Halogen-free flame-retardant polyphenyl ether composition

A polyphenylene ether and composition technology, applied in the field of polymer materials, can solve the problems of mechanical properties (impact strength) and reduced heat resistance, and achieve the effect of excellent mechanical properties and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

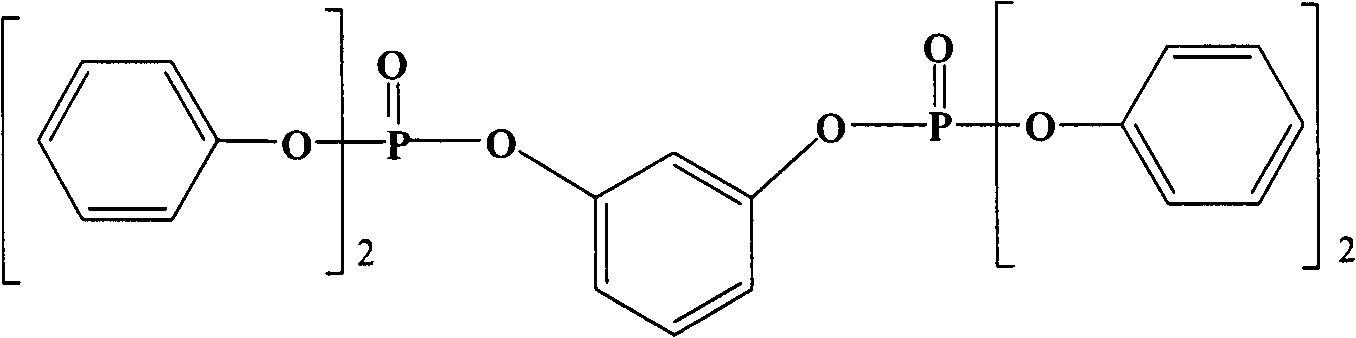

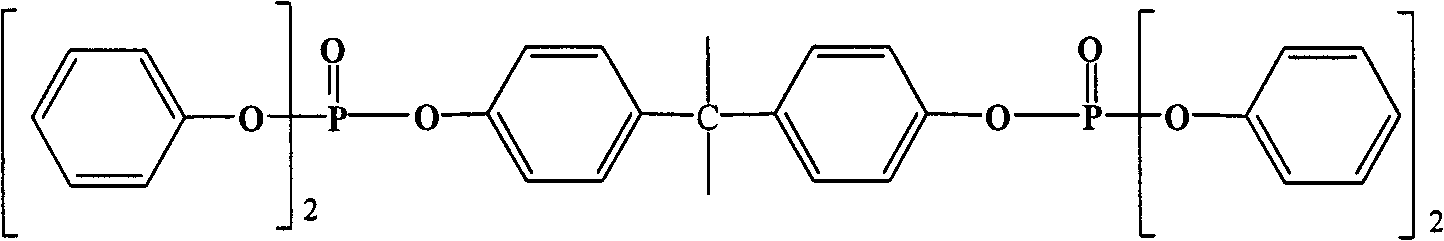

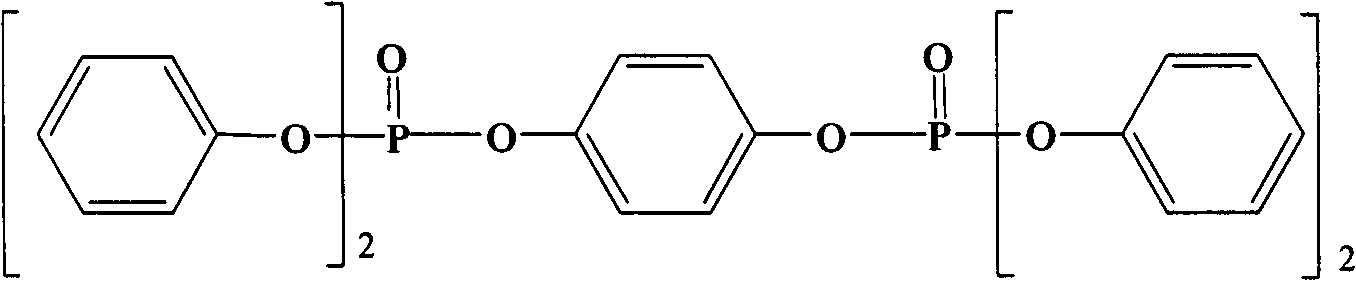

[0029] After mixing 63 parts of PPO and 27 parts of HIPS in a high-speed mixer by weight for 2 minutes, add them to the main hopper of a co-rotating parallel twin-screw extruder with a weight loss scale, feed with a weight loss scale, flame retardant RDP and BDP is heated to 90°C, mixed at a ratio of 5 / 5wt, and added from the downstream of the extruder with a liquid weight loss scale, and the ratio of main feed and liquid feed is adjusted to 90 / 10wt, and the raw materials are melted and extruded through the extruder Afterwards, it is cooled in a water tank, air-dried, and pelletized to obtain the composition.

[0030] In order to further improve the physical and mechanical properties of the composition, other modified materials can also be added, such as adding glass fiber to improve its tensile strength, modulus and heat resistance, and elastomers can also be selected to increase the impact strength of the composition .

Embodiment 2

[0032] After mixing 63 parts of PPO, 29 parts of HIPS and 3 parts of PDP with a high-speed mixer for 2 minutes by weight, they were added to the main hopper of a co-rotating parallel twin-screw extruder with a weight loss scale, and fed with a weight loss scale. Flame retardants RDP and BDP are heated to 90°C, mixed according to the ratio of 2 / 3wt, then added from the downstream of the extruder with a liquid weight loss scale, and the ratio of main feed and liquid feed is adjusted to 95 / 5wt, and the raw materials are extruded After being melted and extruded out of the machine, the composition is obtained by cooling in a water tank, air-drying, and pelletizing.

Embodiment 3

[0034] After mixing 55 parts of PPO, 30 parts of HIPS, 5 parts of elastomer SEBS and 7 parts of PDP in a high-speed mixer by weight for 3 minutes, they were added to the main hopper of a co-rotating parallel twin-screw extruder with a weight loss scale. Feed with a weight loss scale, heat the flame retardants RDP and BDP to 90°C, mix them at a ratio of 1 / 2 wt and add them from the downstream of the extruder with a liquid weight loss scale, adjust the ratio of main feed and liquid feed to 97 / 3wt, the raw materials are melted and extruded by an extruder, cooled in a water tank, air-dried, and pelletized to obtain the composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com