Emulsifier for emulsion explosive and preparation method for emulsifier

A technology for emulsifying explosives and emulsifiers, used in non-explosive/non-thermal components, explosives, offensive equipment, etc., can solve the problems of difficult emulsification, high price, poor emulsifying performance, etc., and achieve good stability, low cost, Excellent emulsifying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

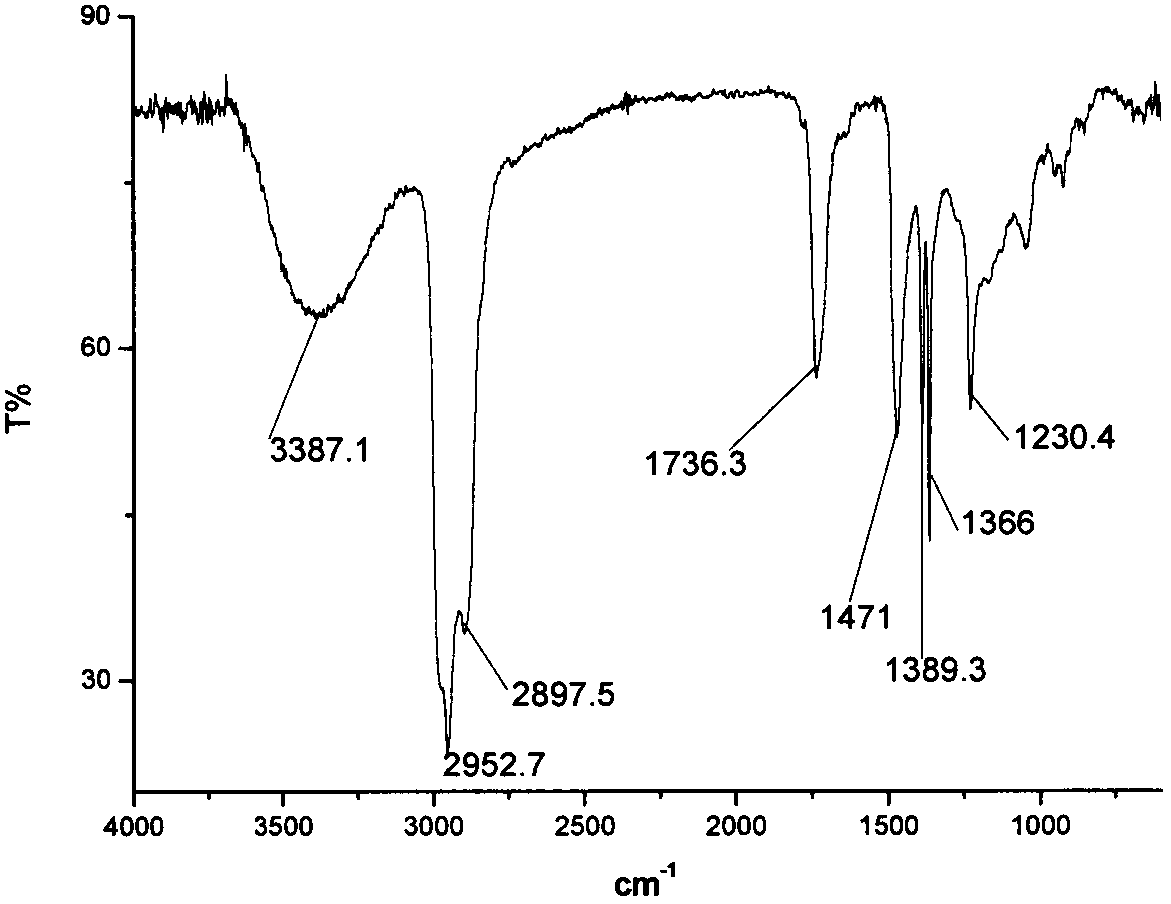

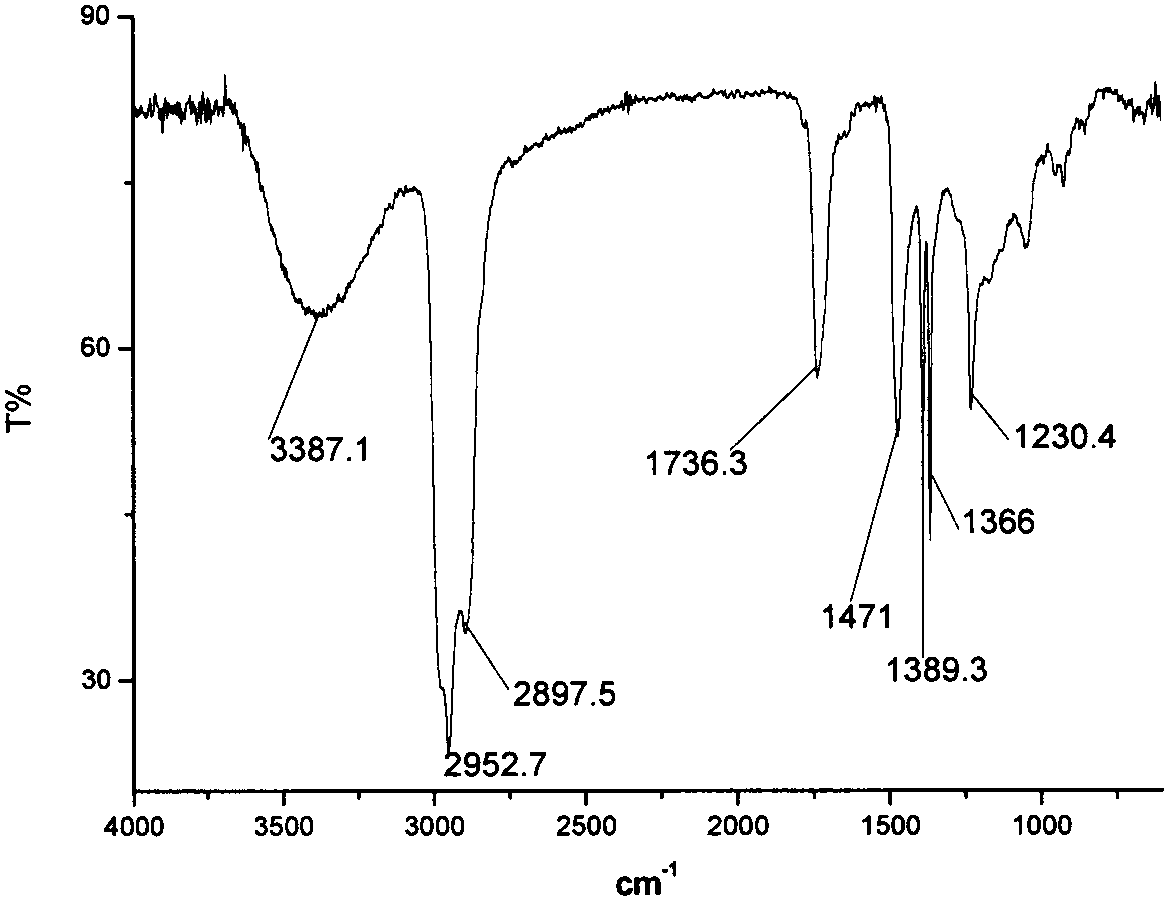

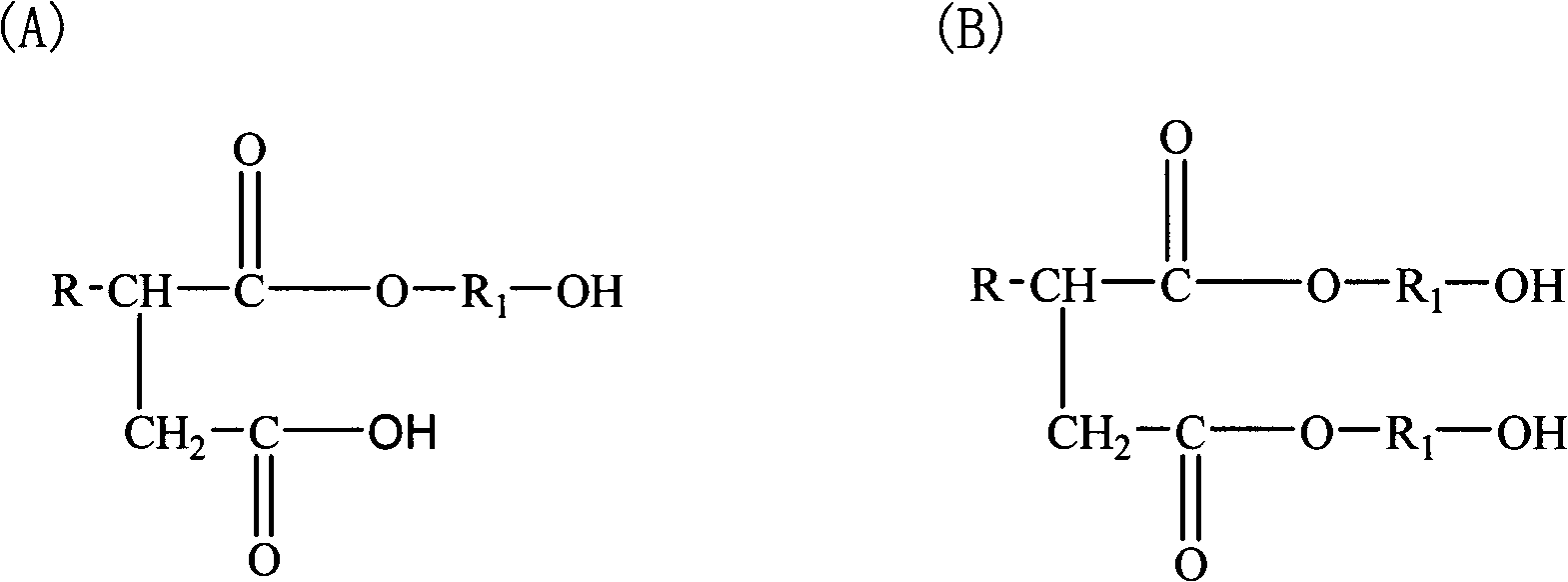

Image

Examples

Embodiment 1

[0024] Mix 80g of polyisobutylene succinic anhydride (Mn=1030g / mol) with a saponification value of 108.86mg / gKOH, 20g of hexaglycerol and 80g of n-octane. Under the protection of nitrogen, heat up to 80°C and stir for 4 hours. After the reaction , remove the solvent to obtain emulsifier P1 according to the present invention.

Embodiment 2

[0026] Mix 80 g of polyisobutylene succinic anhydride (Mn=1030 g / mol) with a saponification value of 108.86 mg / gKOH, 35 g of hexaglycerol and 100 g of n-octane, and add a catalyst whose mass (acid anhydride and polyglycerol total mass) fraction is 1.0%. For p-toluenesulfonic acid, under the protection of nitrogen, the temperature was raised to 120°C, and the reaction was stirred for 2.5 hours. After the reaction, the solvent was removed to obtain the emulsifier P2 of the present invention.

Embodiment 3

[0028] Mix 80g of polyisobutylene succinic anhydride (Mn=1030g / mol) with a saponification value of 108.86mg / gKOH, 70g of hexaglycerol and 120g of n-octane, and add a catalyst with a mass fraction of 1.5% (acid anhydride and polyglycerol total mass) For p-toluenesulfonic acid, under the protection of nitrogen, the temperature was raised to 130°C, and the reaction was stirred for 9.0 hours. After the reaction, the solvent and unreacted glycerin were removed to obtain the emulsifier P3 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com