Carbon dioxide pressurizing conveying device

A technology for carbon dioxide and pressurized transportation, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc. It can solve the problems of high noise of the piston rod of the pressurized cylinder, accelerated wear of the piston rod, and high reciprocating stroke frequency, so as to improve The effect of heat exchange efficiency, prolonging service life and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

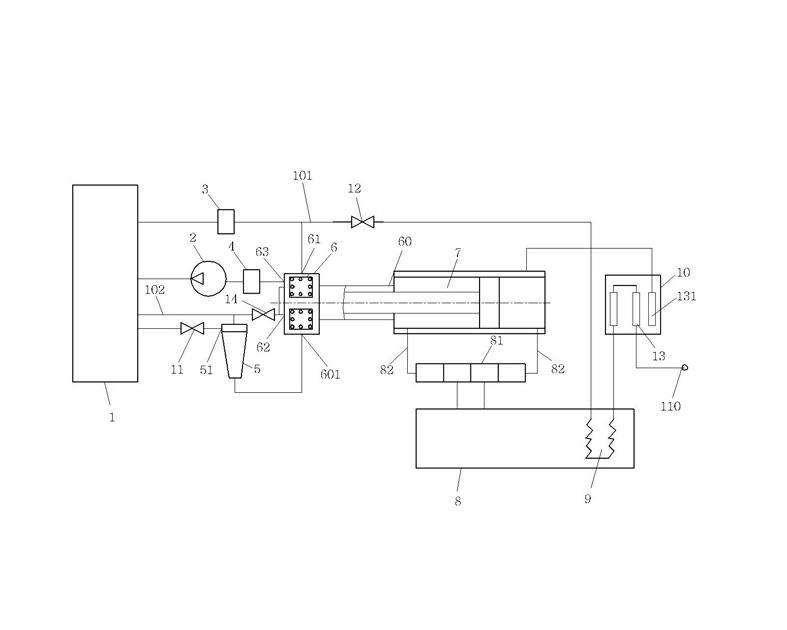

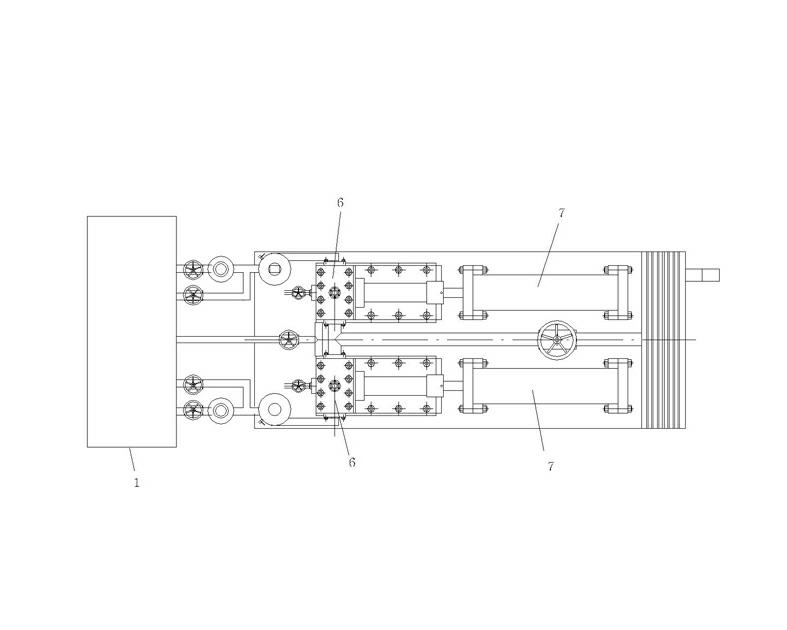

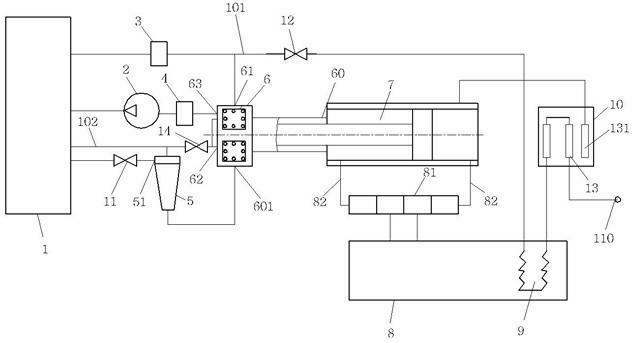

[0015] Such as figure 1 , figure 2 As shown, the present invention includes a carbon dioxide storage tank 1, a shielded pump 2, a high-voltage electronically controlled follow-up valve 3, a low-voltage electronically controlled follow-up valve 4, a liquid-gas separator 5, a carbon dioxide booster pump 6, a booster cylinder 7, a hydraulic general 8. The heat exchanger and the auxiliary heating tank 10, the carbon dioxide storage tank 1 is connected to the input end 51 of the liquid-gas separator through the input shut-off valve 11, and the liquid-phase output end 52 of the liquid-gas separator is connected to the input end 601 of the carbon dioxide booster pump. The high-pressure pipeline 101 of the first output end 61 of the carbon dioxide booster pump passes through the heat supply unit 13 of the air-energy heat pump heater of the auxiliary heating box 10 outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com