Wood filler earthworm biofilter and method for processing town residue sludge

A biological filter and excess sludge technology, applied in biological sludge treatment, biological water/sewage treatment, sludge treatment, etc., can solve the problems of poor connectivity, limit the density of earthworms, low porosity, etc. Porosity and connectivity, favorable for feeding activities, and the effect of increasing the density of the cast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

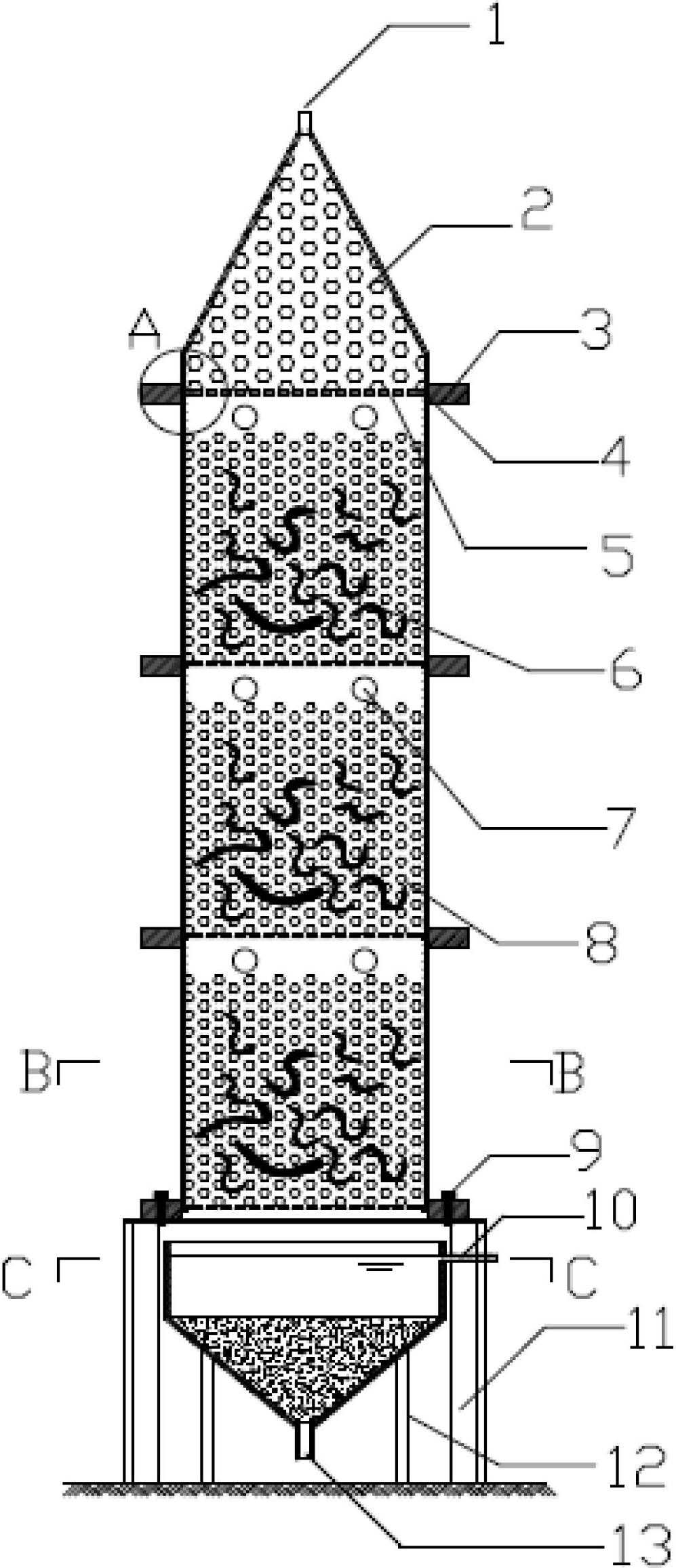

[0028] The present invention is described in detail in conjunction with the accompanying drawings.

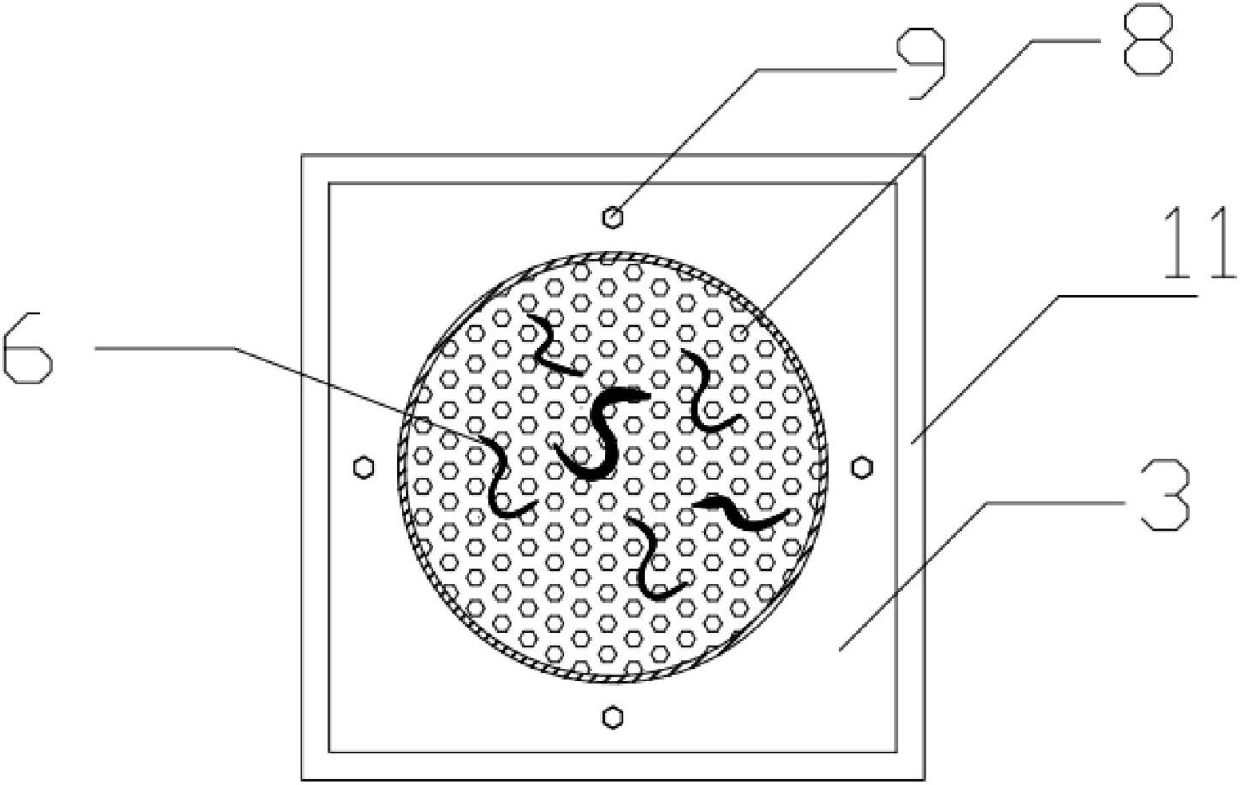

[0029] please see Figure 1-4 . The earthworm biological filter with wood filler provided by the present invention is composed of a conical water distributor at the top, a three-section filter bed reactor in the middle, and a sedimentation tank at the bottom from top to bottom.

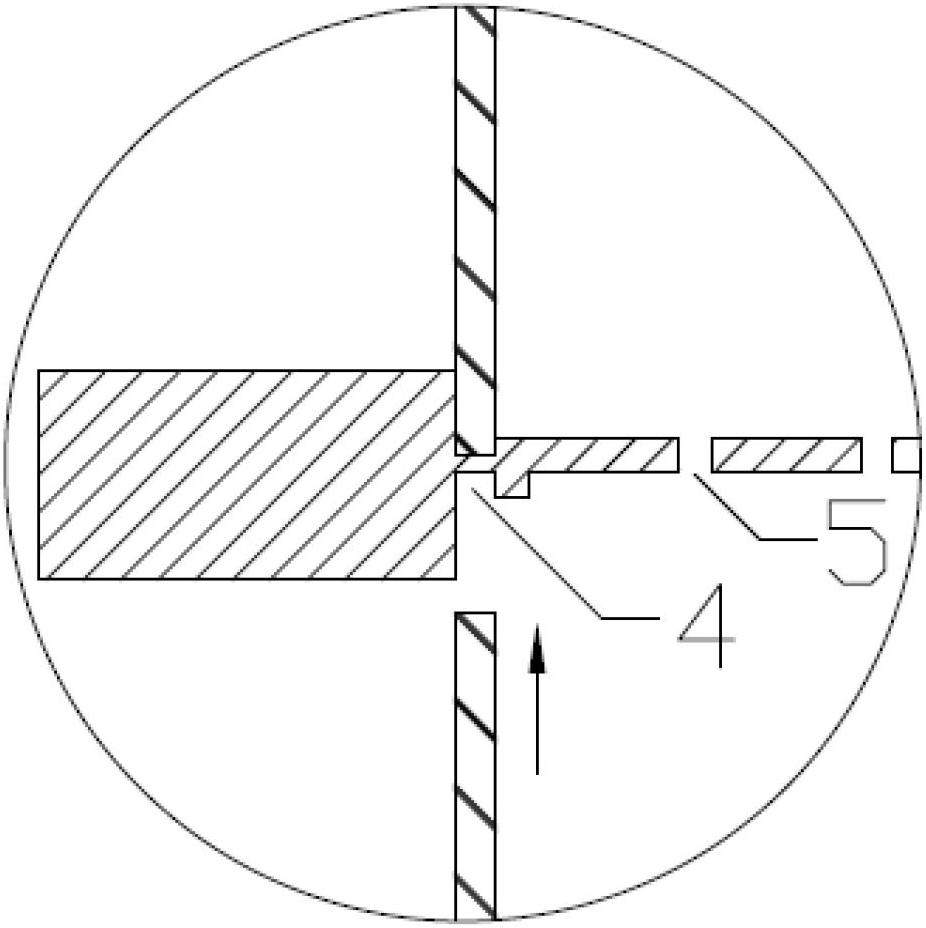

[0030] The shell of the conical water distributor is made of plexiglass with a thickness of 5mm. The diameter of the bottom is 300mm and the height is 350mm. There is a mud inlet 1 on the top and a perforated supporting plate 3 on the bottom. The through holes 5 of the supporting plate and the through holes 5 of the supporting plate are evenly distributed, and the aperture is 5 mm. The bottom of the supporting plate 3 is provided with a supporting plate groove 4 with an inner diameter of 305 mm and a depth of 30 mm, so that it can be firmly fixed on the on the filter bed reactor. The inside of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com