Measuring method for relative liquid level position of silicon melt in Czochralski silicon single crystal furnace

A technology of relative position and measurement method, which is applied in crystal growth, single crystal growth, single crystal growth, etc., and can solve problems such as poor precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

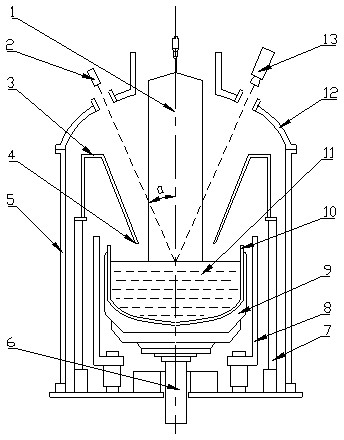

[0015] Below in conjunction with accompanying drawing, describe the specific embodiment of the present invention.

[0016] The method for measuring the relative position of the silicon melt level of the Czochralski silicon single crystal furnace comprises steps as follows:

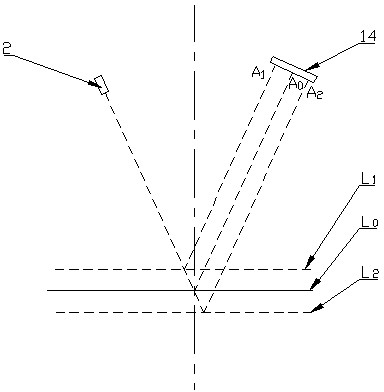

[0017] (1) The laser source 2 installed in the observation window on the furnace cover 12 of the silicon single crystal furnace emits laser light, the diameter of the laser spot is 0.1-1 mm, and the laser light is reflected by the surface of the silicon melt 11 and then installed on the furnace cover of the silicon single crystal furnace 12 Obtained by the CCD camera 13 of the observation window on the other side, and the signal is transmitted to the computer system after analog-to-digital conversion;

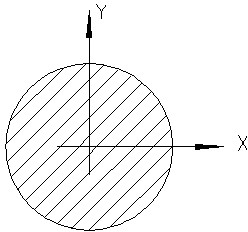

[0018] (2) The multi-directional random vibration of the surface of the silicon melt enables the CCD camera 13 to obtain a circular or nearly circular laser image within a set sampling period of 5-20 secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com