High-temperature resistant micropore silicon carbide fiber and preparation method thereof

A technology of microporous silicon carbide and high temperature resistance, which is applied in the fields of fiber chemical characteristics, melt spinning, chemical post-treatment of rayon, etc. It can solve the problems of poor pore structure stability and low crystallinity, and achieve high temperature resistance. The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

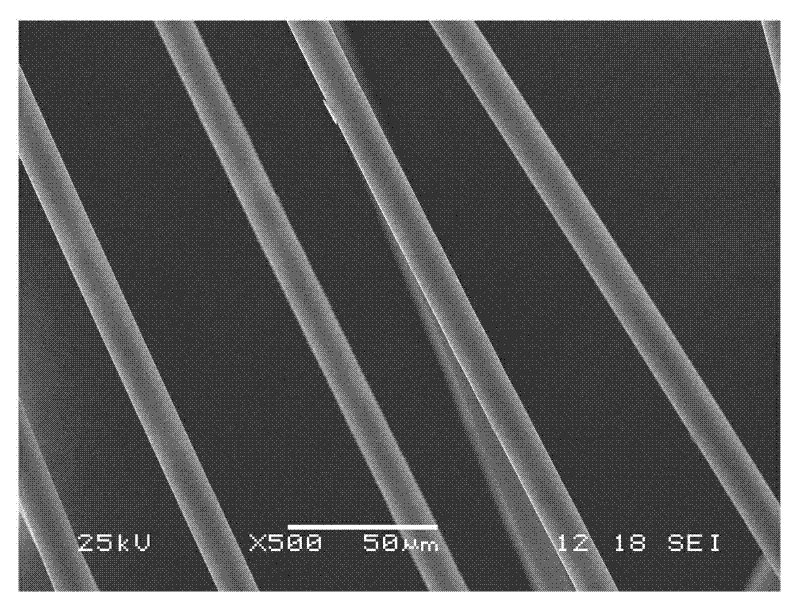

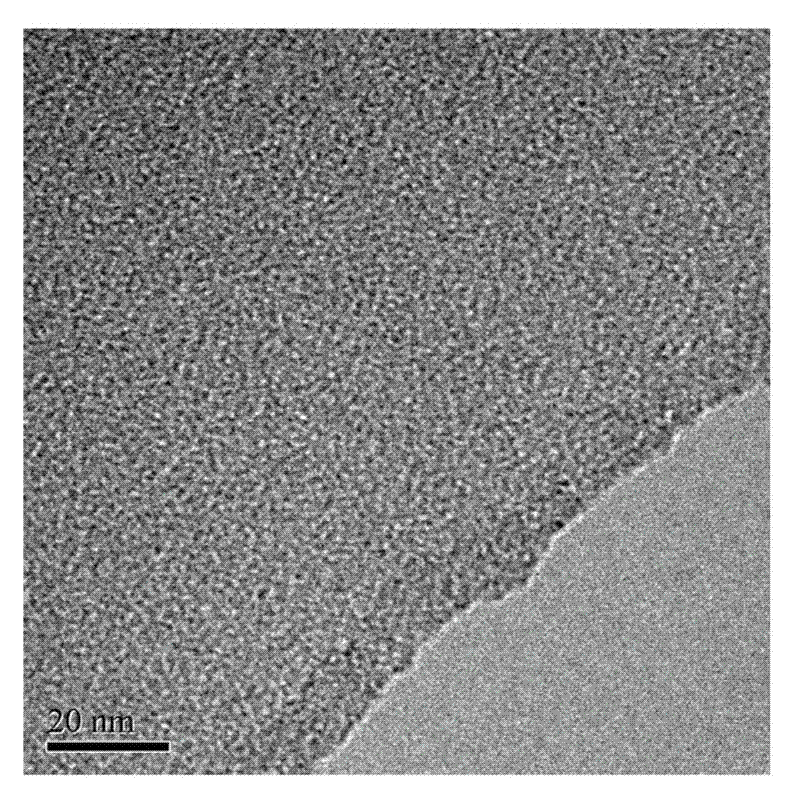

[0022] The Si content of the microporous silicon carbide fiber in this embodiment is 69.6wt%, the C content is 30.2wt%, the Si:C atomic ratio is 0.99, and the O content is 0.2wt%. 81vol% of the capacity, the specific surface area is 1610m 2 / g, the average pore diameter is 1.72nm. The specific surface area after 10h of use at 1000°C in nitrogen is 1580m 2 / g, the pore structure did not change significantly.

[0023] Preparation: Put 10g of PCS in a melt spinning device, heat it to 280°C under the protection of nitrogen with a purity of 99.999% and perform defoaming treatment, then melt spin at a speed of 100m / min at 240°C and 0.5MPa , to obtain the original silk; put the original silk in the oxidation furnace, heat it to 200 °C at 15 °C / h in the air atmosphere, and keep it warm for 3 hours; use ZnCl to infusible fiber 2 Soak the saturated solution for 20 hours, dry it, place it in a high-temperature furnace protected by nitrogen with a purity of 99.999%, and raise the tempe...

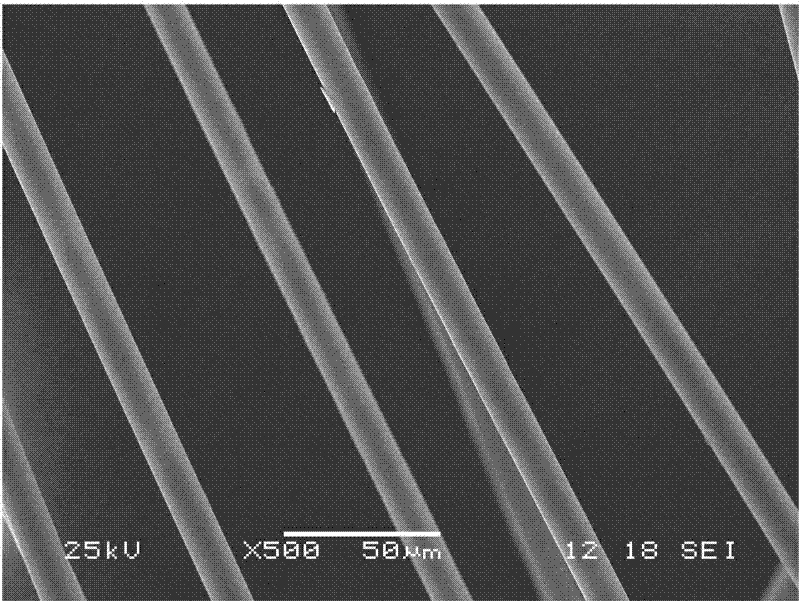

Embodiment 2

[0026] The Si content of the microporous silicon carbide fiber in this example is 69.0wt%, the C content is 30.8wt%, the Si:C atomic ratio is 0.99, and the O content is 0.2wt%. 83vol% of the capacity, the specific surface area is 1034m 2 / g, the average pore diameter is 1.25nm. The specific surface area after 10h of use at 1000°C in nitrogen is 1010m 2 / g, the pore structure did not change significantly.

[0027] Preparation: the only difference from Example 1 is that the activator is H 3 PO 4 .

Embodiment 3

[0029] The Si content of the microporous silicon carbide fiber in this example is 70.1wt%, the C content is 29.8wt%, the Si:C atomic ratio is 1.00, and the O content is 0.1wt%. The capacity is 85vol%, and the specific surface area is 1728m 2 / g, the average pore diameter is 1.76nm. The specific surface area after using in nitrogen at 1000℃ for 10h is 1680m 2 / g, the pore structure did not change significantly.

[0030] Preparation: the only difference from Example 1 is that the activator is ZnCl 2 and H 3 PO 4 mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com