Spheroidizing annealing furnace and annealing process for steel wire

An annealing process and annealing furnace technology, applied in furnaces, heat treatment furnaces, manufacturing tools, etc., can solve problems such as the entry of thermal insulation cotton and refractory bricks, affecting the annealing quality of steel wires in the inner barrel, and affecting the annealing quality of steel wires in the inner barrel, etc. Effect of decarburization and improvement of annealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

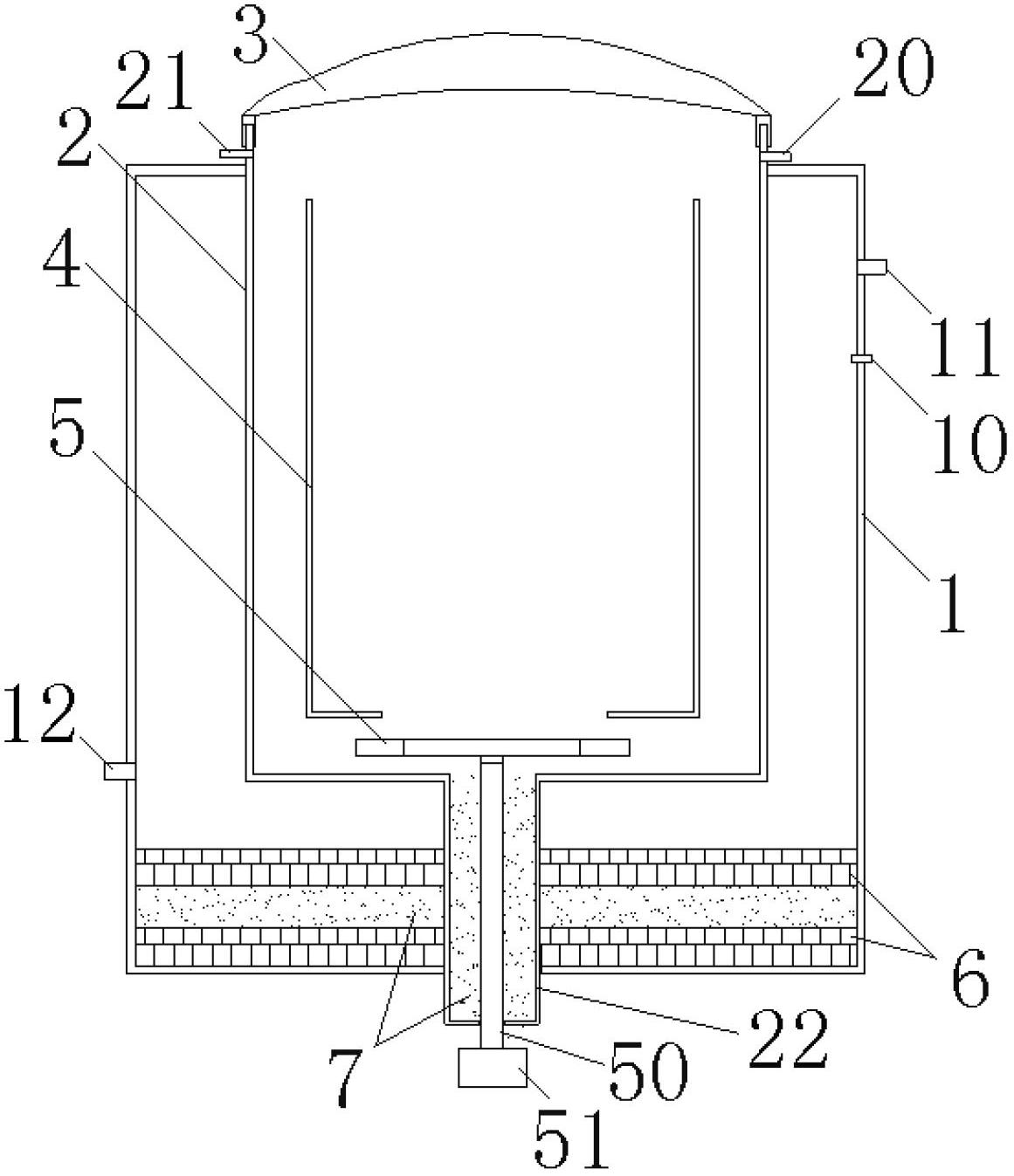

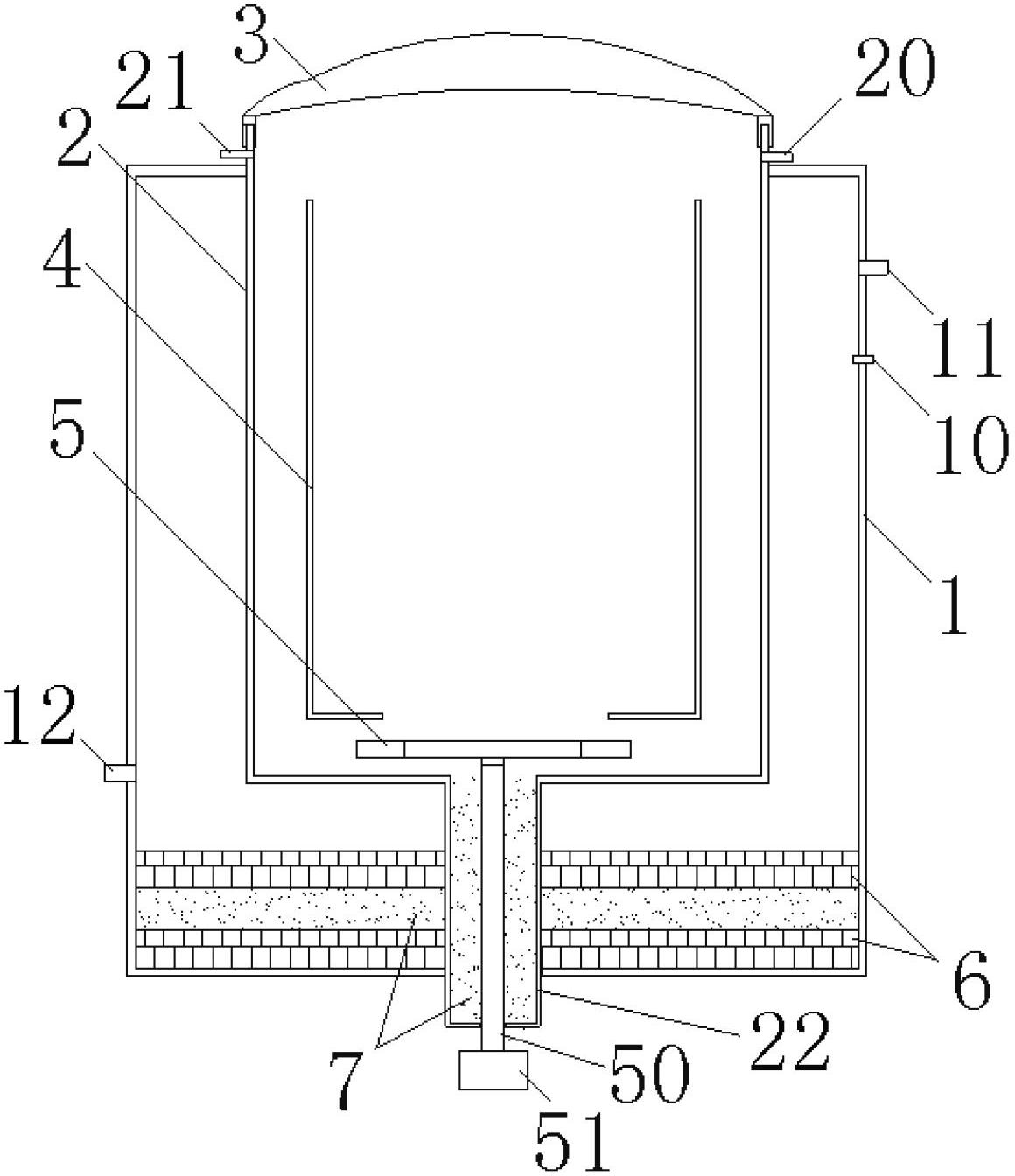

[0025] Such as figure 1 As shown, a steel wire spheroidizing annealing furnace includes a furnace body 1, an inner barrel 2 and a furnace cover 3, the inner barrel 2 is arranged in the furnace body 1, the furnace cover 3 is matched with the upper part of the inner barrel 2, and the outer wall of the inner barrel 2 and the furnace body 1 The inner wall forms a combustion heating chamber for heating the inner barrel. Ten gas heating points 10 are uniformly distributed on the furnace wall of the furnace body 1, and the furnace body 1 is provided with a furnace body air inlet 12 and a furnace body exhaust port 11 to facilitate ventilation and cooling. A fan is provided in the inner tub 2, and a motor 51 for driving the fan is provided below the furnace body 1. Preferably, the fan is a convection f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com