Method for smelting ultra-pure austenite nuclear grade stainless steel

A technology of austenite and stainless steel, applied in the smelting field of ultra-pure austenitic core grade stainless steel, can solve the problems of unusable and high harmful elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

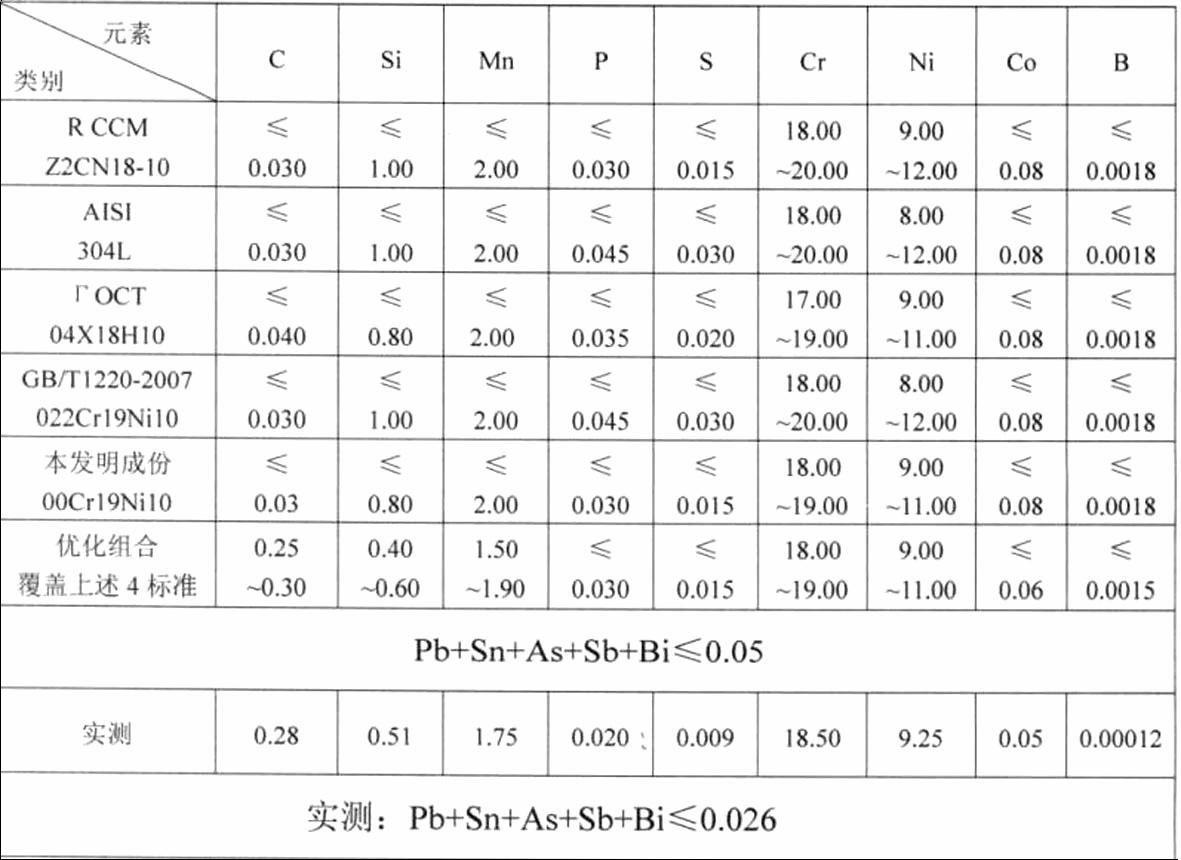

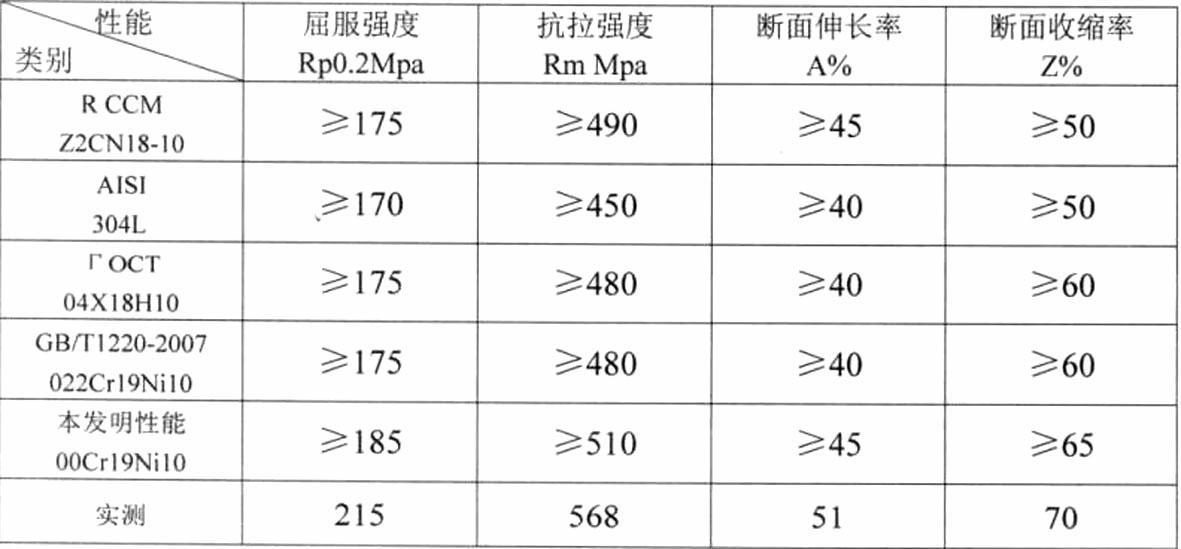

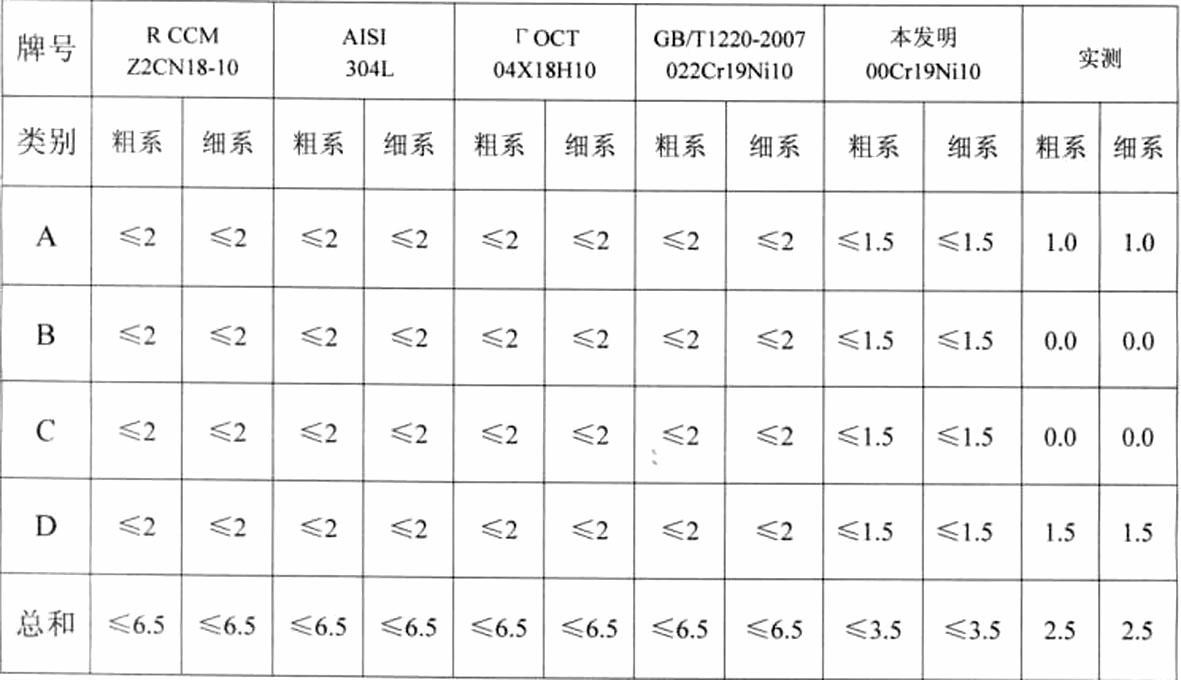

[0022] Embodiment: the processing and production process of the present embodiment is as follows:

[0023] 1. Select high-quality raw materials, choose micro-carbon ferrochrome with carbon content ≤ 0.03; use 0# nickel plate, original eco-scrap high-quality top material for nickel plate, which has few impurities and low harmful elements, especially low Co and B content.

[0024] 2. Purification treatment of raw materials, charge and ferroalloy: Pickling high-quality alloy element materials, micro-carbon ferrochromium, VCr3, 0# nickel plate + 70% original ecological scrap steel, and then cleaning again with clean water (removing residual acid liquid), and drying Dry, reduce moisture to prevent gas formation. The purpose of this step is to be able to purify the molten steel at source.

[0025] 3. Purify the hearth and buns of the steel furnace, which is the step of washing the furnace, that is, before refining the steel grade of this embodiment, first refine the first furnace t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com