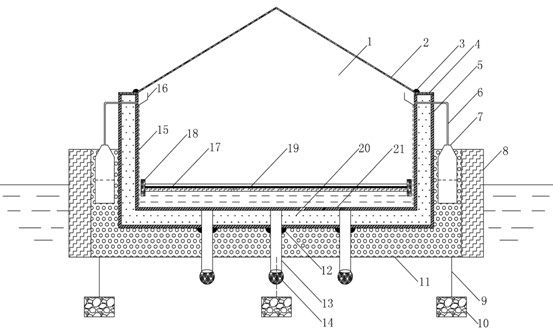

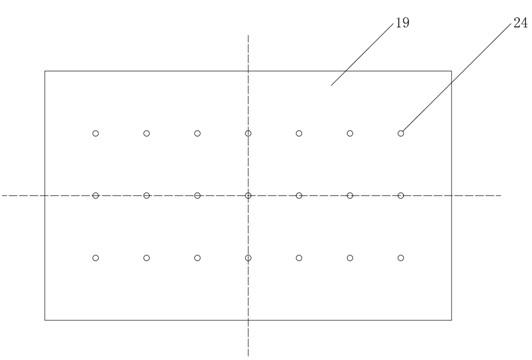

[0030]The size of the inner lining of the still is 1 m (length) × 1 m (width) × 0.3 m (height), the distance between the foam board and the walls around the inner lining of the still is 10 mm, and 30 holes are evenly opened on the heat-absorbing plate A small hole with a diameter of 1 mm adjusts the depth of seawater in the distillation chamber to 10 cm, adjusts the thickness of the seawater layer above the heat absorbing plate to 5 mm, adjusts the depth of seawater in the distillation chamber to 80 mm, and selectively absorbs the coating on the heat absorbing plate. The absorptivity of the layer is 0.9, and the emissivity is 0.3. The reflectivity of the reflective paint on the walls around the still lining is 0.8. Five small holes with a diameter of 2.5 mm are evenly seen on the inner lining of the still. The pore size is 15 mm, and the salinity of the seawater is 3.5%. A large number of experimental studies were carried out under sunny conditions in East China in late April. ...

Embodiment 2

[0032] The size of the inner lining of the still is 1 m (length) × 1 m (width) × 0.3 m (height), the distance between the foam board and the walls around the inner lining of the still is 10 mm, and 30 holes are evenly opened on the heat-absorbing plate A small hole with a diameter of 1 mm adjusts the depth of seawater in the distillation chamber to 10 cm, adjusts the thickness of the seawater layer above the heat absorbing plate to 5 mm, adjusts the depth of seawater in the distillation chamber to 80 mm, and selectively absorbs the coating on the heat absorbing plate. The absorptivity of the layer is 0.9, and the emissivity is 0.3. The reflectivity of the reflective paint on the walls around the still lining is 0.8. Nine small holes with a diameter of 2.5 mm are evenly seen on the inner lining surface of the still. The pore diameter is 15 mm, and the salinity of seawater is 3.5%. A large number of experimental studies were carried out under sunny conditions in East China in la...

Embodiment 3

[0034] The size of the inner lining of the still is 1 m (length) × 1 m (width) × 0.3 m (height), the distance between the foam board and the walls around the inner lining of the still is 10 mm, and 30 holes are evenly opened on the heat-absorbing plate A small hole with a diameter of 1 mm adjusts the depth of seawater in the distillation chamber to 15 cm, adjusts the thickness of the seawater layer above the heat absorbing plate to 5 mm, adjusts the depth of seawater in the distillation chamber to 80 mm, and selectively absorbs the coating on the heat absorbing plate. The absorptivity of the layer is 0.9, and the emissivity is 0.3. The reflectivity of the reflective paint on the walls around the still lining is 0.8. Nine small holes with a diameter of 2.5 mm are evenly seen on the inner lining surface of the still. The pore diameter is 15 mm, and the salinity of seawater is 3.5%. A large number of experimental studies were carried out under sunny conditions in East China in la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com