Production method of high cleanliness bearing steel

A production method and high cleanliness technology, applied in the field of iron and steel metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

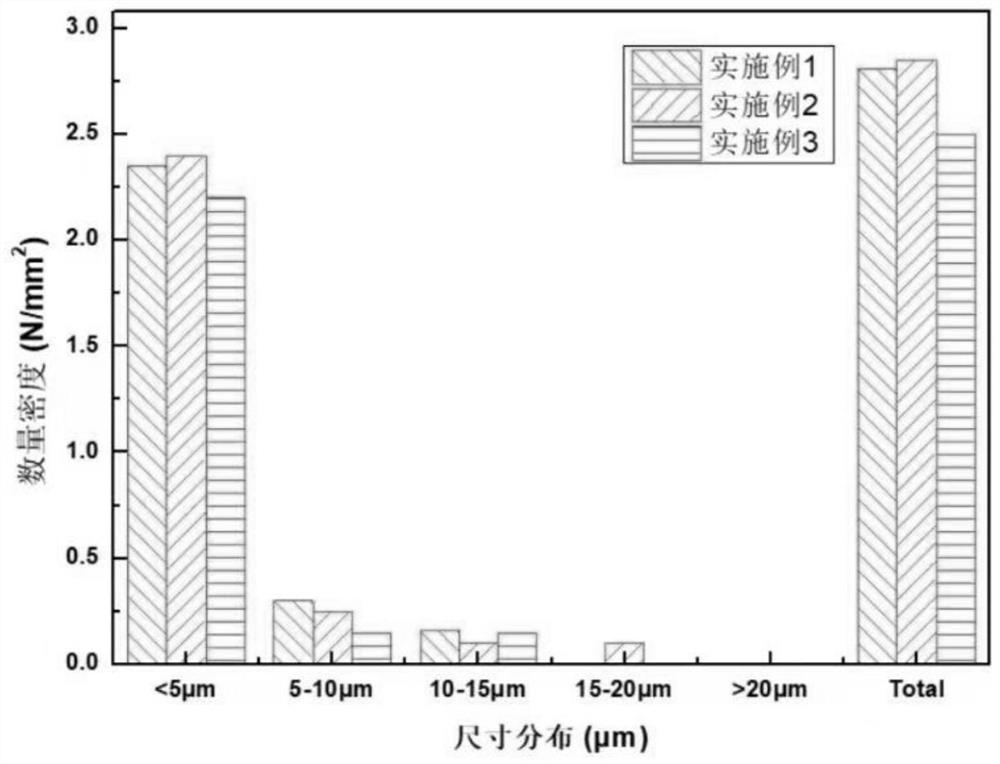

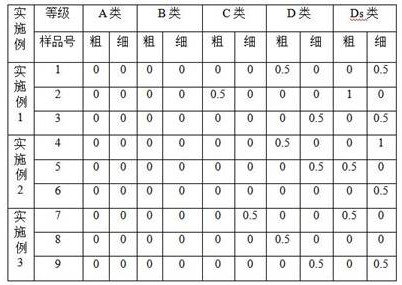

Embodiment 1

[0053] The embodiment of the present invention provides a production method of high cleanliness bearing steel, the steps are as follows:

[0054] (1) BOF blowing: Add 90t of molten iron (temperature 1240°C) and 10t of steel scrap into a 100t top-bottom re-blowing converter, then shake the converter upright, lower the top lance of the converter to 1.8m from the liquid surface of the molten pool, and set the top lance to For oxygen blowing mode, according to the oxygen supply intensity 3.0NM 3 Oxygen is blown into the molten pool of the converter at / t min, and nitrogen is blown in through the breathable brick at the bottom of the converter at the same time, the flow rate of nitrogen is 25L / min; The content is monitored and the rate of change of CO content is calculated:

[0055] R=(W t1+5 -W t1 ) / 5, where W t1 is the CO content in the flue gas detected at time t1, W t1+5 is the CO content in the flue gas detected after an interval of 5s from t1;

[0056] After testing, wh...

Embodiment 2

[0067] The embodiment of the present invention provides a production method of high cleanliness bearing steel, the steps are as follows:

[0068] (1) BOF blowing: Add 180t of molten iron (temperature 1300°C) and 25t of steel scrap into a 200t top-bottom combined blowing converter, then shake the converter upright, lower the converter top lance to 2.0m from the liquid surface of the molten pool, and set the top lance to For oxygen blowing mode, according to the oxygen supply intensity 4.5NM 3 Oxygen is blown into the converter molten pool at / t min, and nitrogen is blown in through the breathable brick at the bottom of the converter at the same time. The nitrogen flow rate is 50L / min; The content is monitored and the rate of change of CO content is calculated:

[0069] R=(W t1+5 -W t1 ) / 5, where W t1 is the CO content in the flue gas detected at time t1, W t1+5 is the CO content in the flue gas detected after an interval of 5s from t1;

[0070] After testing, when the blo...

Embodiment 3

[0081] The embodiment of the present invention provides a production method of high cleanliness bearing steel, the steps are as follows:

[0082] (1) BOF blowing: Add 145t of molten iron (temperature 1360°C) and 16t of scrap steel into a 150t top-bottom re-blowing converter, then shake the converter upright, lower the top gun of the converter to 1.6m from the liquid surface of the molten pool, and set the top gun to For oxygen blowing mode, according to the oxygen supply intensity 2.7NM 3 Oxygen is blown into the molten pool of the converter at / t min, and nitrogen is blown in through the breathable brick at the bottom of the converter at the same time. The nitrogen flow rate is 100L / min; The content is monitored and the rate of change of CO content is calculated:

[0083] R=(W t1+5 -W t1 ) / 5, where W t1 is the CO content in the flue gas detected at time t1, W t1+5 is the CO content in the flue gas detected after an interval of 5s from t1;

[0084] After testing, when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com