Spinning device of regenerated polyester fibers

A spinning device and recycled polyester technology, applied in textiles, papermaking, spinneret assemblies, etc., can solve the problems of limited resources and high cost, and achieve the effects of good uniformity, low cost and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

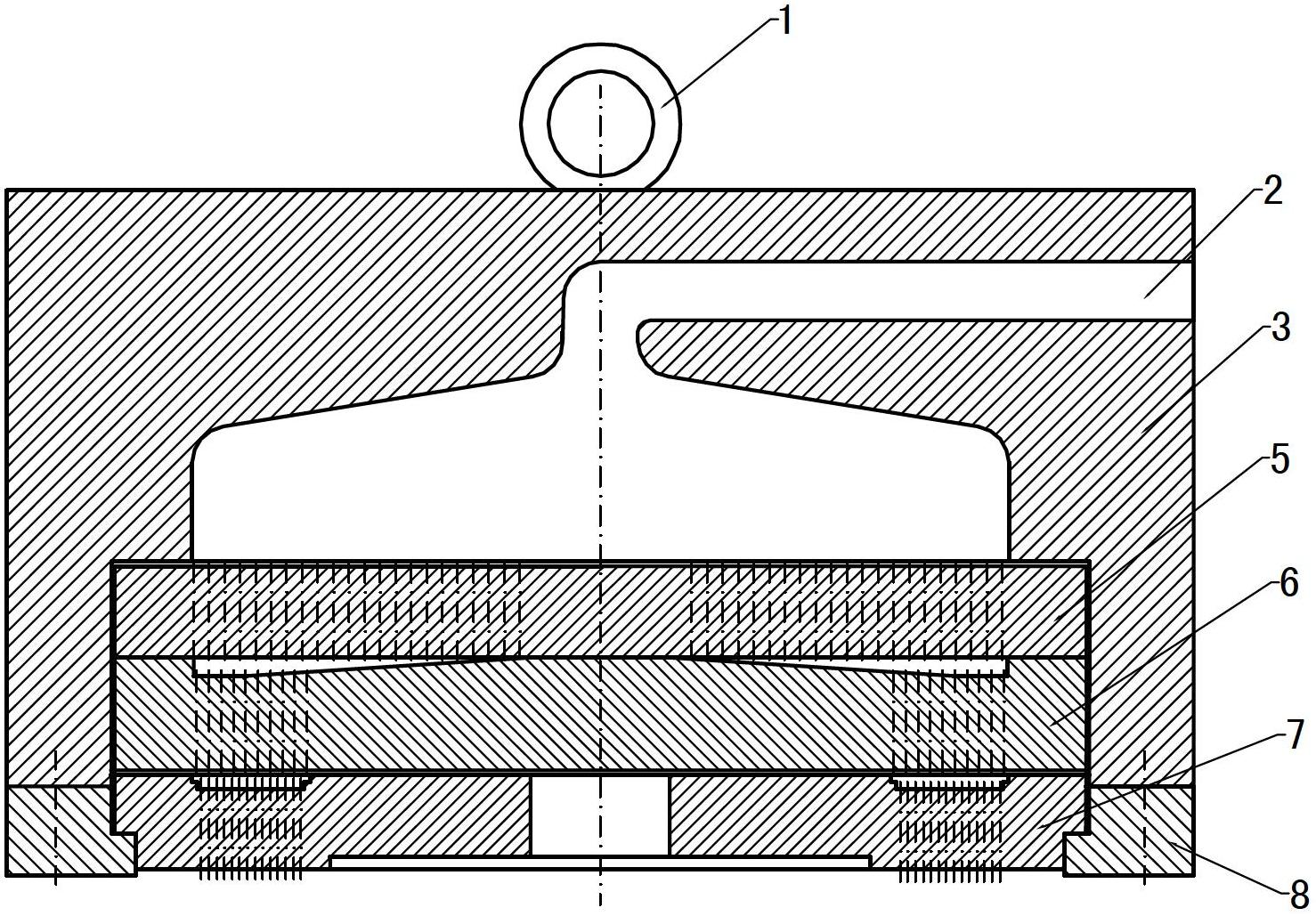

[0013] refer to figure 1 , the existing spinning assembly is composed of an assembly headgear 3, a pressure plate 5, a distribution plate 6 and a spinneret 7, and the pressure plate 5, the distribution plate 6 and the spinneret 7 are fixedly connected to the assembly headgear 3 through a pressure ring 8 Below, the melt inlet 2 is arranged on the side of the assembly headgear 3, and the upper part of the assembly headgear 3 is provided with a lifting ring 1.

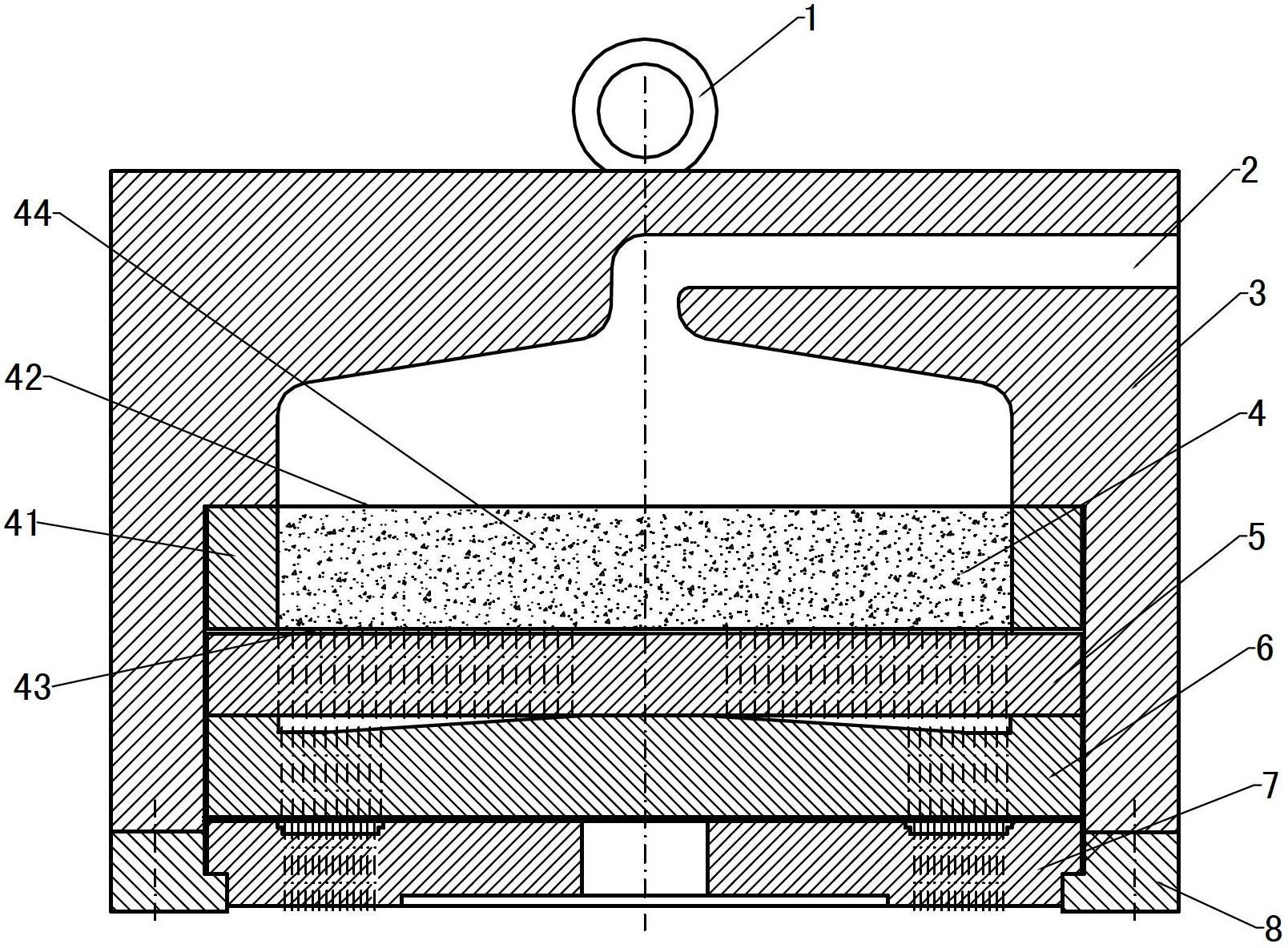

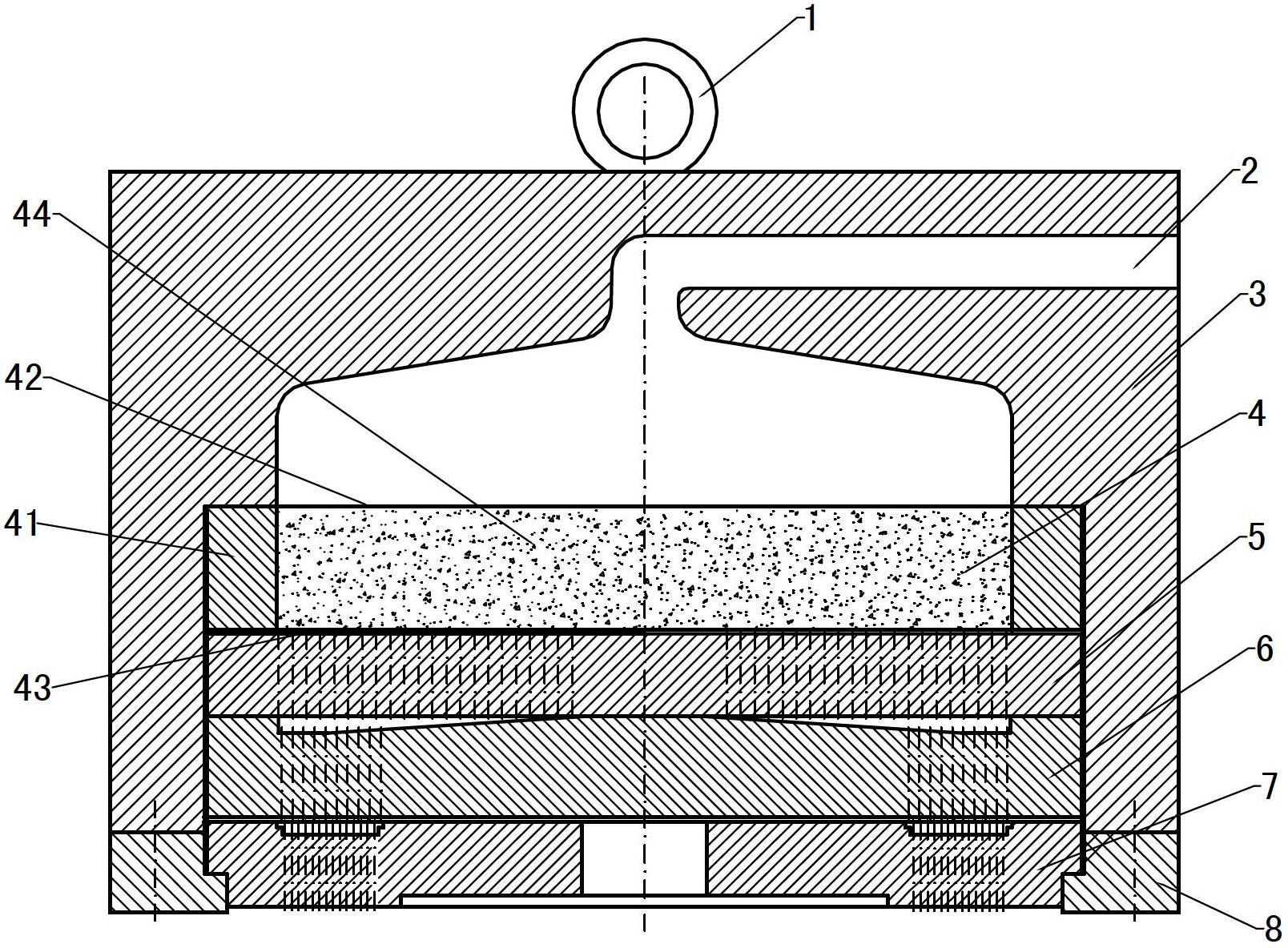

[0014] refer to figure 2 The difference between the spinning pack described in this embodiment and the spinning pack of the prior art is:

[0015] a) Add a sea sand filter 4 in the spinning assembly, the sea sand filter 4 consists of a positioning ring 41, a 250-mesh metal filter 42 arranged above the positioning ring, a 250-mesh metal filter 43 arranged below the positioning ring and Sea sand 44 is filled between the two layers of metal filter screens. The design value of the thickness of the sea sand filter layer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap